ВШПА.421412.304 И1 SCIENTIFIC-PRODUCTION ENTERPRISE VIBROBIT LLC

Sensor functionality test

Sensor test is carried out by I

sense

calculated value. Sensor is deemed functional, if value falls within acceptable

limits (CurrValidMin, CurrValidMax), setup during the module settings.

Monitoring of minimum/maximum acceptable sensor current can be disabled in the module settings

(EnaValidMin, EnaValidMax respectively). If sensor current monitoring is switched off at one of the limits, sensor

is deemed functional independent of calculated sensor current.

Enabling of sensor current monitoring can be useful, for example, during MK40 Module operation with sensor

signals level 0-5mA; in this case, disabling of sensor current lower limit monitoring is reasonable.

If I

sense

value is lower than minimum acceptable current level CurrValidMin, sensor signal level is deemed too

low (ErrorSenseLow, FlagError flags are activated). In order to normalize measuring channel function, I

sense

value must be higher than CurrValidMin + CurrValidHist (ErrorSenceLow flag is dropped).

If I

sense

value is higher than maximum acceptable current level CurrValidMax, sensor signal level is deemed

too high (ErrorSenseHigh, FlagError flags are activated). In order to normalize measuring channel function,

I

sense

value must be lower than CurrValidMin - CurrValidHist (ErrorSenceHigh flag is dropped).

When any abnormal sensor current level flag is activated (ErrorSenseLow, ErrorSenseHigh), measured

parameter value is taken as equal to zero.

It is not recommended to set sensor current level hysteresis value (CurrValidHist) equal to zero, as the

alarm frequent switch-over effect may occur.

After normalization of sensor function and ErrorSenseLow, ErrorSenseHigh flags are dropped, FlagError

flag is dropped after definite time interval TestPointSenseOK. After FlagError flag drop, calculated value of

measured parameter is compared with set-point.

