27

How to install a steel axle transducer

A single axle transducer is used to monitor one side of an axle. In most cases, two axle

transducers will be installed per axle, one on the suspension for the left wheel, one on the right.

Ensure that you select the appropriate position for the sensor. Please see “Sensor installation

positions” on page 23 for guidance on selecting a position for a sensor

1. Clean and dry the surface where the transducer will be mounted to

the suspension system:

• Use brake cleaner and scotchbrite to remove heavy debris

• Use alcohol wipes provided to ensure all grease is removed

Loose paint and rust must be removed. The site must be dry before

installation

2. Ensure the mounting surface is at an appropriate temperature:

• The ideal temperature of the mounting surface is 70°F / 21°C

• If required, warm the spring with a hot air gun before bonding the

transducer

It is not recommended to apply the bonding tape at temperatures below 60°F / 15°C

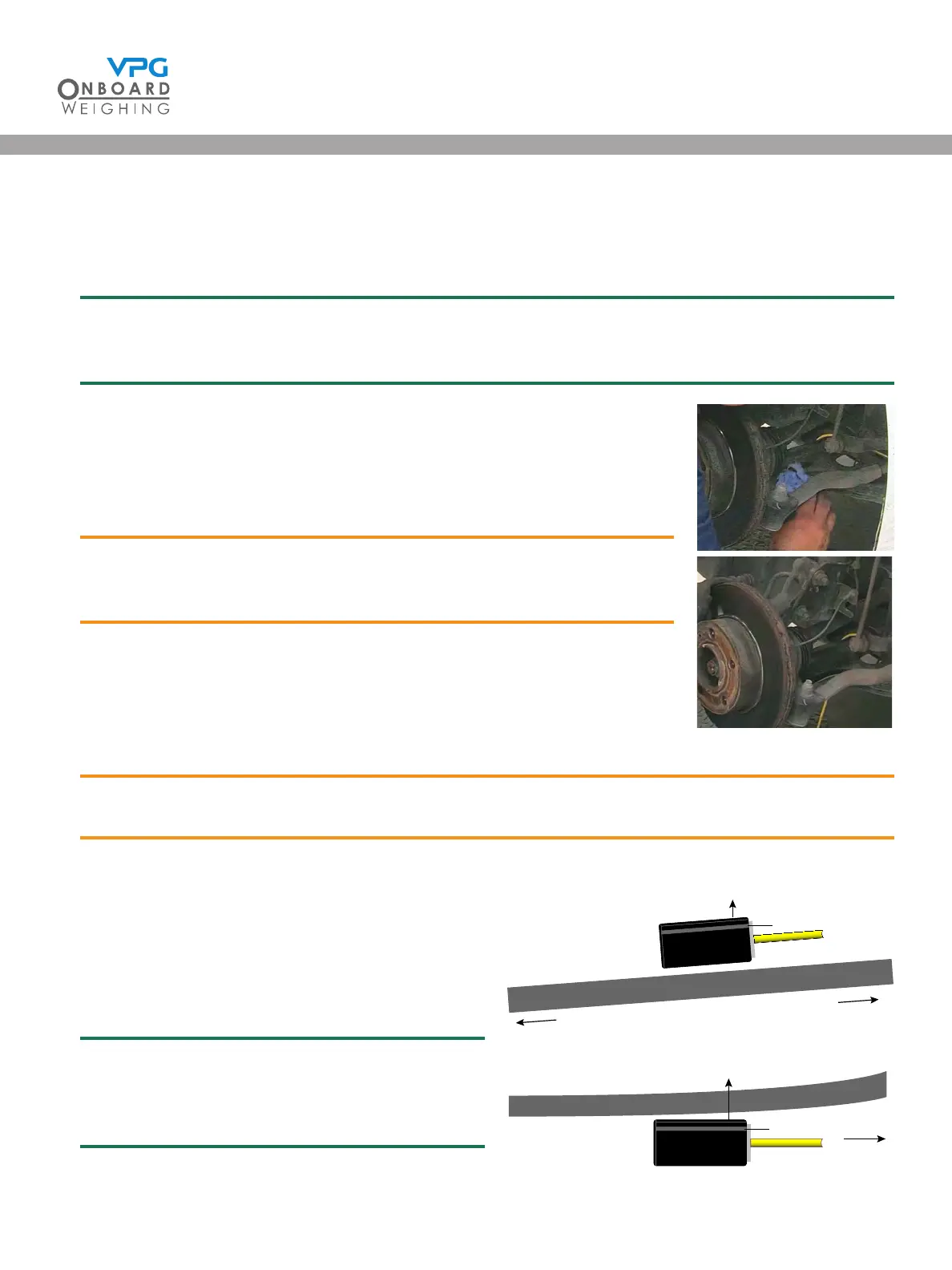

3. Warm the bonding tape in your hands and apply it to the appropriate side of the sensor:

• The sensor must always be mounted with

the face adjacent to the groove pointing up

• The sensor must always be mounted with

the internal domain cable pointing towards

the pivot point on the suspension system.

Please see “Sensor installation positions” on

page 23 for further guidance on sensor

orientation in specic suspension systems

Mounted to the top

of the wishbone

Wishbone

pivot point

Side adjacent to the

groove facing up

Groove

Wheel

Mounted to the bottom

of the spring (bogie)

Spring

pivot point

Side adjacent to the

groove facing up

Groove

VanWeigh

®

VanWeigh

®

Loading...

Loading...