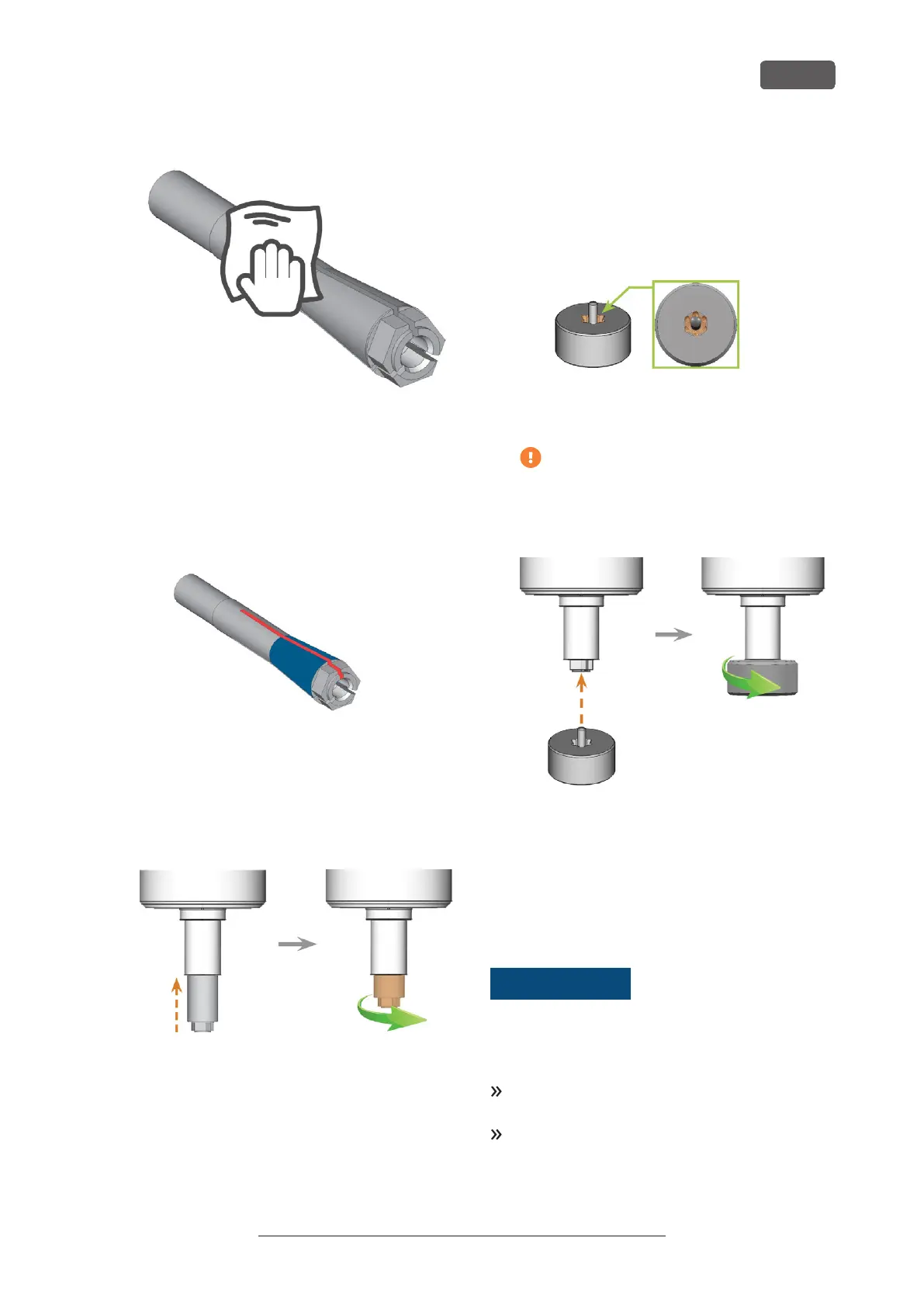

FIG. 58 CLEANING THE COMPLETE OUTER SURFACE OF THE COLLET

CHUCK WITH A CLOTH

13. Put a small amount of the collet grease on the index

finger and smear it with the thumb.

14. Apply the smeared collet grease to the flanks of the

collet chuck.