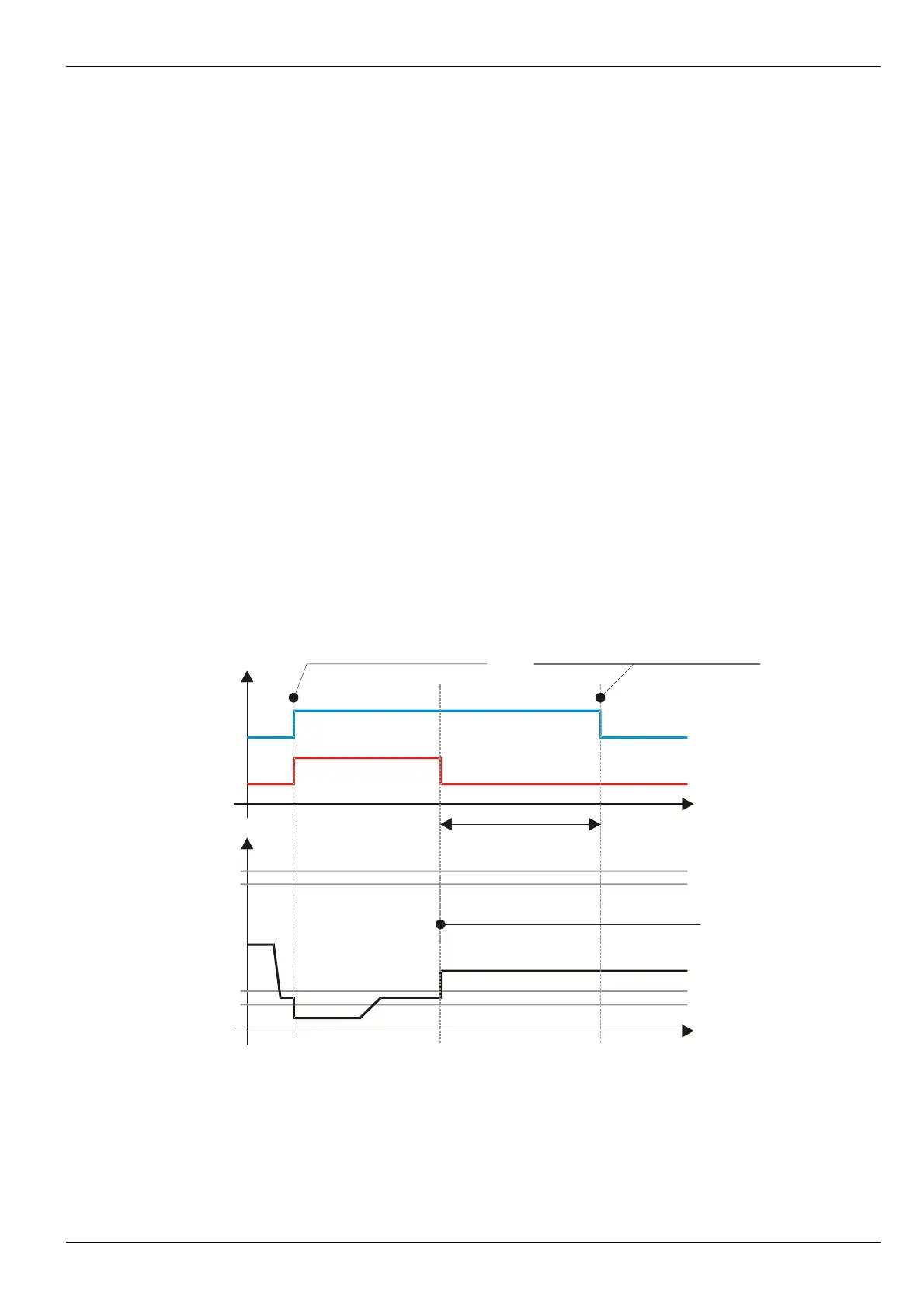

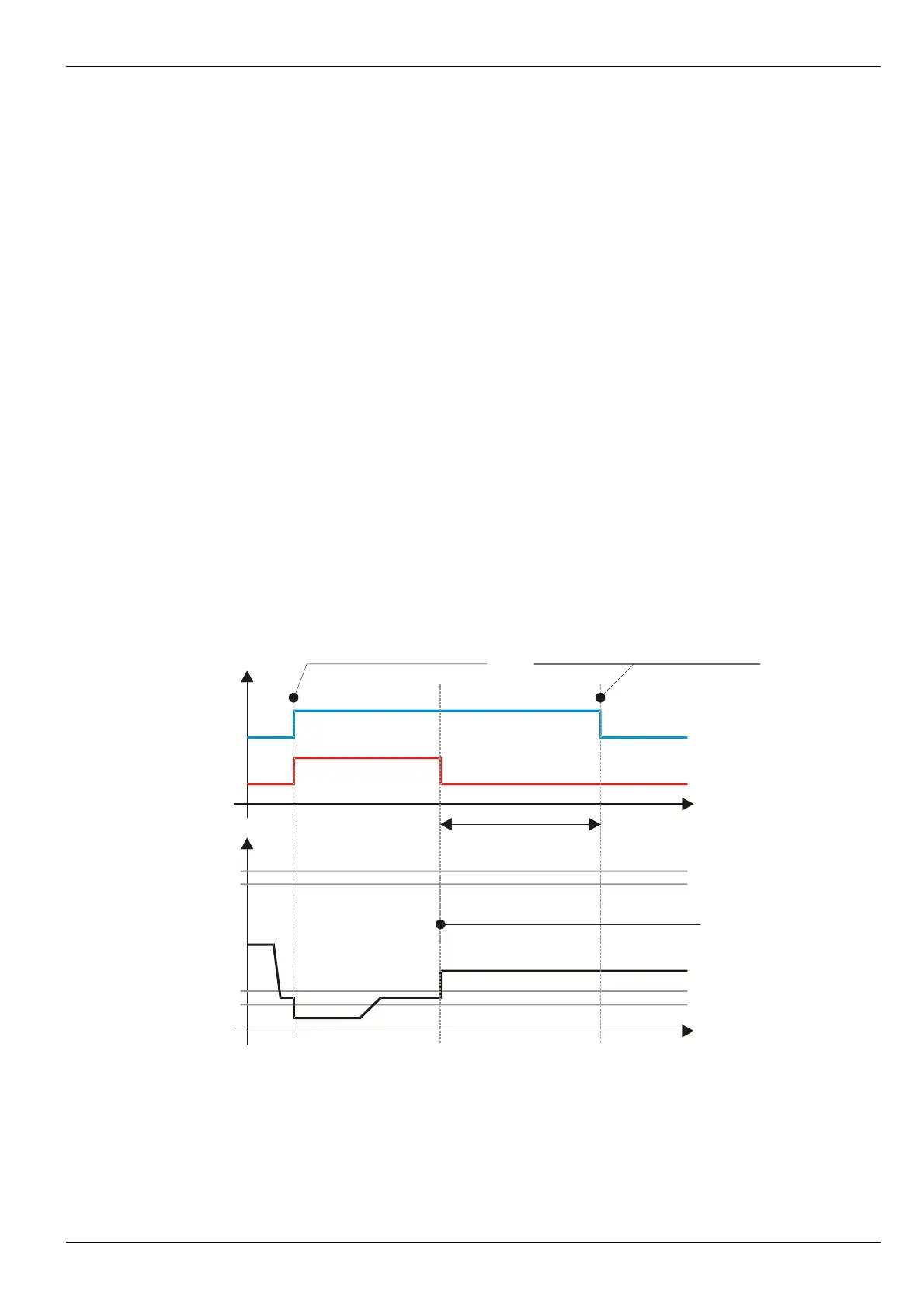

In Figure 3 is shown an example of sensor test algorithm during sensor constant current decrease below

acceptable level. Sensor current acceptable levels are equal to 0,9mA and 5,1mA respectively, hysteresis – 0,1mA.

Figure 3. Sensor test algorithm during sensor constant

current decrease below acceptable level

After the module resetting, sensor is deemed functional, however timeout is to be counted before comparing

parameter value with set-points value, as FlagError flag is automatically activated after resetting.

No revisions

13

ErrorSenseLow

FlagError

0,9

1,0

5,1

5,0

Time TestPointSenseOk

Malfunction of the sensor is found

out, the parameter is equal to zero

Comparing of value of

parameter with set point is authorized

Flag

Logic

level

Sensor

Current,

mA

Sensor operation was normalized,

the measured parameter is calculated

Time

Time

Loading...

Loading...