5-2 X-Series Work Platform

Troubleshooting

Section

Test Steering Switch for continuity.

Replace if faulty.

Test Diode. Replace if faulty.

Test Steer Right Solenoid. If the

proper voltage is present and the coil

is not magnetized, replace.

Test Steering Switch for continuity.

Replace if faulty.

Test Diode. Replace if faulty.

Test Steer Left Solenoid. If the proper

voltage is present and the coil is not

magnetized, replace.

Check continuity of Drive/Lift Switch.

Replace if faulty.

Test Relay (R2). Replace if faulty.

Inspect Drive Motor shafts, hubs, and

keys.

Check hydraulic pressure being

delivered to the Drive Motors. If

sufficient, replace Drive Motors.

Adjust and test the Level Sensor,

replace if faulty.

Check Relay, replace if faulty.

Check Pump, replace if faulty.

Adjust and test Controller.

Check continuity of Drive/Lift Switch.

Replace if faulty.

Check continuity of Down Limit

Switch. Replace if faulty.

Test coil and valve. If faulty, replace.

Check continuity of switch, replace if

faulty.

Check operation, adjust if necessary.

Replace if required.

Check operation, replace if required.

Test Relay (R2). Replace if faulty.

Check the Drive/Lift Valve. If the

spool is not shifting, replace the valve.

Check pressure of Counterbalance Valves.

Replace or reset valves as required.

Test Relay (R2) Replace if faulty.

Check operation of Controller switch.

Replace if required.

Test Relay (R2). Replace if faulty.

Check the Drive/Lift Valve. If proper

voltage is present and coil is not

magnetized replace the coil, if the

spool is not shifting, replace the valve.

Test diode, replace if faulty.

Check pressure of Counterbalance Valves.

Replace or reset valves as required.

Test Relay (R2). Replace if faulty.

Check operation of Controller switch.

Replace if required.