FIG. 59 GREASING THE COLLET CHUCK; SURFACE IN WHICH GREASE IS

TO BE APPLIED IS MARKED IN BLUE; SLOT THAT MAY NOT BE GREASED IS

MARKED IN RED

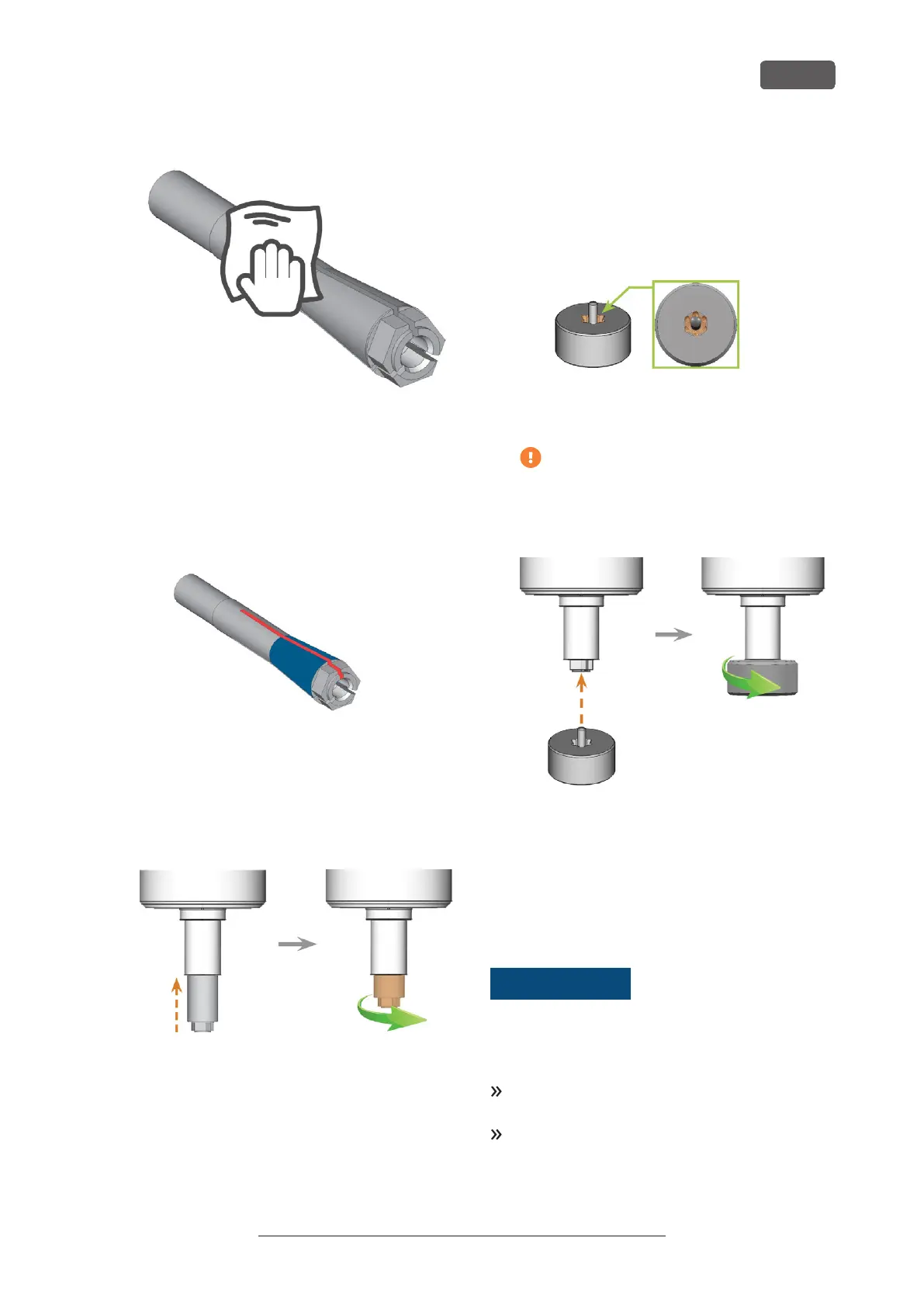

15. Insert the collet chuck into the spindle. Screw the

collet chuck in by twisting it counter-clockwise with

your hand.

FIG. 60 SCREWING IN THE COLLET CHUCK (MARKED ORANGE IN THE

RIGHT ILLUSTRATION) INTO THE SPINDLE WITH YOUR HAND

16. Insert the pin of the knurled nut into the collet

chuck. Ensure that the collet chuck is properly

seated in the recess of the knurled nut.

17. Tighten the collet chuck with the knurled nut:

a. Insert the pin of the knurled nut into the col-

let chuck.

b. Ensure that the collet chuck fully sits in the

recess of the knurled nut.

FIG. 61 RECESS IN KNURLED NUT (MARKED ORANGE)

c. Twist the knurled nut clockwise.

The collet chuck must be screwed in tightly.

Otherwise rotational imperfections can

occur during operation which will worsen

your processing results

FIG. 62 TIGHTENING THE COLLET CHUCK WITH THE KNURLED NUT;

RECESS IN KNURLED NUT MARKED ORANGE

18. Store the spindle service set in a safe place.

19. Close the working chamber door.

8.8 Checking the compressed air

regulator

NOTICE

Damaging of the machine

when compressed air is

contaminated

Compressed air that does not fulfill the guidelines for

purity according to ISO 8573-1 can damage the

machine.

Check the water separator of the compressed air reg-

ulator daily for contamination.

Never use the machine if there is water, oil or solid

particles in the water separator.

K5+ – Maintenance and do-it-yourself

EN 45

Original Operating Instructions:K5+

Version: 12/16/2021

Loading...

Loading...