4.5 Accessories container

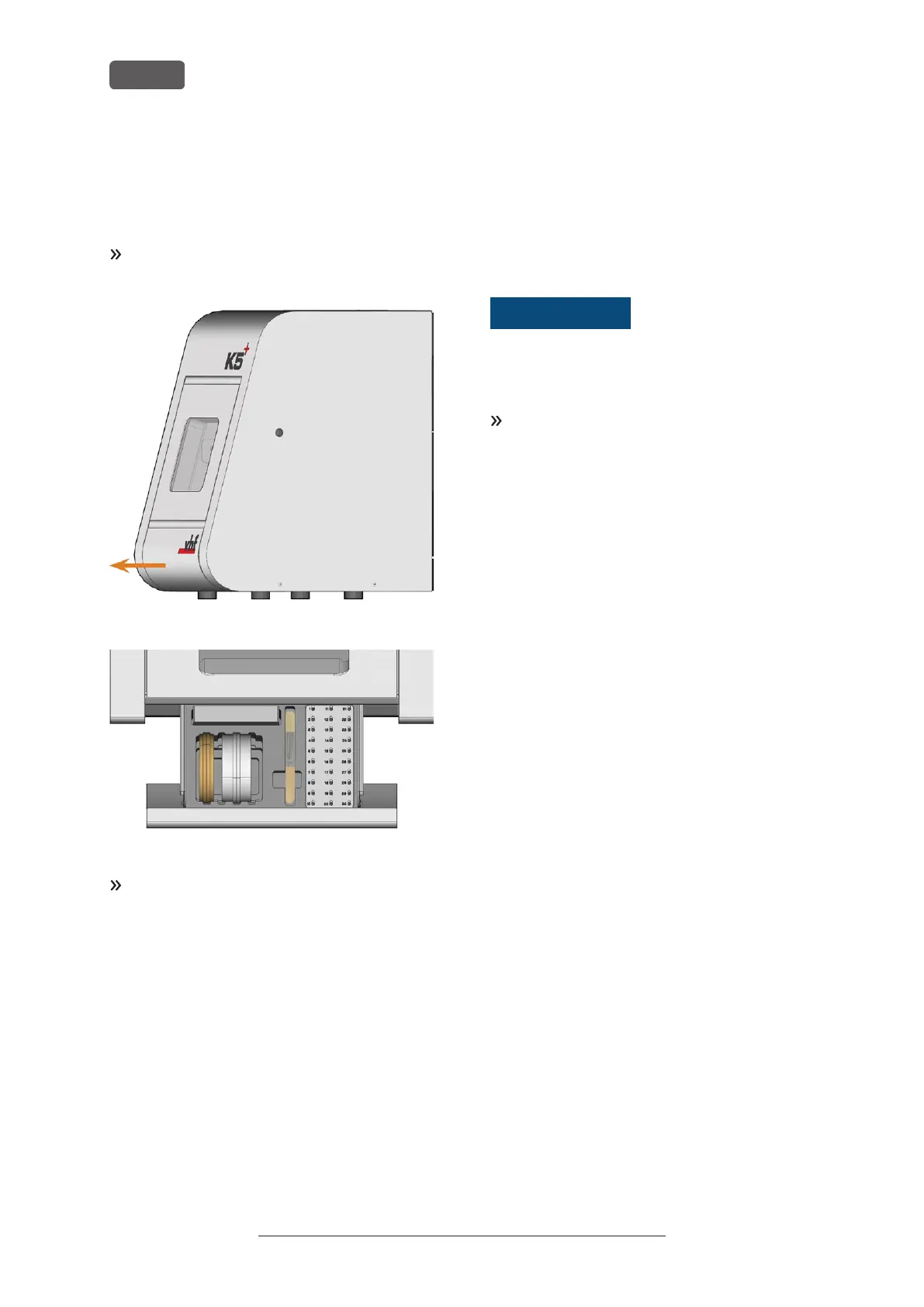

In the accessories container below the working

chamber, you can store blanks, tools, and the spindle

service set ready to hand.