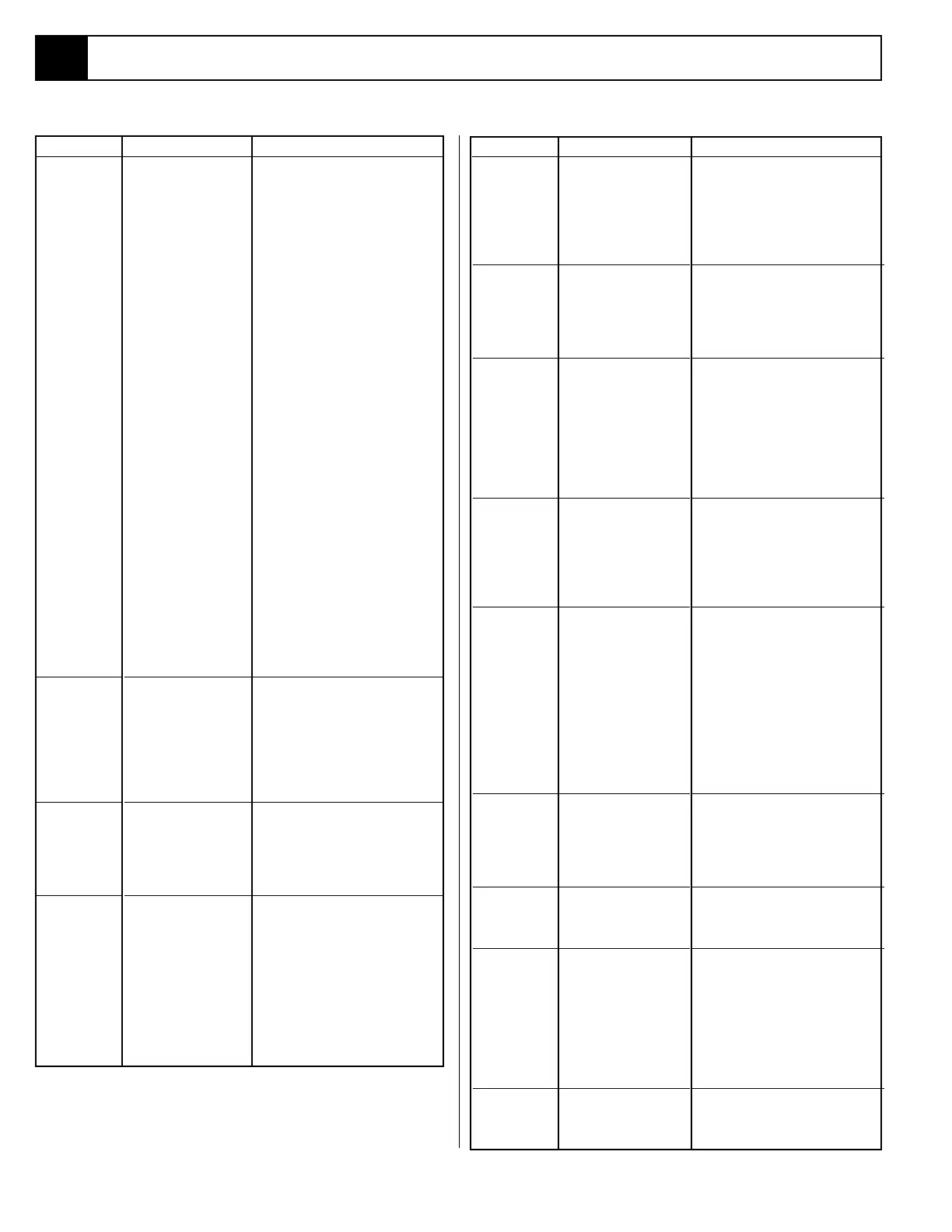

Table 5-1: Troubleshooting

Check control circuit Circuit Breaker.

Reset if open (button out).

Check 175 amp Electric Motor Fuse.

Replace if blown.

Check the voltage output of the

Battery Charger. If less than 24 VDC,

repair or replace.

After completely charging Batteries,

test each Battery. Replace as required.

While operating the steering function,

check voltage across the Electric

Motor terminals. If 24 VDC is

present, replace the Motor.

While operating the steering, check

voltage across the coil terminals of

Motor Relay. If no voltage is present,

proceed with step 7. If 20 VDC or

more, check continuity across the

contact terminals of Motor Relay

while still operating the steering

function. If there is no continuity,

replace the faulty Motor Relay.

With the Emergency Stop Switch in

the ON position, check continuity

across the contacts. If none, replace.

Check continuity of switch, replace if

faulty.

Test relay, replace if faulty.

Check continuity of switch, replace if

faulty.

Check operation, adjust if necessary.

Check hydraulic fluid level, top off as

required.

Check pressure and delivery of the

Hydraulic Pump. Replace if required.

Check operation, adjust if necessary.

Replace if required.

Check operation, replace if required.

Check operation. Adjust or replace if

required.

With 0 voltage at the coil terminals of

the Motor Relay (R1) check continuity

across the contact terminals. If there is

continuity, replace the Motor Relay.

Test Steering Switch for continuity.

Replace if faulty.

Inspect all steering components.

Replace damaged parts.

Inspect Steering Valve. If spool is

sticking, replace.

Check Steering Cylinder for leakage

from one port to another. Repair as

required.

Adjust the relief valve, if not

adjustable replace.

All functions

inoperable,

Electric Motor

does not start.

All functions

inoperable.

Electric motor

starts when

control is

actuated.

Electric Motor

continues to

run after

controls are

returned to the

OFF position.

Steering

inoperable or

functions

sluggishly.

TROUBLE

PROBABLE CAUSE

REMEDYTROUBLE

PROBABLE CAUSE

REMEDY

1. Open control circuit

Circuit Breaker (CB).

2. Blown Electric Motor

Fuse (FU1).

3. Faulty Battery

Charger.

4. Faulty Battery(ies)

(BAT).

5. Faulty Electric Motor

(MOT).

6. Faulty Motor Relay

(R1).

7. Emergency Stop

Switch failed open.

8. Faulty Down Limit

Switch (LS1).

9. Faulty Tilt Alarm

Relay (R3).

10. Faulty

Interlock Switch.

11. Faulty

Controller.

1. Hydraulic Reservoir

low.

2. Faulty Hydraulic

Pump (PMP).

3. Faulty Controller

(CONT).**

4. Proportional Valve

(V9,SOL8).**

Motor Relay (R1)

contacts fused

together.

1. Faulty Steering

Switch.

2. Mechanical damage.

3. Steering Valve (V1)

stuck.

4. Steering Cylinder

(CYL1) piston seal

leaking.

