6.4.3 Mounting the block holder in the work-

ing chamber

1. Open the working chamber door.

2. Open the blank holder.

3. Remove the blank from the blank holder if any.

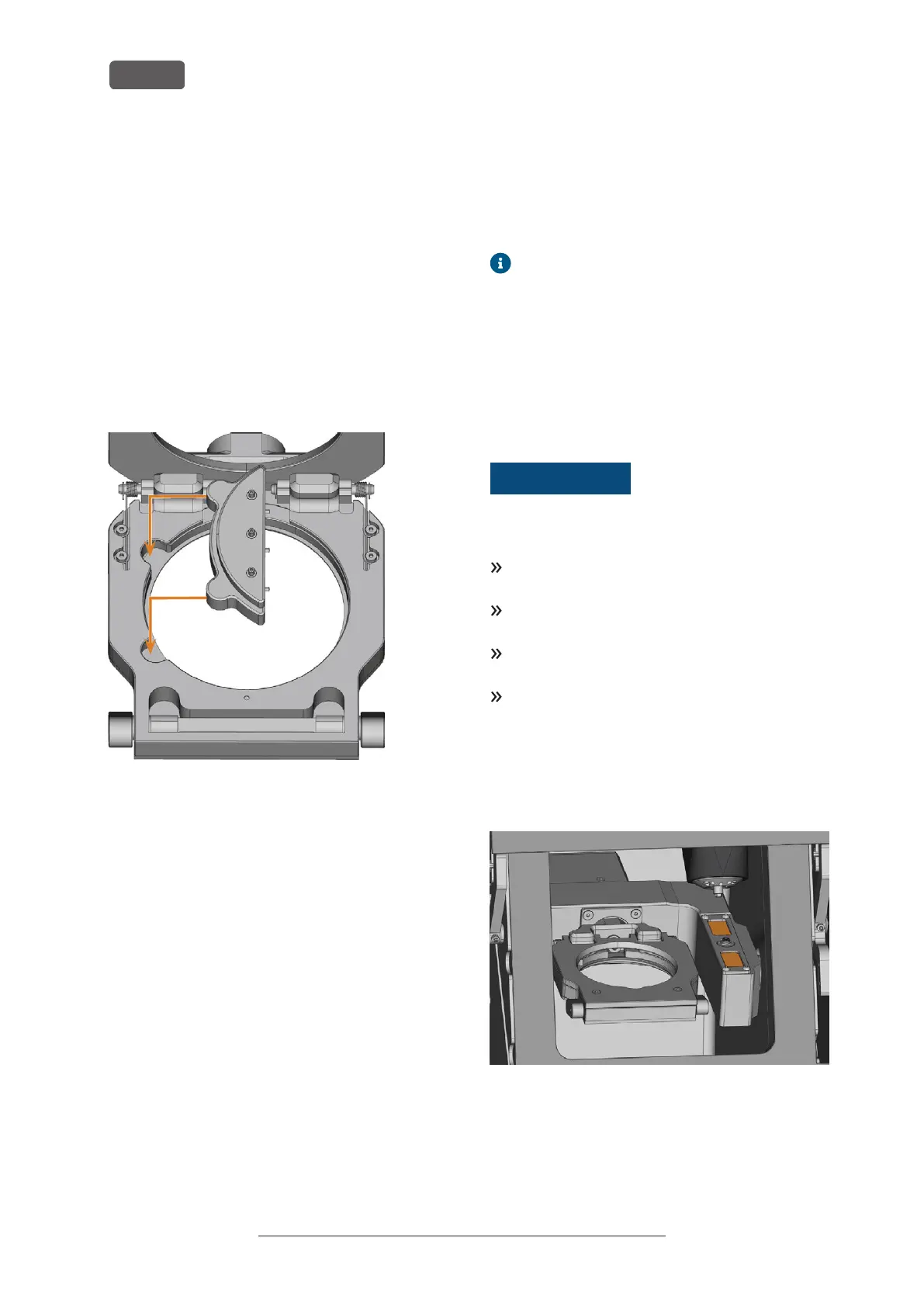

4. Correctly orient the block holder:

n

The fixing screws must face upwards.

n

The positioning aids must be positioned on

the left side.

5. Insert the block holder into the blank holder and

hold it in place with one hand from below.

FIG. 42 INSERTING THE BLOCK HOLDER INTO THE BLANK HOLDER

6. Close the blank holder with the other hand.

6.4.4 Using an optional abutment holder

With an optional abutment holder, your machine can

process prefabricated abutments with prefabricated

connection geometries.

Abutment holders for common abutment

systems can be obtained from customer

service.

You can find more information about abutment

holders and abutment blanks at the following internet

address:

dentalportal.info/abutments

6.5 Managing tools

NOTICE

Damaging of the spindle or

the tool positions if you use

improper tools

Improper tools can damage the collet chuck of the

spindle and / or the tool positions.

