Service and maintenance

194

Swing gear and bath, greasing

Refilling grease to attachment

Long last bushing (Option)

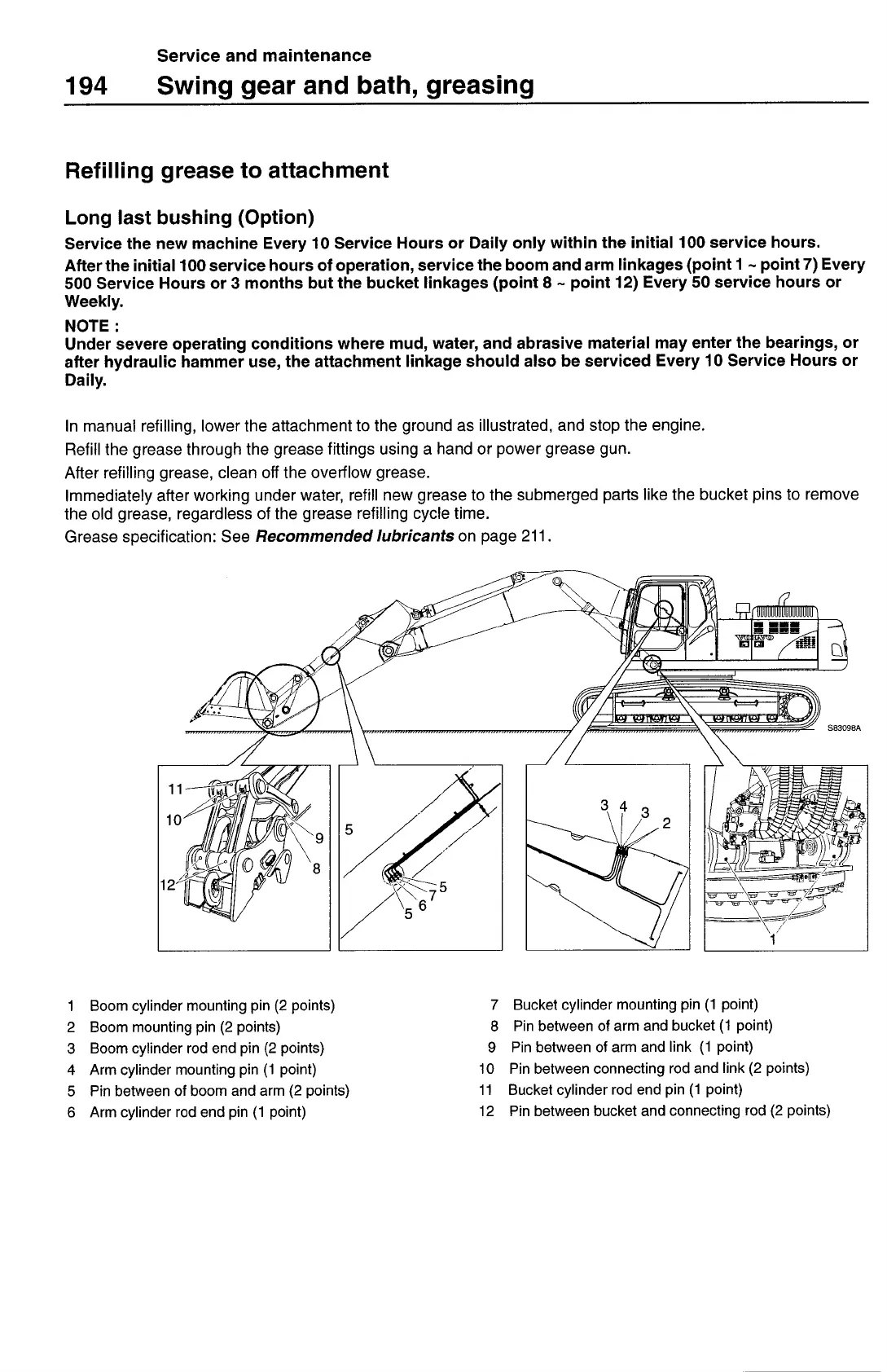

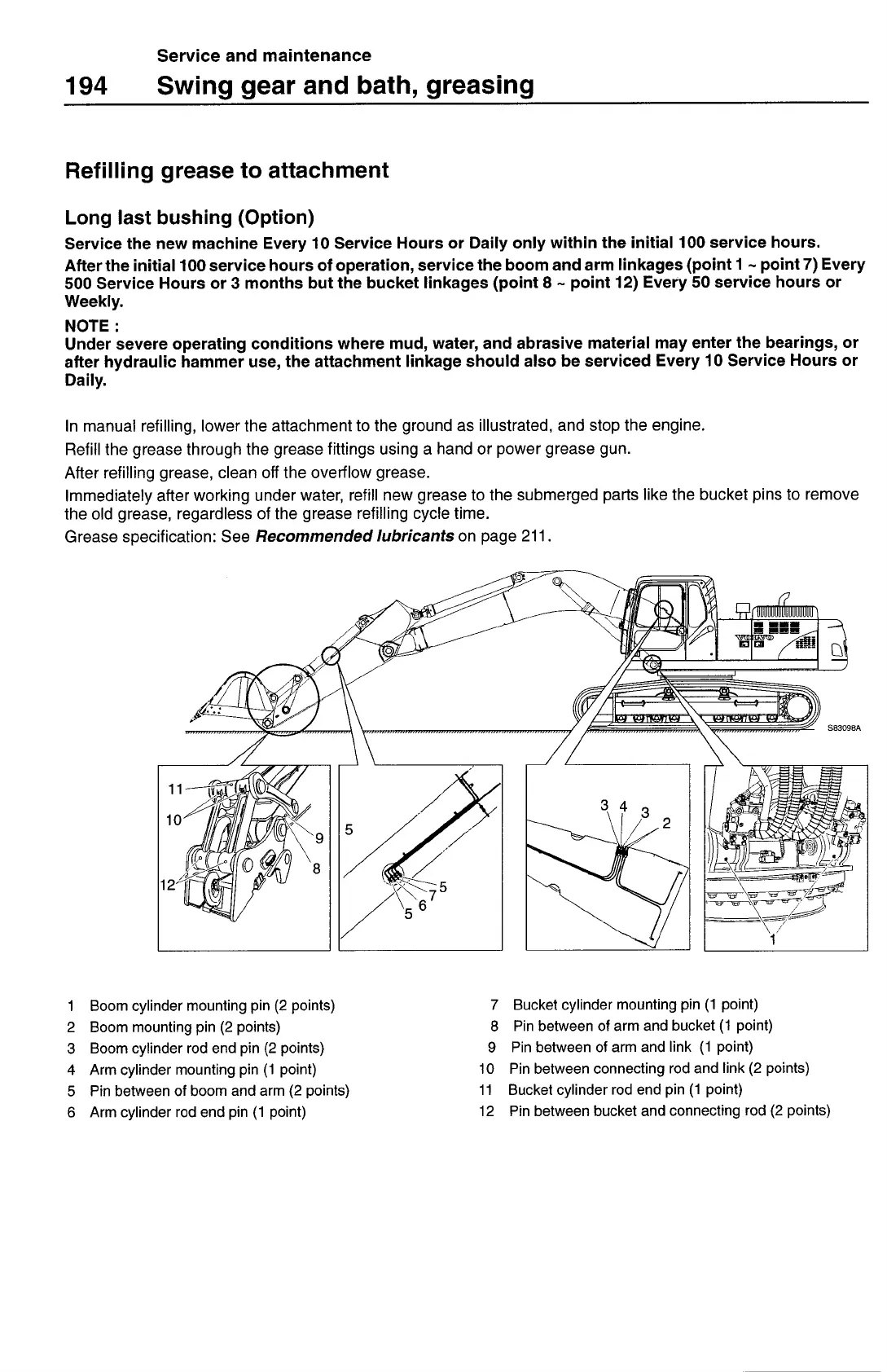

Service the new machine Every 10 Service Hours or Daily only within the initial 100 service hours.

After the initial 100 service hours of operation, service the boom and arm linkages (point 1 - point 7) Every

500 Service Hours or 3 months but the bucket linkages (point 8

-

point 12) Every 50 service hours or

Weekly.

NOTE:

Under severe operating conditions where mud, water, and abrasive material may enter the bearings, or

after hydraulic hammer use, the attachment linkage should also be serviced Every 10 Service Hours or

Daily.

In manual refilling, lower the attachment to the ground as illustrated, and stop the engine.

Refill the grease through the grease fittings using a hand or power grease gun.

After refilling grease, clean off the overflow grease.

Immediately after working under water, refill new grease to the submerged parts like the bucket pins to remove

the old grease, regardless of the grease refilling cycle time.

Grease specification: See

Recommended lubricants

on page 211.

1

Boom cylinder mounting pin (2 points)

7

Bucket cylinder mounting pin (1 point)

2

Boom mounting pin (2 points)

8

Pin between of arm and bucket (1 point)

3

Boom cylinder rod end pin (2 points)

9

Pin between of arm and link (1 point)

4

Arm cylinder mounting pin (1 point)

10

Pin between connecting rod and link (2 points)

5

Pin between of boom and arm (2 points)

11

Bucket cylinder rod end pin (1 point)

6

Arm cylinder rod end pin (1 point)

12

Pin between bucket and connecting rod (2 points)

Loading...

Loading...