5. Steering Relief (RV2).

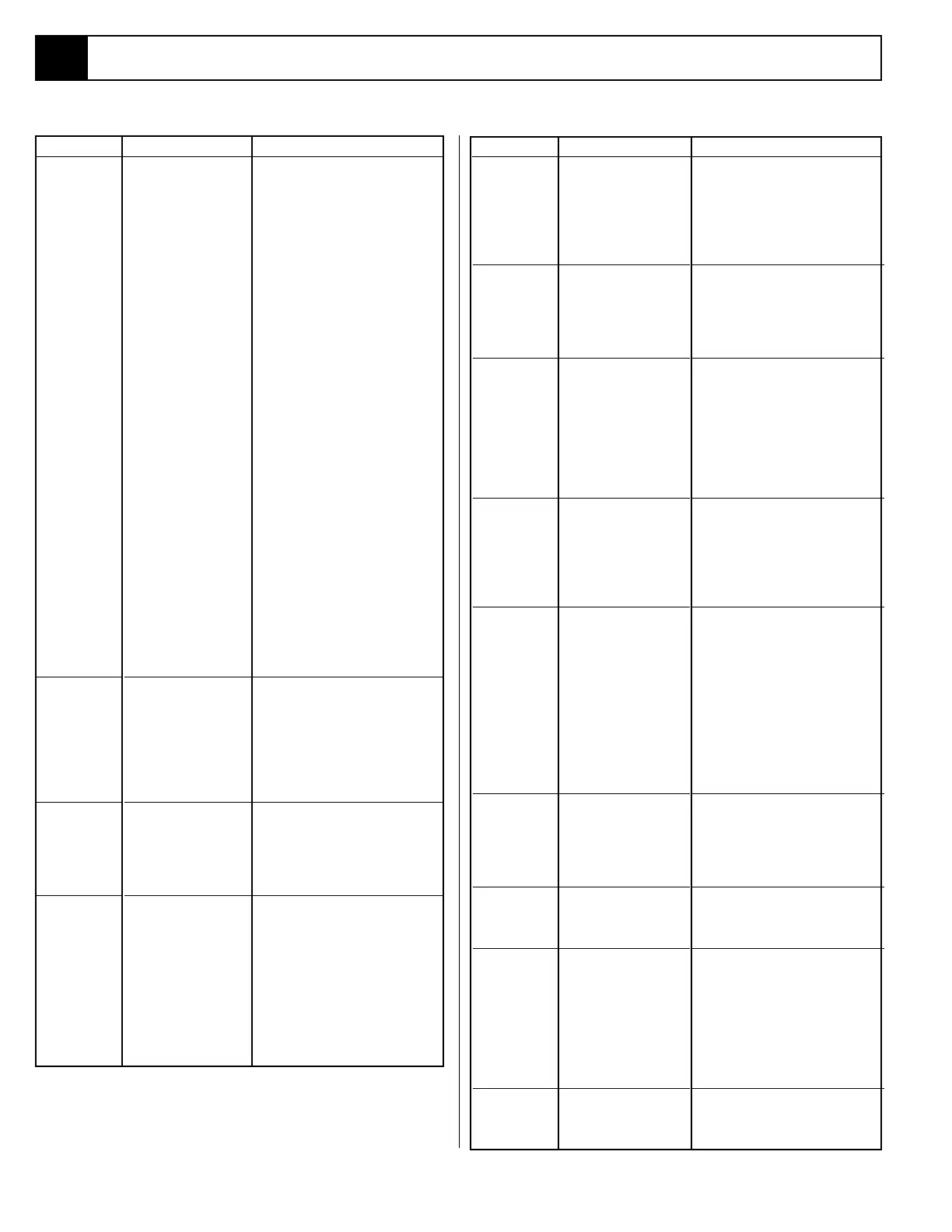

5.1

Work platform

will not steer

right.

Work platform

will not steer

left.

Work platform

will not drive

FORWARD or

REVERSE. Lift

function

operable.

Work Platform

will not drive

while elevated.

No high speed

drive.

No drive FWD

but drives in

REV. Lift

function

operable.

No drive FWD

but drives in

REV. No lift

function.

No drive REV

but drives in

FWD. Lift

function

operable.

No drive REV

but drives in

FWD. No

down function.

1. Faulty Steering

Switch.

2. Faulty Diode (D1).

3. Faulty Steer Right

Solenoid (SOL1).

1. Faulty Steering

Switch.

2. Faulty Diode (D2).

3. Faulty Steer Left

Solenoid (SOL2).

1. Faulty Drive/Lift

Selector Switch (S5).

2. Faulty Drive/Lift Relay

(R2).

3. Mechanical failure.

4 . Worn Drive Motors (

MOT1, MOT2).

1. Level Sensor (SNSR)

out of adjustment or

faulty.

2. Faulty Relay.

3. Low Segment of

pump faulty.

4. Controller Adjustment**

1. Faulty Drive/Lift

Switch.

2. Faulty Down Limit

Switch (LS1).

3. Faulty High Speed

Coil/Valve (SOL7/V6).*

4. Faulty Controller

Switch (S4).*

5. Faulty Controller

(CONT).**

6. Proportional Valve

(V9,SOL8).**

1. Faulty Drive/Lift Relay

contacts (R2).

2. Faulty Forward/

Reverse Valve (V5).

3. Faulty Counterbal-

ance Valves (V2, V3).

1. Faulty Drive/Lift Relay

contacts (R2)

2. Faulty Up/Forward

Controller Switch (S9).

1. Faulty Drive/Lift Relay

contacts (R2).

2. Faulty Forward/

Reverse Solenoid/

Valve (SOL3/V5).

3. Faulty diode (D3).

4. Faulty Counterbalance

Valves (V2, V3).

1. Faulty Drive/Lift Relay

contacts (R2).

2. Faulty Down/Reverse

Controller Switch (S2).

Loading...

Loading...