© by N&W GLOBAL VENDING S.p.A. 23 02-2014 4535 00

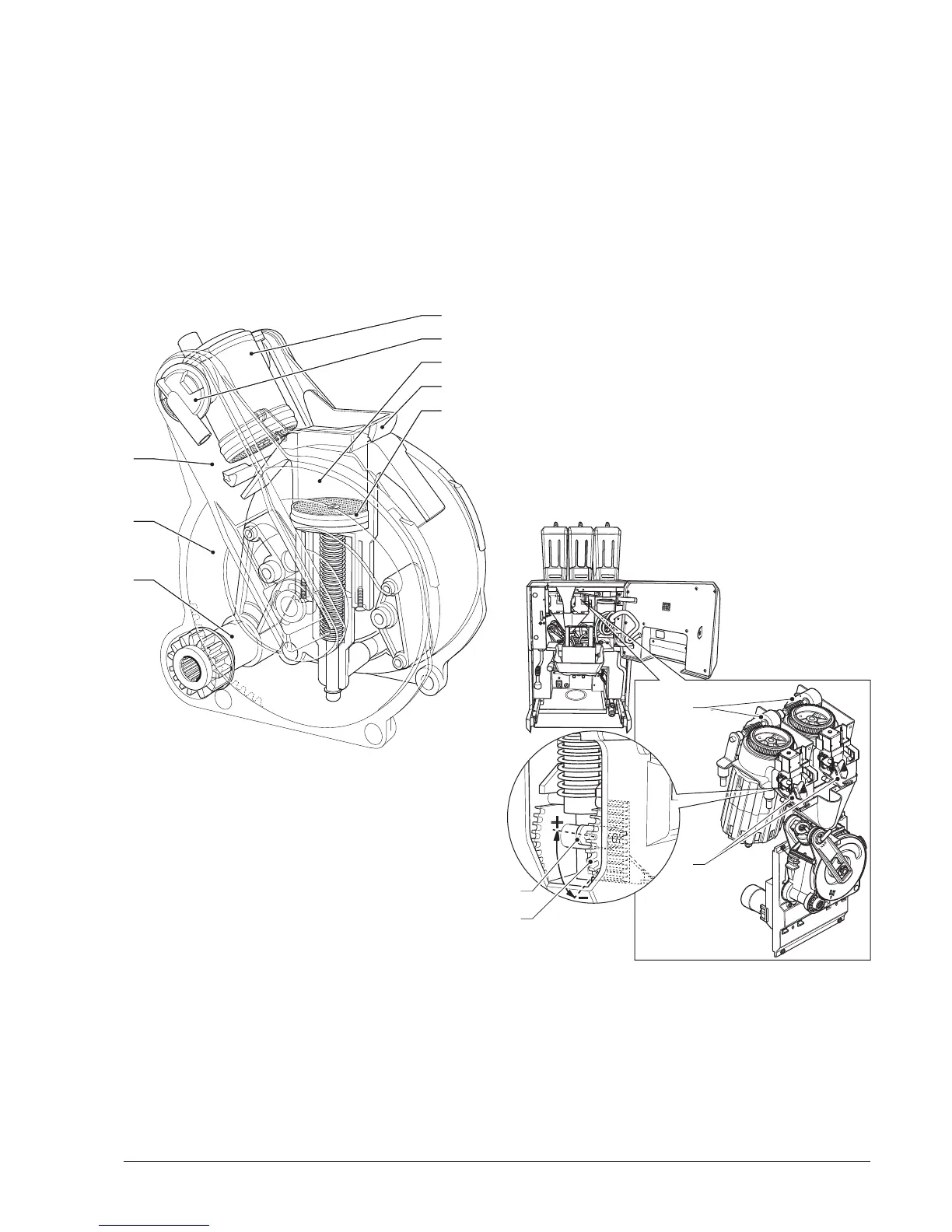

At the end of the coee dispensing phase, the upper

piston goes down in order to mechanically squeeze the

coee pod, facilitating the expulsion of excess water

through the 3rd route of the dispensing solenoid valve.

At the end of the cycle the gear motor is activated in the

opposite direction, lifting the upper piston and rotating

the infusion chamber towards the emptying side, on the

opposite side of the dispensing side; the lower piston

rises.

Once the emptying position is reached, the gear motor

inverts its rotation direction again, bringing the infusion

chamber back to the idle position.

The scraper holds the coee pod and lets it fall, while

the lower piston returns to the idle position.

