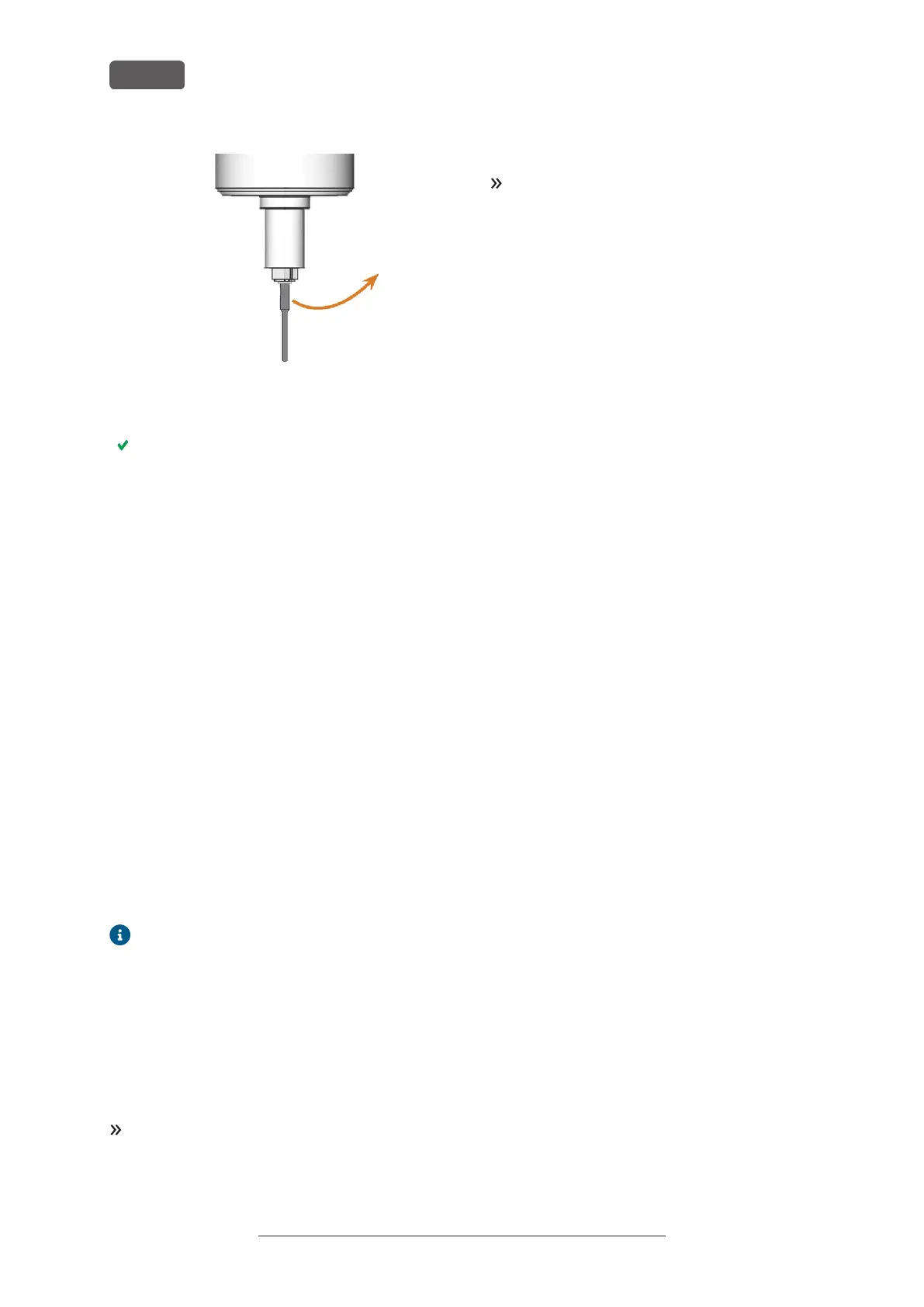

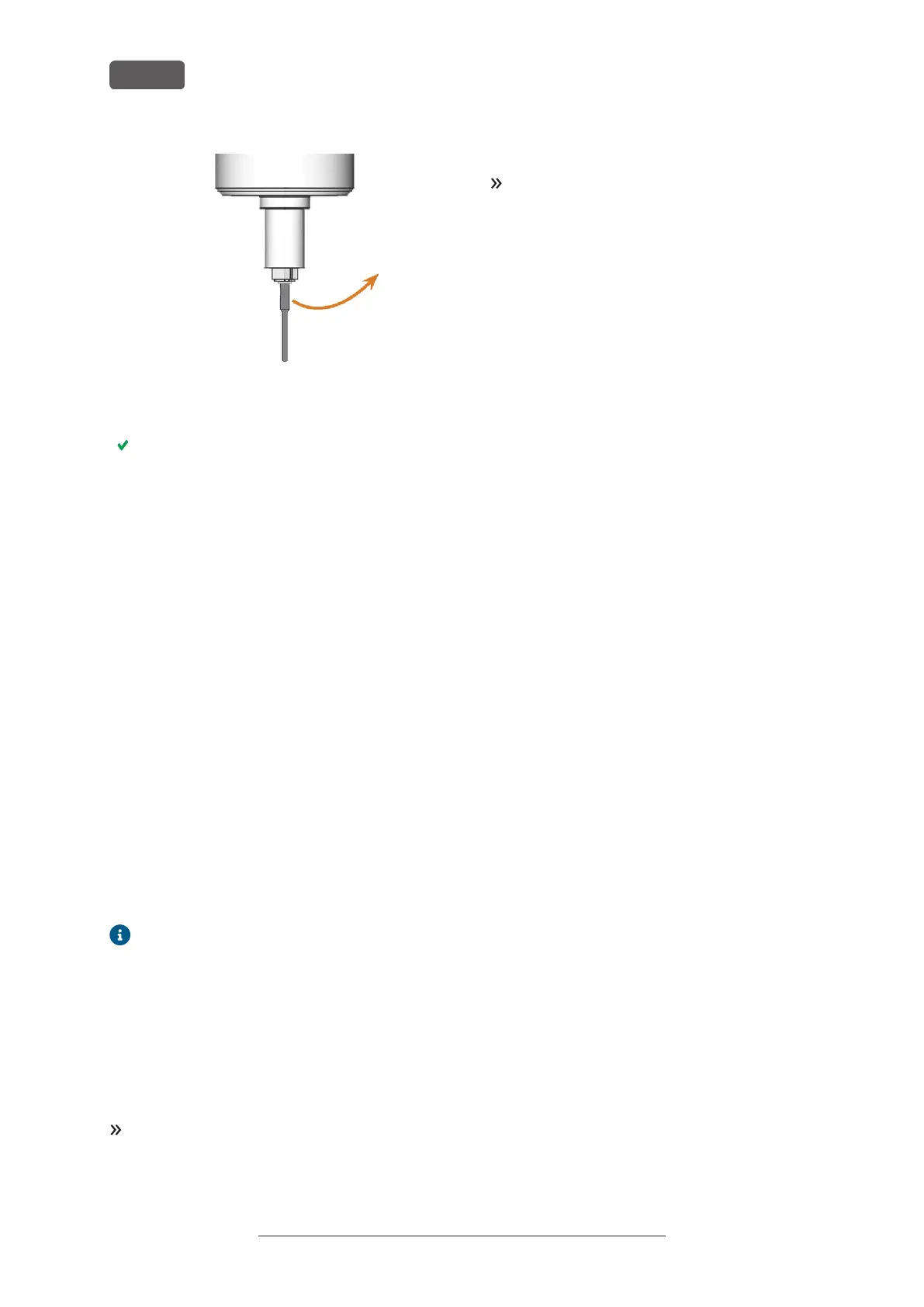

FIG. 46 REMOVING THE TOOL FROM THE COLLET CHUCK

9. Close the working chamber door.

10. Confirm the current message.

The following happens:

a. The collet chuck closes.

b. If your machine is equipped with an automatic

working chamber door, the door automatically

closes.

c. The spindle moves to its default position.

7.3 Job interruptions and job abor-

tions

A job will be interrupted in the following cases:

n

The compressed air supply is not sufficient

n

The vacuum in the working chamber is not suf-

ficient

An interrupted job will normally be continued auto-

matically after the error is corrected.

A job will be aborted in the following cases:

n

In case of a machine malfunction

n

In case of a tool breakage

n

In case of a power failure

If a job was aborted, you have to restart it.

DENTALCNC allows you to resume the job from

the last machining step. For more information,

see the corresponding documentation.

7.3.1 How to proceed in case of a job inter-

ruption

If the job was interrupted, DENTALCNC displays a

corresponding message.

If the compressed air is insufficient

Check the following:

n

The manometer of the compressed air regulator

n

The installation of the pneumatic hoses

n

Your compressor

If the vacuum is insufficient

Check the suction hose and your suction unit.

7.3.2 How to proceed in case of a machine

malfunction

A machine malfunction is recognized by the internal

control unit in case of a critical event. The working

chamber will be illuminated in red. DENTALCNC

displays the error message and error code that was

sent by the control unit.

1. Record the error message and error code that is dis-

