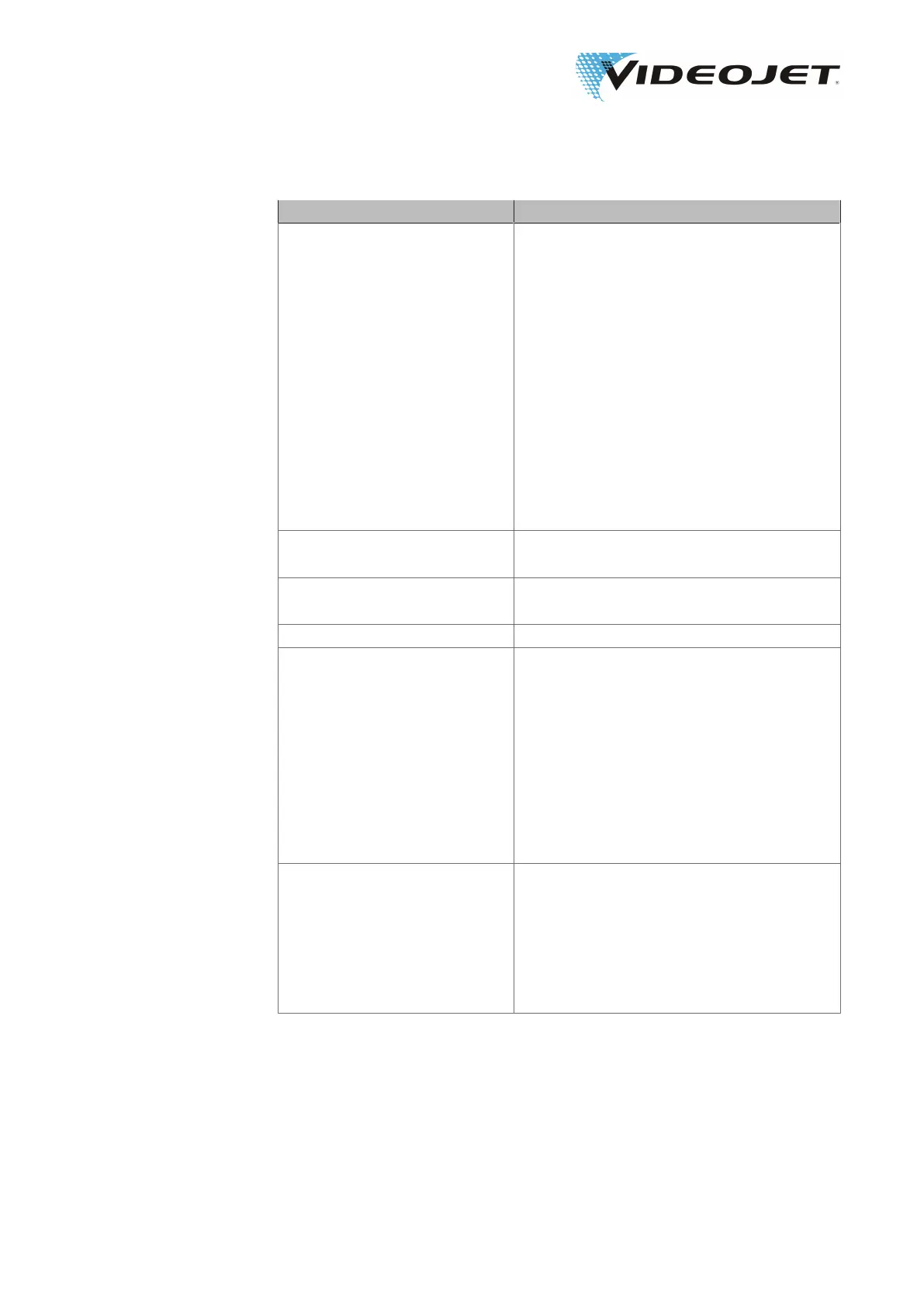

Symptom Causes/Measures

No marking, although START

has been pressed.

• Check the encoder.

• Check the product detection.

• Check the working distance.

• Check the lens. Clean if necessary.

• Check the power setting of the parameter

set.

• Is the correct product registration select-

ed?

• Check the total working time of the laser

beam source.

• Check the external STOP signal (if exist-

ing).

• Error message "Shutter defect", exchange

the shutter.

Lopsided marking. • Check the laser position.

• Check the template.

Shifted marking. • Check the sensor position.

• Check the product carrier for accuracy.

Stretched/shrunk marking. • Check the encoder setting.

Faint marking. • Has the product been changed (e.g. di-

mensions, material)?

• Check the lens. Clean it if necessary.

• Check the working distance.

• Check the parameter set (power too low,

speed to high).

• Check the product (must be free from dirt,

water, dust, oil, etc.).

• Check the fume extractor (must be on and

suitable for the application).

Incomplete marking. • Check the product speed.

• Check the lens. Clean or exchange if nec-

essary.

• Check the product (must be free from dirt,

water, dust, oil, etc.).

• Check the encoder. If it is slipping increase

the tension of the encoder wheel.

09/17 - Index: AD [EN]

55

Videojet 3140/3340/3640/7 Malfunctions

Loading...

Loading...