Only use tools with a sufficiently large chamfer at the

tool shank.

Install a retaining ring as a stop ring according to

DIN 471-A3.

Only insert tools with a maximum diameter of 3mm

at the thickest part into the collet chuck.

Only insert tools with a maximum cutting edge dia-

meter of 2.6 mm into the tool magazine.

We recommend original tools as they are designed

especially for the designated jobs.

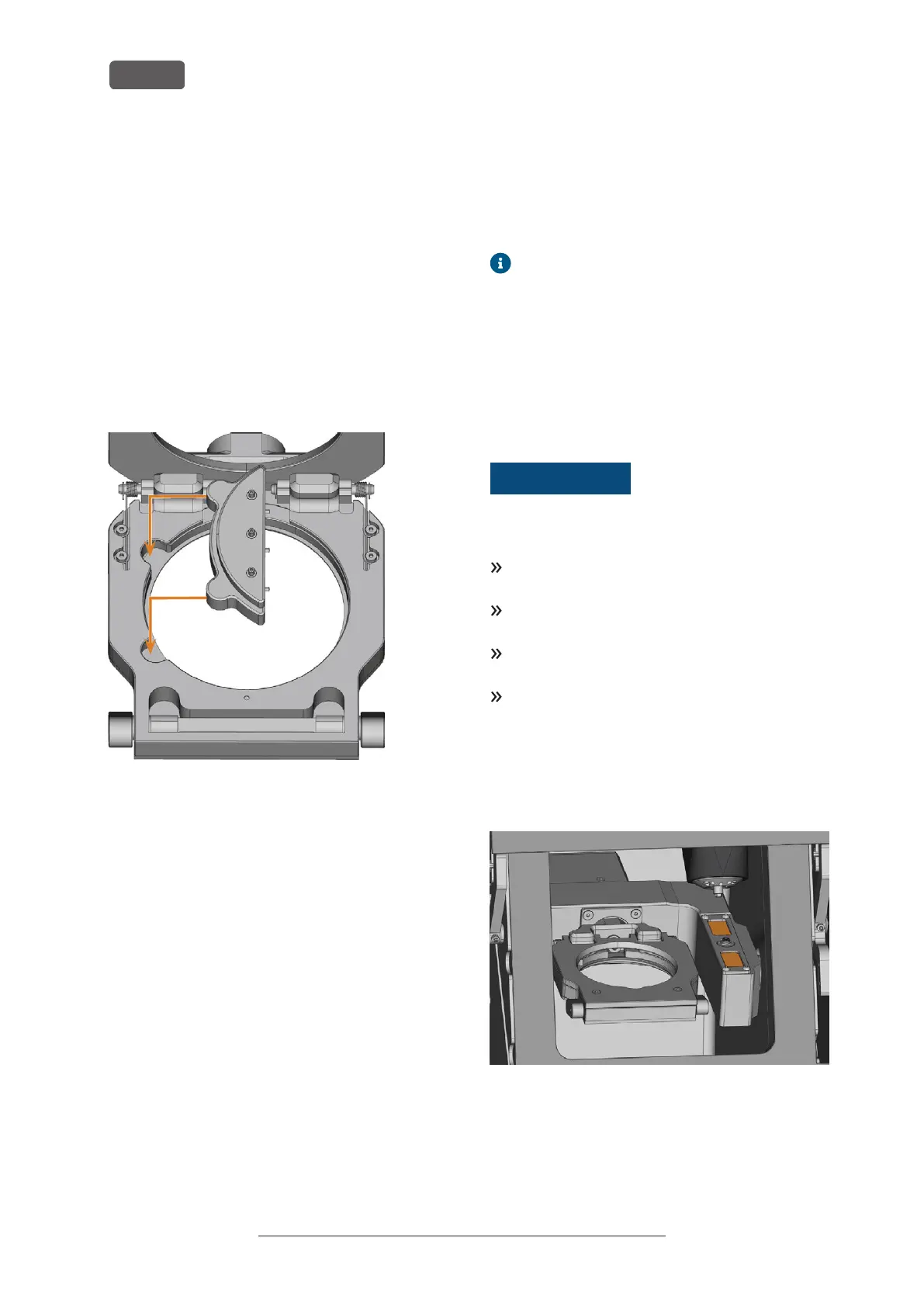

You can insert up to 16 tools into the tool magazine.

FIG. 43 TOOL MAGAZINE IN THE WORKING CHAMBER (MARKED ORANGE)

Normally, the machine loads tools from the tool

magazine of the machine. In the following cases, this is

not possible:

n

A tool magazine position is worn so that it can no

longer properly hold a tool

Original Operating Instructions:K5+

Version: 12/16/2021

K5+ – Operation: Preparing jobs

EN 34

Loading...

Loading...