played.

2. Restart the machine and the CAM computer. If the

problem persists, continue with the next step.

3. Disconnect the machine from the electrical source

and prevent it from being restarted.

4. Contact customer service. Have the error message

and error code readily available.

5. If you need to remove a blank from the working

chamber, perform an emergency opening of the

working chamber door.

7.3.3 How to proceed in case of a tool break-

age

If a tool breaks during machining, the machine will not

recognize this immediately. Instead, the spindle will

continue to move with the broken tool. The tool

breakage will be recognized upon the following

events:

n

The next regular tool change

A tool breakage can be caused by the following:

n

The tool was damaged or worn

n

The tool was put into the wrong tool position or

was manually inserted into the spindle at the

wrong time. As a consequence, it was not suitable

for the processing step.

n

The distribution of the objects in the blank (“nest-

ing”) was not correct.

If a tool breaks, do the following:

1. Open the working chamber door.

2. Remove all parts of the broken tool from the work-

ing chamber and the collet chuck.

3. Re-add the tool to the virtual ATB and virtual tool

magazine in DENTALCNC.

4. If the spindle picked up the tool from the tool

magazine, check if the tool was inserted into the

correct position. Insert a spare tool into the correct

position in the tool magazine.

5. If you manually inserted the tool into the collet

chuck, check if the broken tool corresponds to the

Original Operating Instructions:K5+

Version: 12/16/2021

K5+ – Operation: Executing jobs

EN 38

Loading...

Loading...