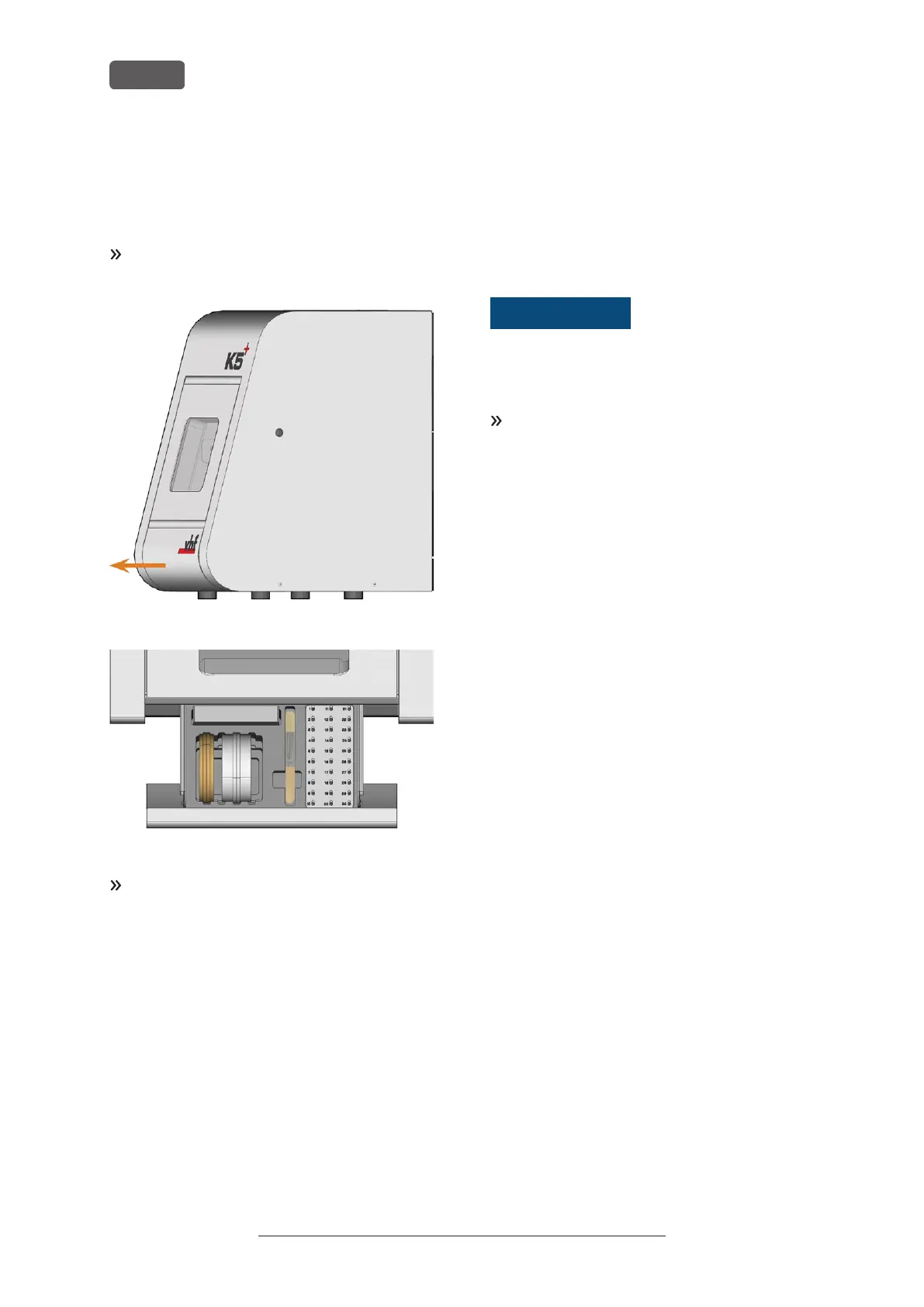

To access the accessories container, manually pull it

out of the machine.

FIG. 5 OPENING THE ACCESSORIES CONTAINER

FIG. 6 ACCESSORIES CONTAINER (BLANKS AND TOOLS NOT PROVIDED)

To close the accessories container, push it into the

machine until it is completely closed.

4.6 Anti-soiling concept

The anti-soling concept decreases the soiling and wear

of sensitive machine parts.

The anti-soiling concept does not replace the regular

cleaning of the machine. Without regular cleaning, the

machine life decreases significantly.

NOTICE

Machine damage when dry

machining without an air

extraction system

When dry machining, an operational external air extrac-

tion system must be installed. Otherwise, the machine

will get soiled over time and become defective.

Always use a correctly installed and operational

external air extraction system during dry machining.

The anti-soiling concept consists of:

n

The external air extraction system ‒ An

external suction unit creates a vacuum in the work-

ing chamber and extracts machining debris from

it.

n

Air that is emitted into the working cham-

ber ‒ Blows machining debris away from the

spindle and other machine parts.

n

The internal vacuum sensor ‒ Constantly

monitors the vacuum in the working chamber.

n

The ionizer ‒ The ionizer electrically discharges

machining debris of certain materials to reduce

their distribution in the working chamber.

4.7 CAM computer

To operate the machine, you must use a computer

running Windows

®

(“CAM computer”) and specially

designed software (“manufacturing software”). The

manufacturing software consists of the following

components:

n

DENTALCAM ‒ A CAM application for creating

and calculating virtual blanks (“jobs”).

n

DENTALCNC ‒ A CNC application for machining

jobs and maintaining the machine.

To create and design the dental objects you also need

a CAD application (sold separately by specialist

dealers).

Original Operating Instructions:K5+

Version: 12/16/2021

K5+ – Machine overview

EN 12

Loading...

Loading...