24

(1)(1)

(1)

(2)

(3)

(7)

(6)

(5)

(4)

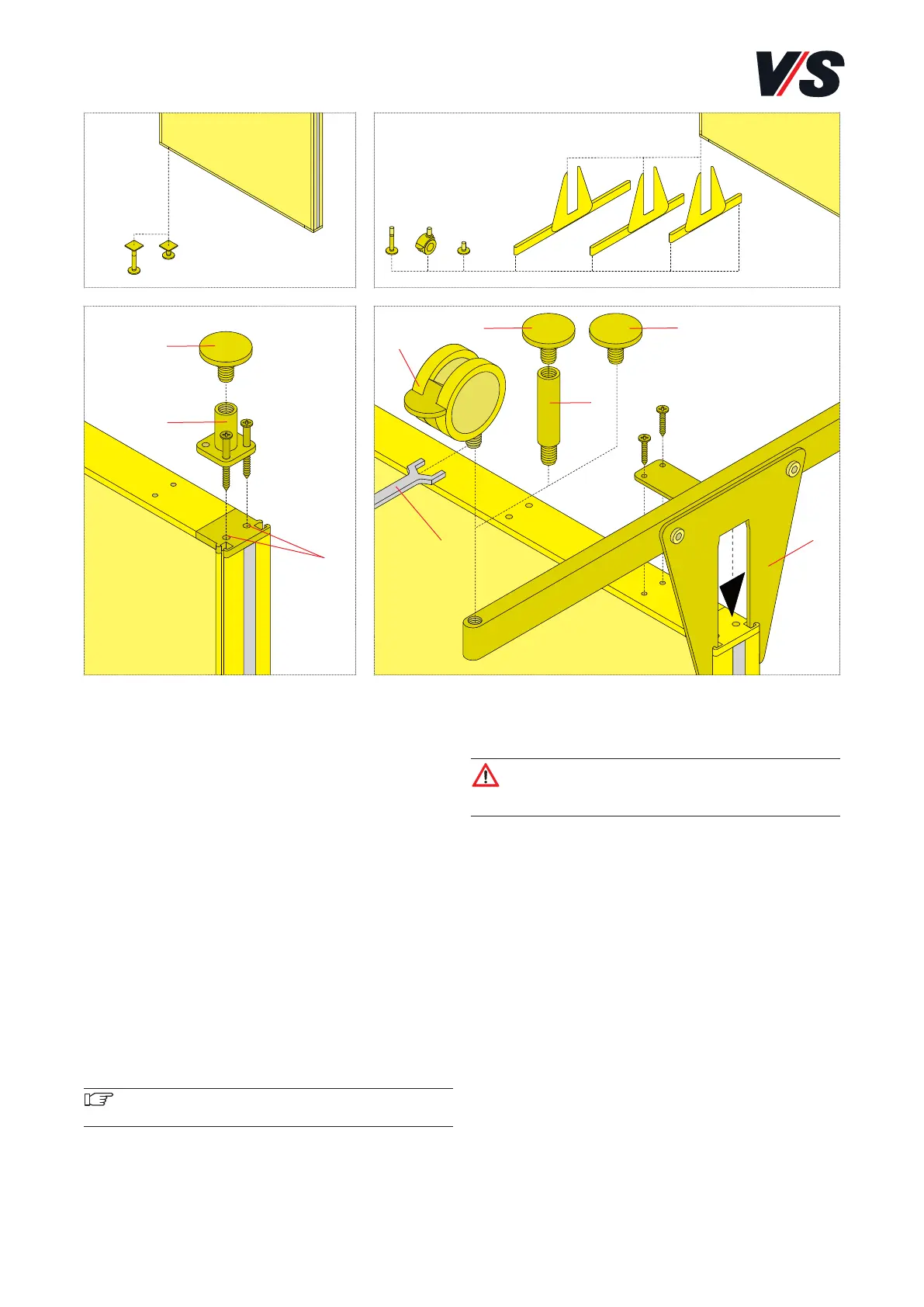

Align the gusset plate (6) and secure in the aluminium

profile with 2 4.8 x 19 pan-head tapping screws.

Caution! The long stabiliser side may pose a tripping

hazard! Eliminate this hazard by engaging a storage

board at a height of 1 to 1.3 m.

Mounting glide elements on stabiliser: Screw glide element

(1) into the female thread of the stabiliser, see Stand foot.

Mounting castors on stabiliser: Screw castor (4) into the

female thread of the stabiliser, see Stand foot. Mounting

spacer on stabiliser: (to obtain the castor height) Screw

spacer (5) with glide element (1) into the female thread of

the stabiliser, see Stand foot.

5. Functional screen. Mounting stand

foot and stabiliser.

