• The DA125 through DA250 are used with a Liebert® MCV heat rejection skid with receiver tanks. For these

systems, the outlet of the receivers on the outdoor Liebert® MCV heat rejection skid must be higher than the

elevation of the electronic expansion valves (EEV0 inside of the indoor unit. If the vertical height of the receiver

outlet is greater than 60 ft. (18.3m) above the EEV, consult the factory. Refer to DPN003965 in Submittal

Drawings.

• The DA265 is used with a Liebert® MCV heat rejection skid without receiver tanks. For these systems, the bottom

of the condenser coil on the outdoor Liebert® MCV heat rejection skid must be higher than the elevation of the

EEVs inside of the indoor unit. If the vertical height between the condenser coil and the EEV is greater than 60 ft.

(18.3m), consult the factory. Refer to DPN005207 in Submittal Drawings.

• The XDM200/400 is used with a Liebert® MCV heat rejection skid without receiver tanks. For these systems, the

bottom of the condenser coil on the outdoor Liebert® MCV heat rejection skid must be higher than the elevation

of the EEVs inside of the indoor unit. If the vertical height between the condenser coil and the EEV is greater

than 60 ft. (18.3m), consult the factory. Refer to DPN005138 in Submittal Drawings on page71.

• Install traps on hot gas (discharge) lines at the base of the vertical risers over 5 ft. (1.5m) and then for vertical

risers over 25 ft. (7.6m). Install a trap in 20 ft. (6m) increments or evenly divided over the vertical rise. The DA250

and DA265 each have piping out of the top of the unit with internally installed traps on the hot gas lines.

• Consult factory for piping lengths exceeding the lengths in Table 5.5 below.