8

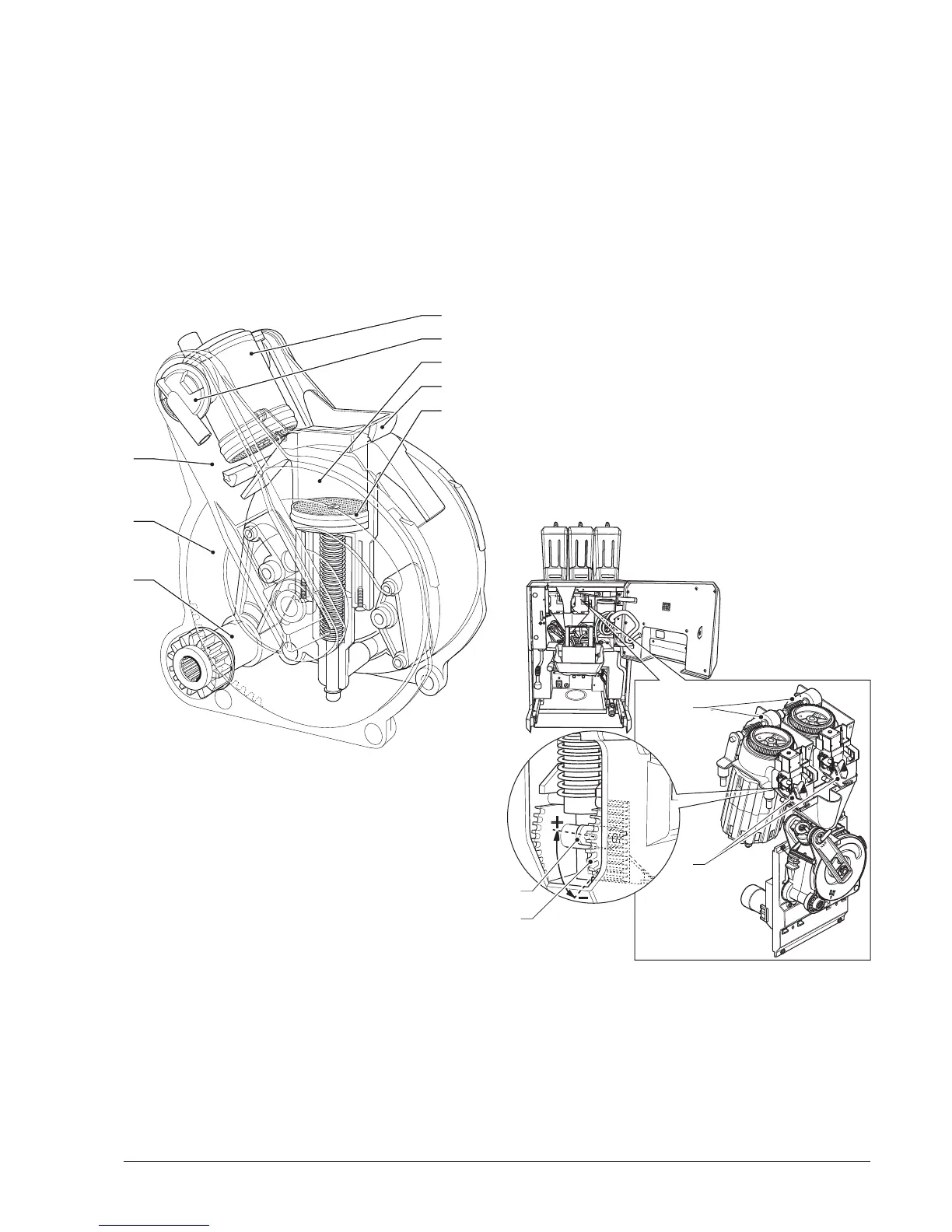

The coee unit can operate with coee doses between 7

and 13,5 gr.

The upper piston positions itself automatically according

to the programmed pressure.

A coee dose is composed of two quantities of ground

coee, released consecutively from the doser.

The doser can be set to dispense two dierent quantities

of ground coee;

- a first quantity, volume-dosed (more precise), is re-

leased upon the filling of the doser chamber;

- the second quantity, time-dosed, adjustable in percent-

age (from 1 to 99%) of the volumetric amount grinding

time, is released when the set time is achieved.

If the percentage is set to 0 only one release is carried

out;

if the percentage is set to 100 two volume-dosed re-

leases are carried out (filling of the chamber also for the

second release).

The chamber volume of the variable-dose doser can be

adjusted between 5.5 and 8.5 g using the adjustment

lever.

The dose adjustment lever can be positioned on one of

the 10 reference notches, taking into consideration that:

- raising the lever increases the dose:

- lowering the lever decreases the dose:

- each notch changes the dose by approx. 0.35 g.

3

4

1

2

Fig. 24

1- Blade-adjustment engine

2- Dosers

3- Dose adjustment lever

4- Dose adjustment

Loading...

Loading...