Service and maintenance

Track slack 197

Track slack

Inspecting and adjusting the track slack

Check the slack every 100 hours.

WARNING!

When two persons are working, the operator should follow

the sign of the maintenance worker.

For inspecting the track tension, the track must be lifted off

the ground.

Be very careful that the machine does not drop or move

while measuring.

The degree of wear condition of track link pins and bushings varies

with the working condition or the characteristics of soil. Check the

track slack often and keep to specified value.

When working in wet sand or clay, it sticks to and packs between

moving undercarriage components. This can prevent mating parts

from properly engaging each other, causing interference and high

loads. Due to abrasive particles in the material it significant!y ac-

celerates wear rates of the sprockets, pins

I

bushings, idlers and

track links as the track load and tension increase. Generally, pack-

ing effects cannot be controlled except by constant cleaning Ire-

moval of the material.

Therefore thoroughly clean the undercarriage at least daily or

more often according to job-site soil conditions.

Inspection

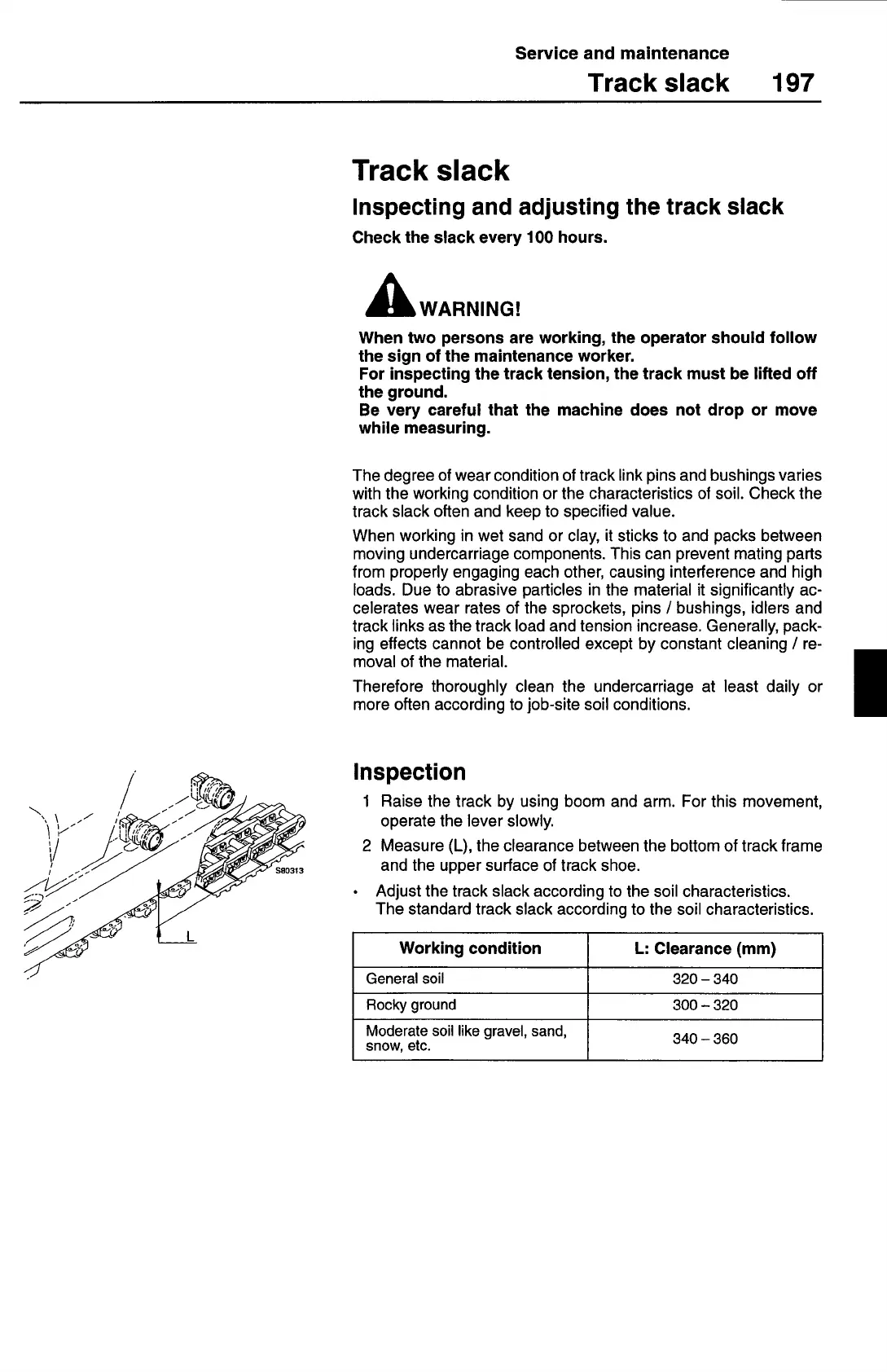

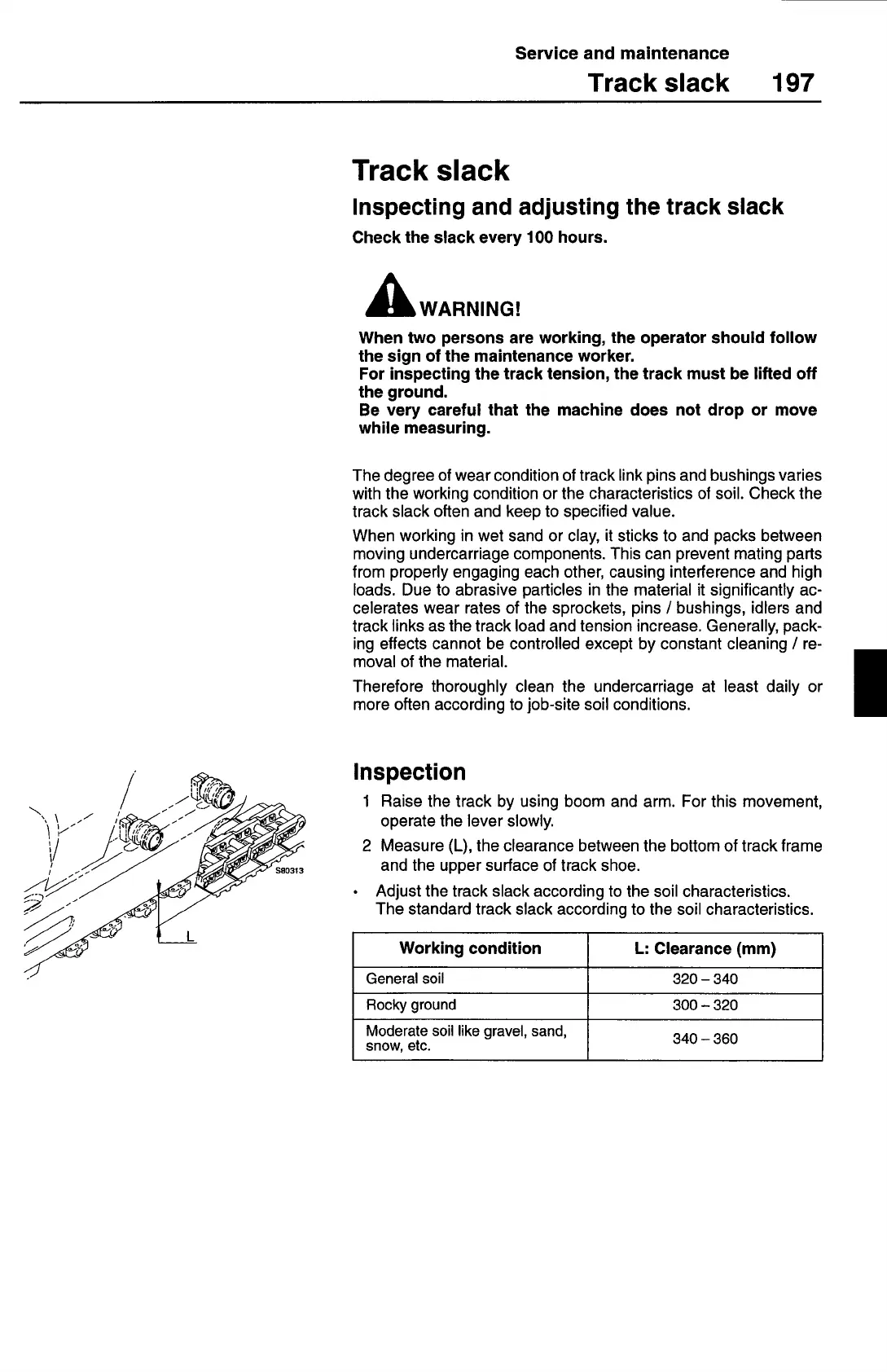

1 Raise the track by using boom and arm. For this movement,

operate the lever slowly.

2 Measure (L), the clearance between the bottom of track frame

and the upper surface of track shoe.

Adjust the track slack according to the soil characteristics.

The standard track slack according to the soil characteristics.

Working condition

L: Clearance (mm)

General soil

320

— 340

Rocky ground

300

— 320

Moderate soil like gravel, sand,

snow, etc.

340

— 360

Loading...

Loading...