2.4 Air-distribution Considerations for Upflow Units

Various configurations are available:

• Front return

• Rear return

• Bottom return(not available onCW106 and CW114 models)

For in-room applications with supply and returngrilles, several feet of clearance must be maintained at the intake and

discharge of the unit.

Upflow rear-returnconfigurations use a filter box attached to the back of the unit. Allow25in. (635mm) onone side of the

unit for access to the rear-returnfilter box. Refer to the rear-return installationsheet, inside the rear-returnfilter box

package.

For ducted applications, duct flanges are supplied onthe blower outlets. Followthe SMACNA-Duct Construction Standard

for single-, dual-, or triple-blower systems. Do not runduct work off the perimeter flange onthe top of the unit. Thisflange is

for positioning and attaching the optional air discharge plenum withgrille. Attaching a duct to this flange may reduce

airflow to inadequate levels.

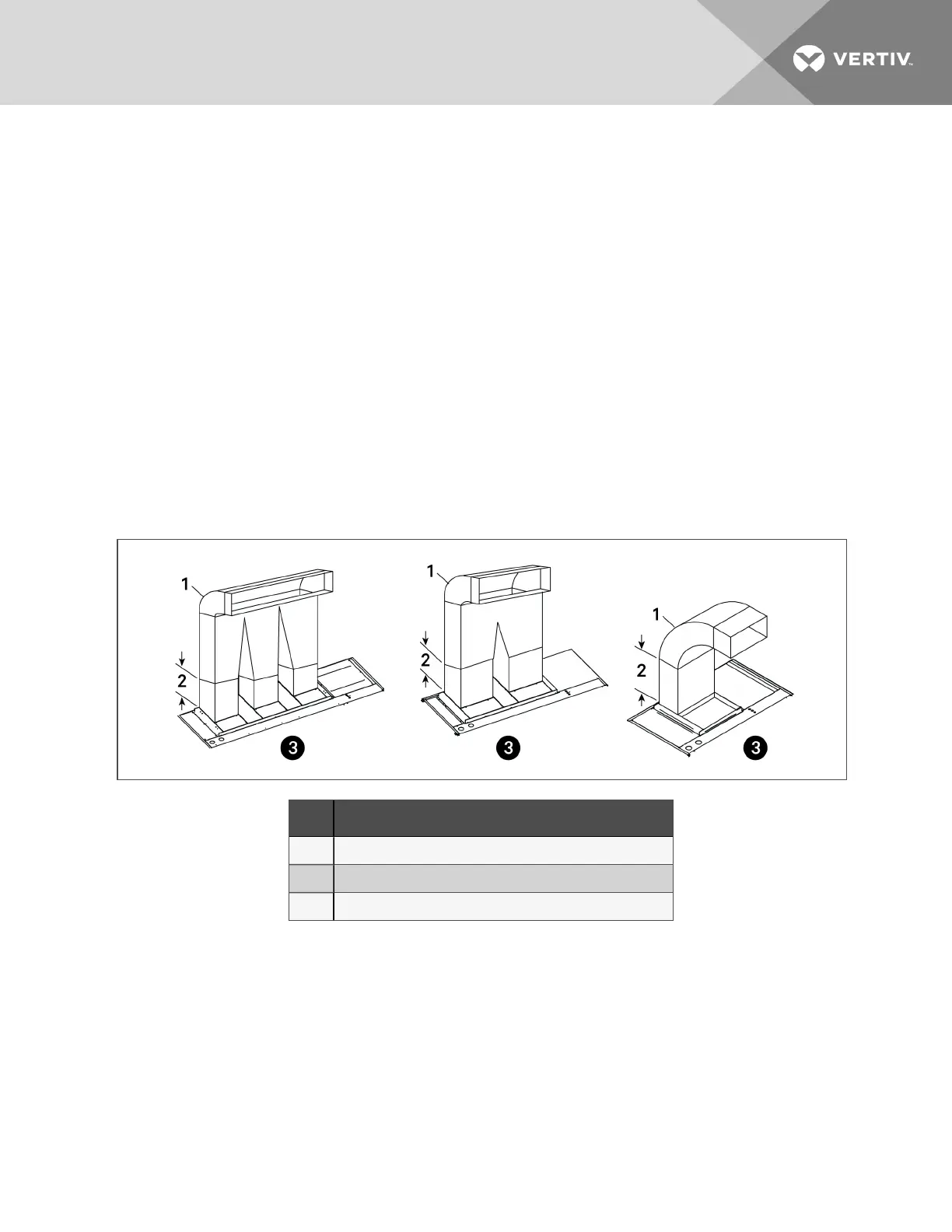

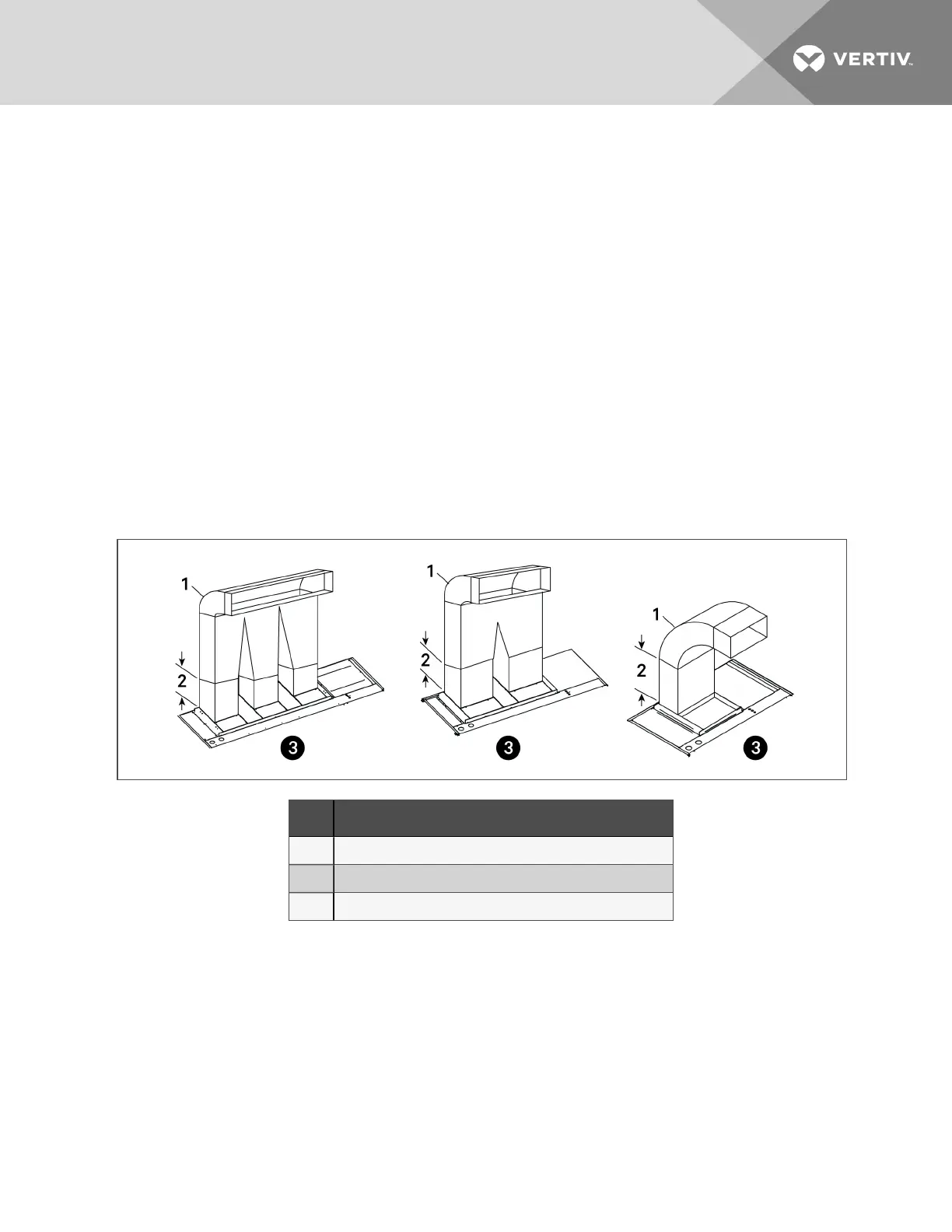

Figure 3.2 Upflow ducting configurations (forward-curved blowers)

Item Description

1 Typical ducting

2 Straightsectionsmustbe 1.5 to2.5 timesthe longest blowerdimension.

3 Front of unit

NOTE: Drain traps are qualified to a return duct static of negative 1.5 i.w.g. (-1.5i.w.g).

2Pre-installation PreparationandGuidelines

19

Loading...

Loading...