a"&a1-_11a-%@

,]imum (

recommended

) tyre pressure: ML* (LOO;S or L;OO or L;OM or R;LOO,-)

,*imum

92

allowed tyre pressure: LY*<LMO;L or L;MO or L;MM or R;LMO,=

In case of permanent tyre pressure release, check and repair possible tyre defect.

&""1%"---%%%!

3.5.2 MACHINE LUBRICATION

(%%"1"%&%%%"!

&""1%"---%%%!

Smooth and easy movement of all mechanical parts requires adequate lubrication. Several drops of oil are usually sufficient (e.g. Bicycle

oil). The gearbox is filled with sufficient amount of oil during manufacturing and it does not require filling during the whole machine life.

3.5.2.1 ENGINE OIL EXCHANGE

Follow the engine user manual instructions. If you use the cutter in a dusty environment, shorten the exchange period by half. When

pouring the oil out of the engine tilt the cutter on its filler and oil dipstick side or dismantle the whole engine.

&""1%"---%%%!

3.5.2.2 LUBRICATING POINTS

There is no need to dismount any covers from the machine when lubricating the cables on the handlebars. You can reach other

lubricating points after dismounting the plastic covers. You can use any kind of engine, transmission or spray oil. Any kind of lubricant

grease for water pumps is fully sufficient. For its application, however, it is usually necessary to dismantle the appropriate sliding sealing.

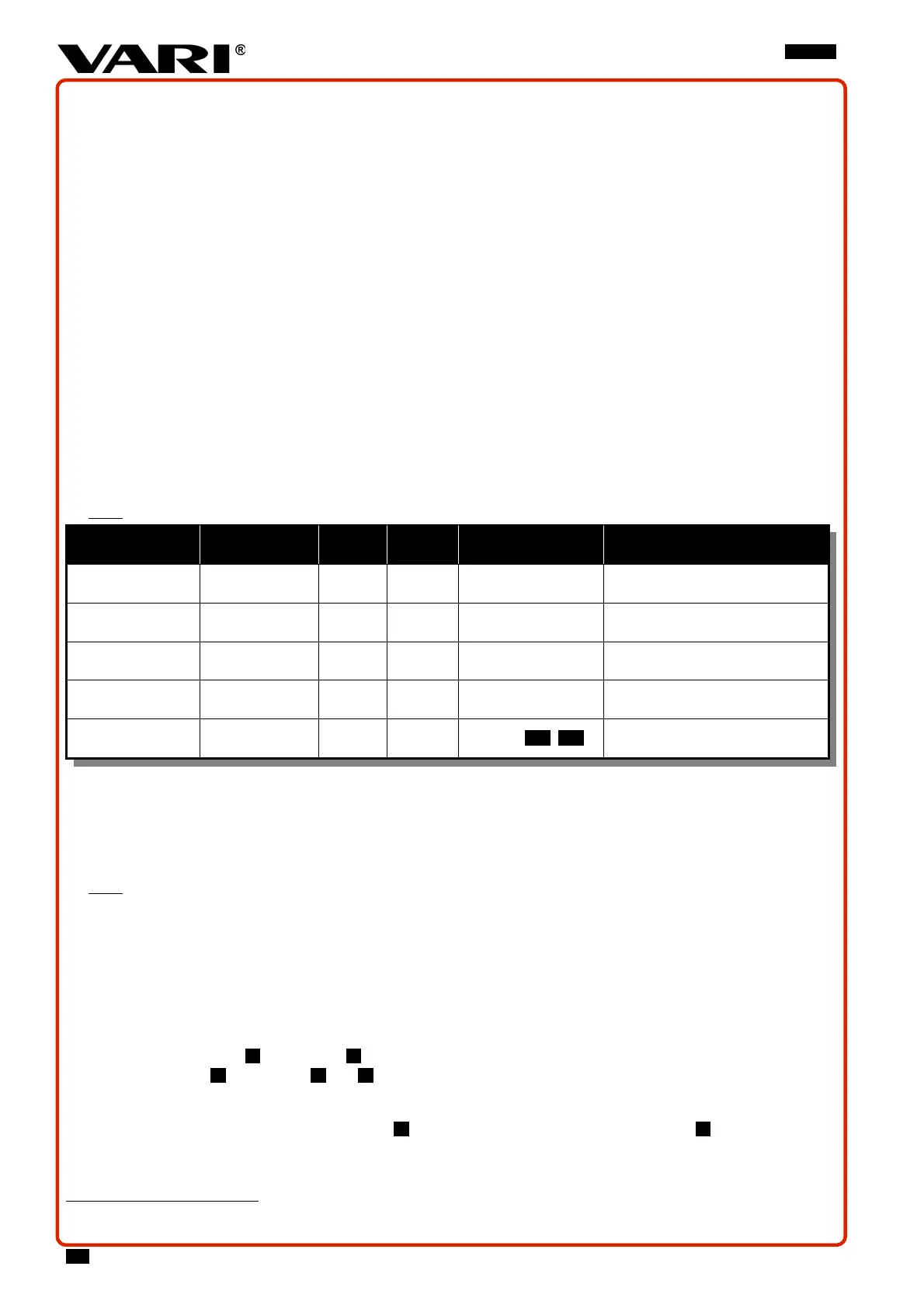

)

When using graphite grease, the seasonal lubrication intervals can be extended up to MP.

"-_

&"-

%%

.

" "

Bowden cables /

levers

min 2x

(5 drops)

yes oil

"!LM

Cable entrance into cable housing /

pins.

Disc drive pulley

casing

every 10 hours

(2 drops)

yes oil/grease

"!LO

Wheel drive clutch

pulley

every 10 hours

(2 drops)

yes oil/grease

"!LP

Contact area with frame.

Cam

every 5 hours

(2 drops)

yes oil

"!LN

Bolted connections yes grease

"!LR

^L

,

^S

Handlebars and side screen

attachment.

0!Y)"%

3.5.3 WORK BLADES SERVICE AND EXCHANGE

&""1%"---%%%!

If the work blades are deteriorated or damaged and causing cutter vibrations, it is necessary to renew or exchange

93

the blades.

)

he manufacturer bears no responsibility for damages caused by/on the cutter in case of a botched-up blades repair or when

original parts are not used. A sign identifying the manufacturer is imprinted in the blade and it is used as a proof of a genuine part.

0""&.a-"&-&&.-&%%&h

""%&!

1-"%&%&!0"%&-!"1&

%!

0..&&.--%"%..@

1) Hold the upper disc so that it does not spin and use tubular wrench n.16 to dismount the bolted connection of the blade

"!LV

.

First unscrew the M, than the % N.

2) Take the %&L and its parts ( N and O) out of the cutting disc. Align the blades and sharpen them. The blade slope should

hold 30° angle with the bottom blade level.

3) Check all blade parts for visible marks of damage. In case of damage, exchange the part with a new one.

4) Tighten the blade seating back. Tighten the % N firmly

94

. Secure the bolt from loosening with a M.

*..%&&&&&1a"%%"&"%&@

WM

Tyre pressure lower than minimum damages the tyre construction and shortens its life.

WN

The blades are double-sided; they can be turned around if necessary. The blades must never be damaged.

WO

Insufficient bolt tightening usually destroys the hardened washer around which the blades spin.

OR

Q#RSMRML

Loading...

Loading...