Assembling functional screen with stand feet. Models

05430-05443.

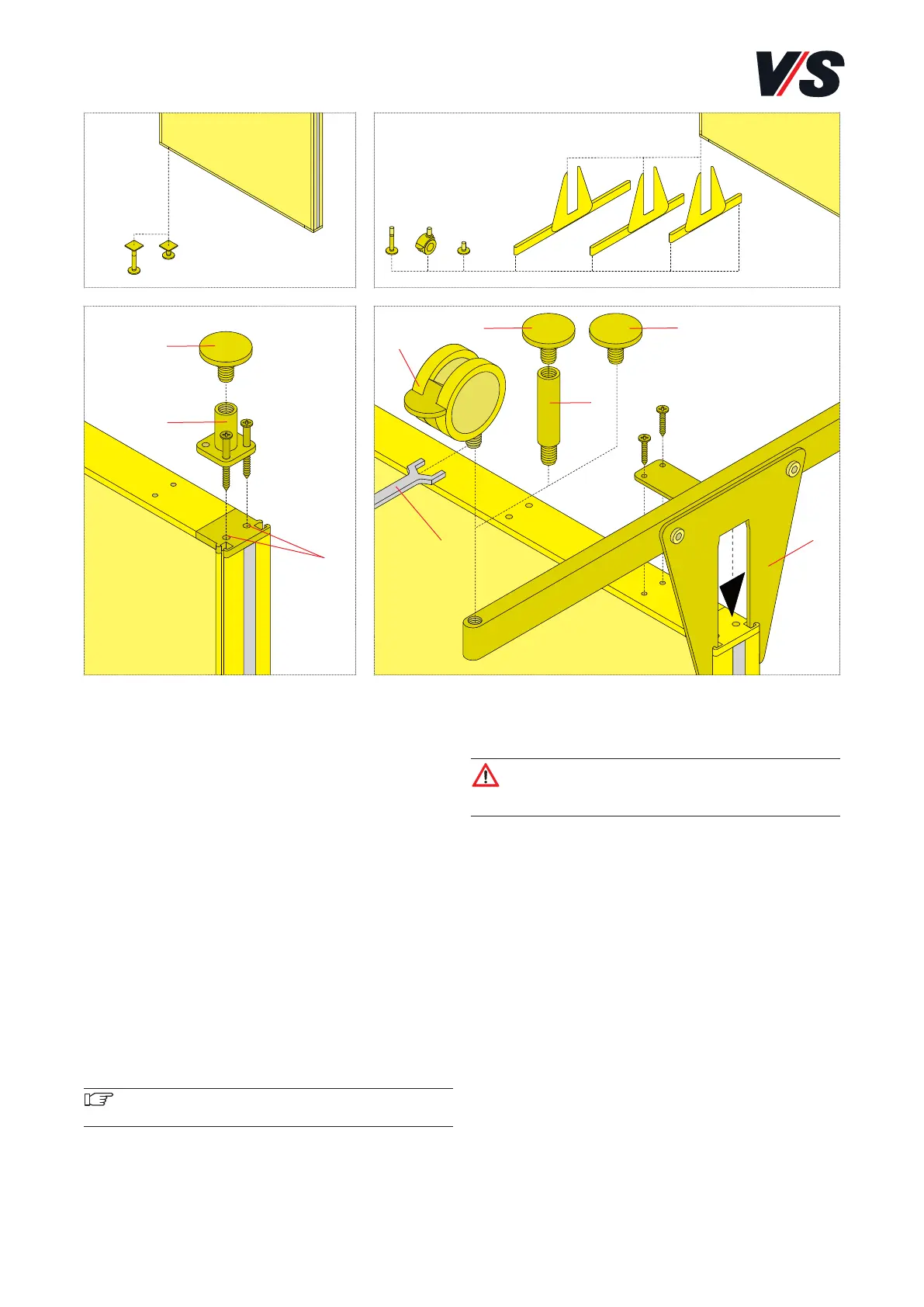

Mounting stand foot: Secure base assembly (2) with 2 4.8 x

60 pan-head tapping screws in screw channel (3) of the

clamping rail. Screw glide elements (1) back into the base

assembly.

Or: Screw castor (4) into the female thread of base assem-

bly (2) with 12 WAF (7).

Or: (to obtain the same height as with castors) Screw spacer

(5) into the female thread of base assembly (2). Screw glide

element (1) into the female thread of spacer (5).

Assembling functional screen with stabiliser. Models

05400-05413, 05415-05428.

Long stabilizer on one side = Maximum total load of 20 kg

on long stabilizer side, no loading of the functional screen

permitted on the short stabilizer side.

Important! This is a tight fit because the gusset plate

is prestressed.

Loading...

Loading...