© by N&W GLOBAL VENDING S.p.A. 42 02-2014 4535 00

Chapter 3

Maintenance

The integrity of the machine and compliance of the

corresponding systems with the regulations shall

-

sonnel.

maintenance operations which require the disas-

sembling of components.

The operations described below shall be carried

the operation of the machine both from the point of

view of electrical safety and of hygiene.

In the event of maintenance and/or repairs, the vending

machine can be accessed from all sides; the possibility

should therefore be envisaged of rotating the machine

so that the back and side panels can be removed.

GENERALITIES

In order to ensure its correct operation, the machine

shall be subject to periodical maintenance.

Listed below are the operations to be carried out and

the related expiry dates; they are, obviously, indicative

because they depend on the conditions of use (i.e. water

hardness, environment humidity and temperature, type

of product used, etc.).

The operations described in this chapter do not include

all the maintenance interventions.

More complex interventions (i.e. descaling of the boiler)

shall be carried out by an engineer with specic knowl-

edge of the vending machine.

In order to avoid risks of oxidation or of chemical aggres-

sions in general, the painted surfaces and the surfaces

in stainless steel need to be kept cleaned by using neu-

tral detergents (avoid solvents).

Jets of water are to be absolutely avoided for wash-

ing the machine.

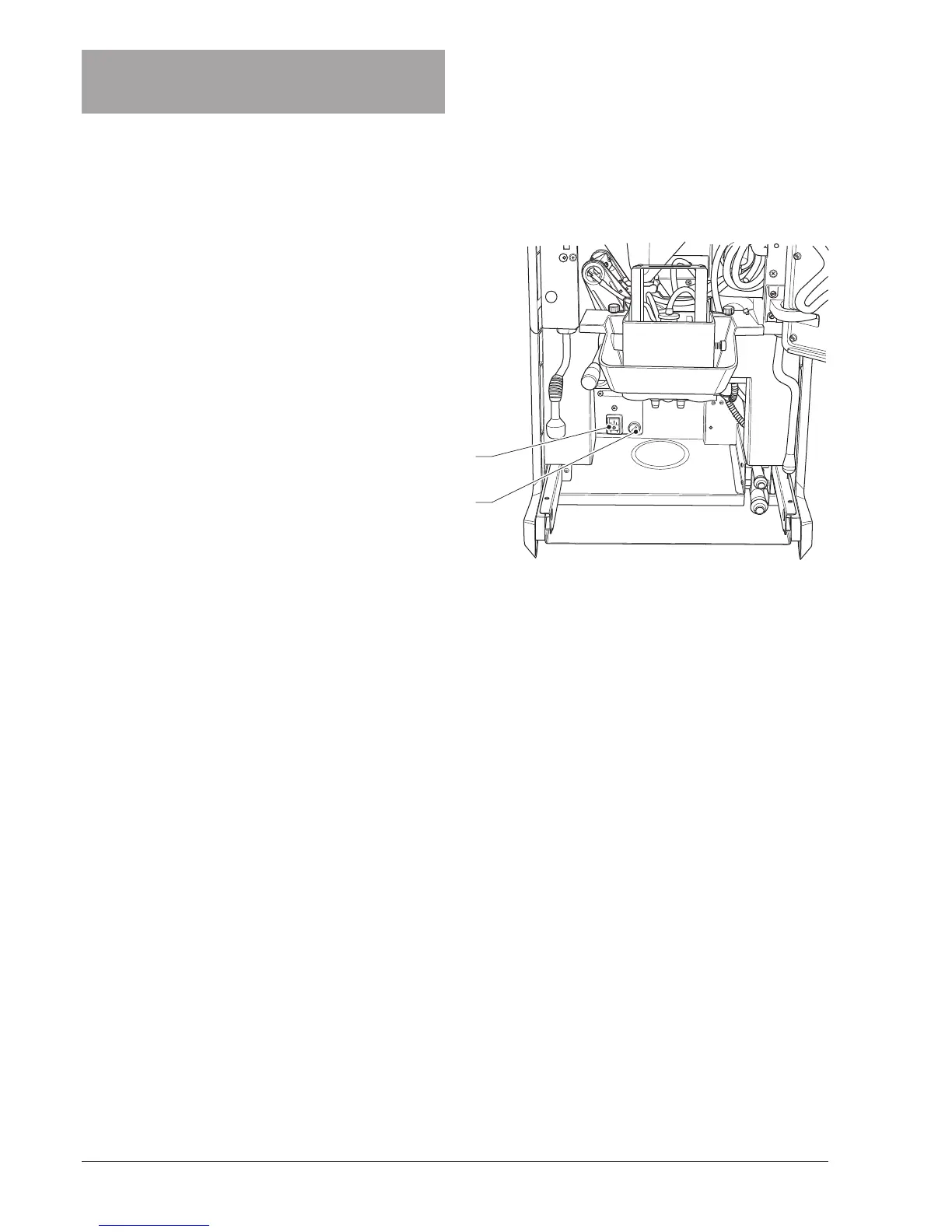

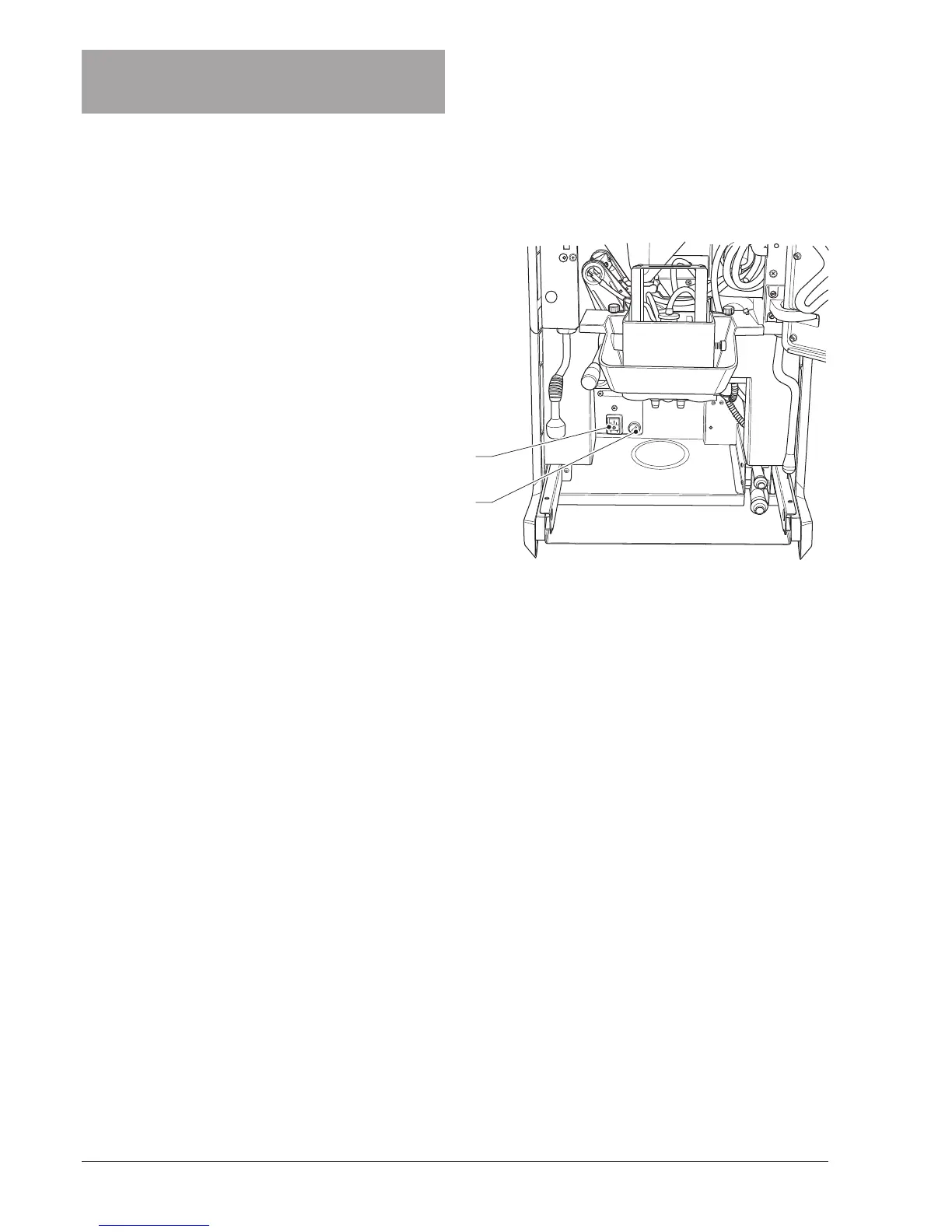

MAIN SWITCH AND FUSES

The main switch and fuse are accessible by removing

the solid and liquid residue containers

Important!

The protective covers need to be removed after dis-

connecting the machine from the power supply.

2

1

Fig. 25

1- Main switch

2- Line fuse

Loading...

Loading...