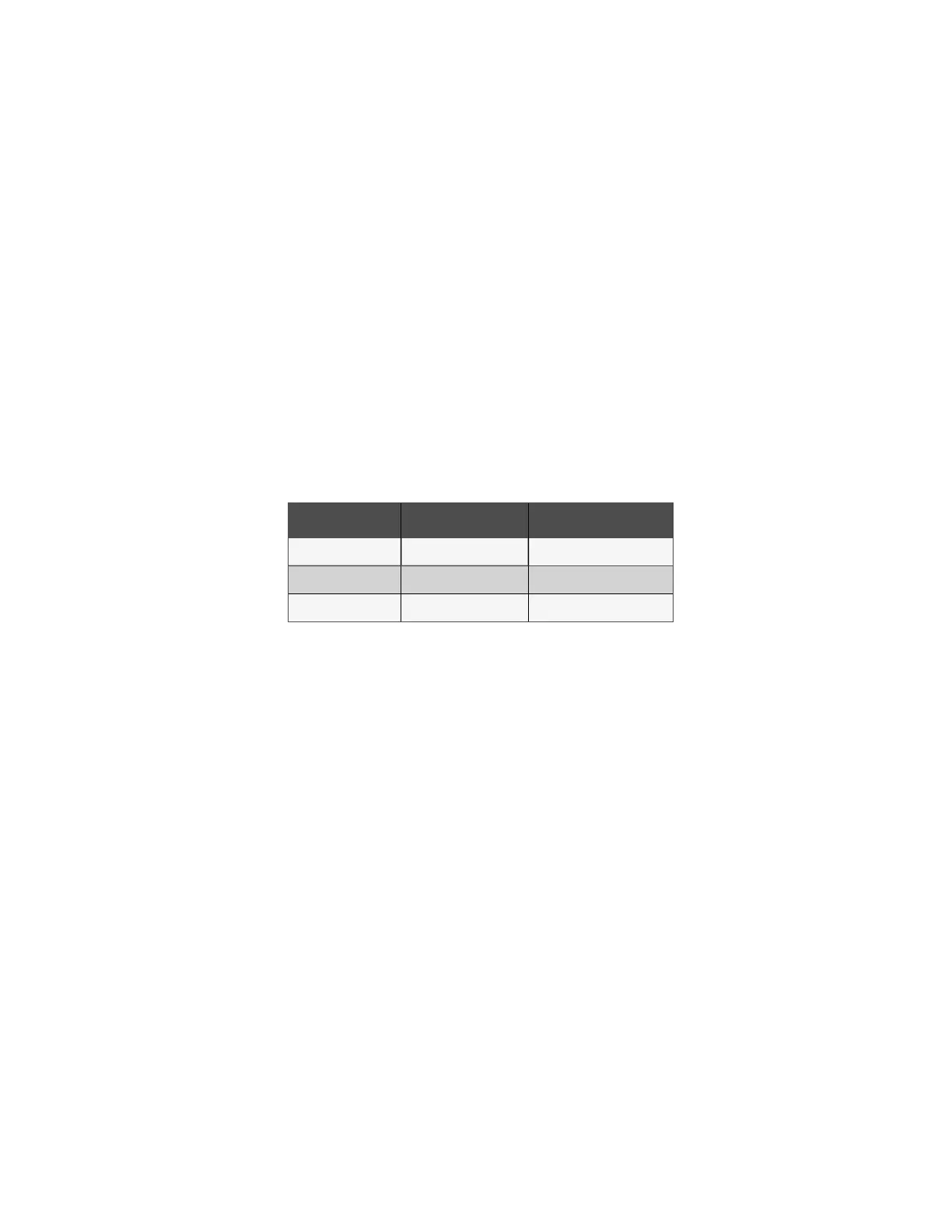

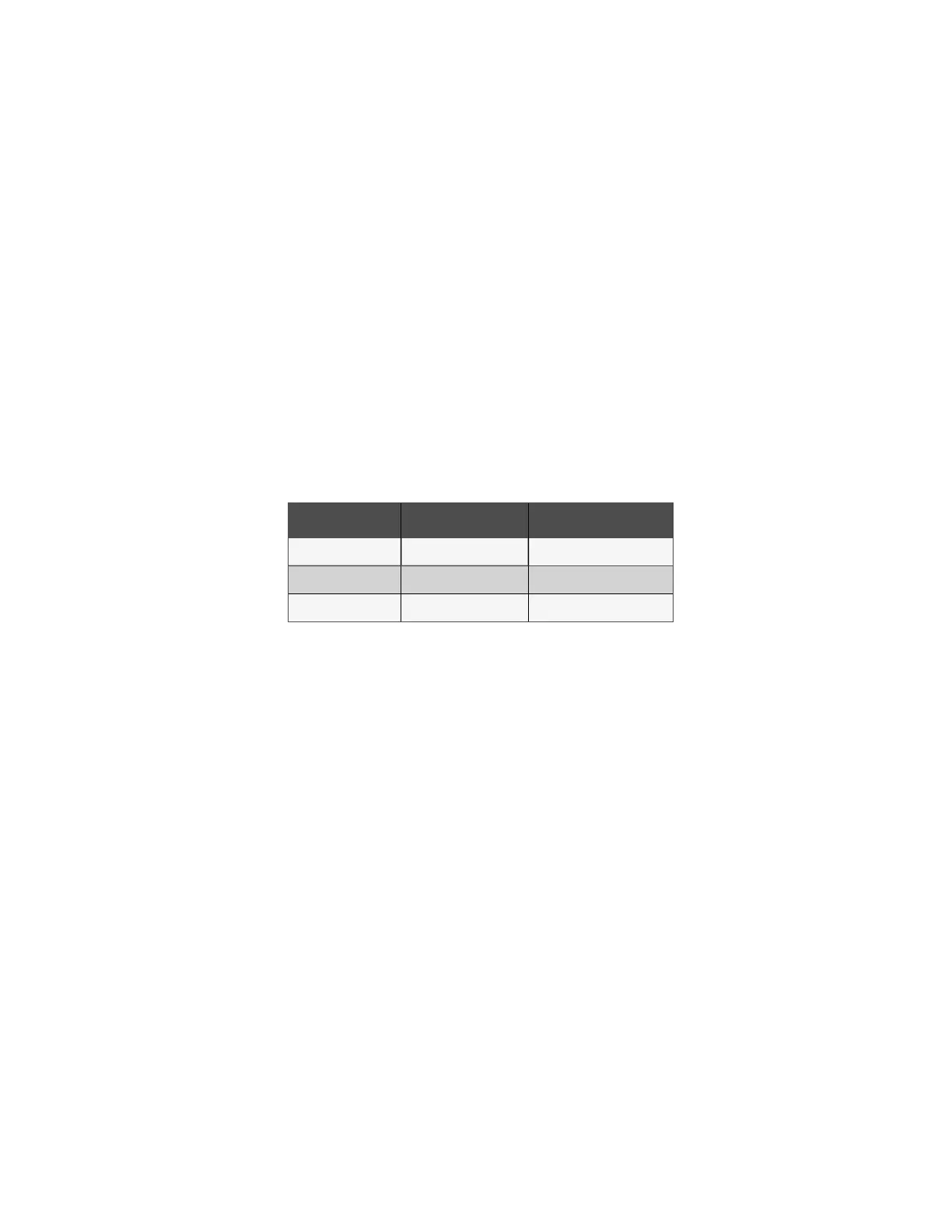

Indoor Unit Maximum Actual Length Maximum Equivalent Length

DA250, DA265 200 ft. (61m) 300 ft. (91m)

DA125, DA150, DA165 300 ft. (91m) 450ft. (137.2m)

XDM200/400 300 ft. (91m) 450ft. (137.2m)

Table 5.5 Piping Lengths

• Pitch horizontal hot gas piping down at a minimum rate of 1/2in.per 10ft. (42mm per 10m) so that gravity will

aid in moving oil in the direction of refrigerant/oil flow.

• Keep piping clean and dry, especially on units with R-410A refrigerant.

• Avoid piping runs through noise sensitive areas.

• Do not run piping directly in front of discharge air stream.

• Refrigerant oil – do not mix oil types. Consult the indoor-unit installation/user guide for refrigerant type and oil

requirements.

Refer to ASHRAE Refrigeration Handbook for general, good practice refrigeration piping. The indoor cooling unit has a factory

installed high pressure safety switch in the high side refrigerant circuit. A fusible plug is installed in each Vertiv™ Liebert® DSE

receiver.

NOTE: Liebert® DSE and Liebert® XDM systems require all indoor refrigerant piping to be insulated 1/2 in. minimum.

All outdoor field refrigeration piping does not need to be insulated. The installing contractor is responsible for the insulating,

securing, protecting, and the proper installation of all field refrigerant piping, observing the details outlined by the Engineer of

Record.

5 Piping Proprietary and Confidential ©2024 Vertiv Group Corp. 19

Vertiv™ Liebert® MCV Installer/User Guide

Loading...

Loading...