34

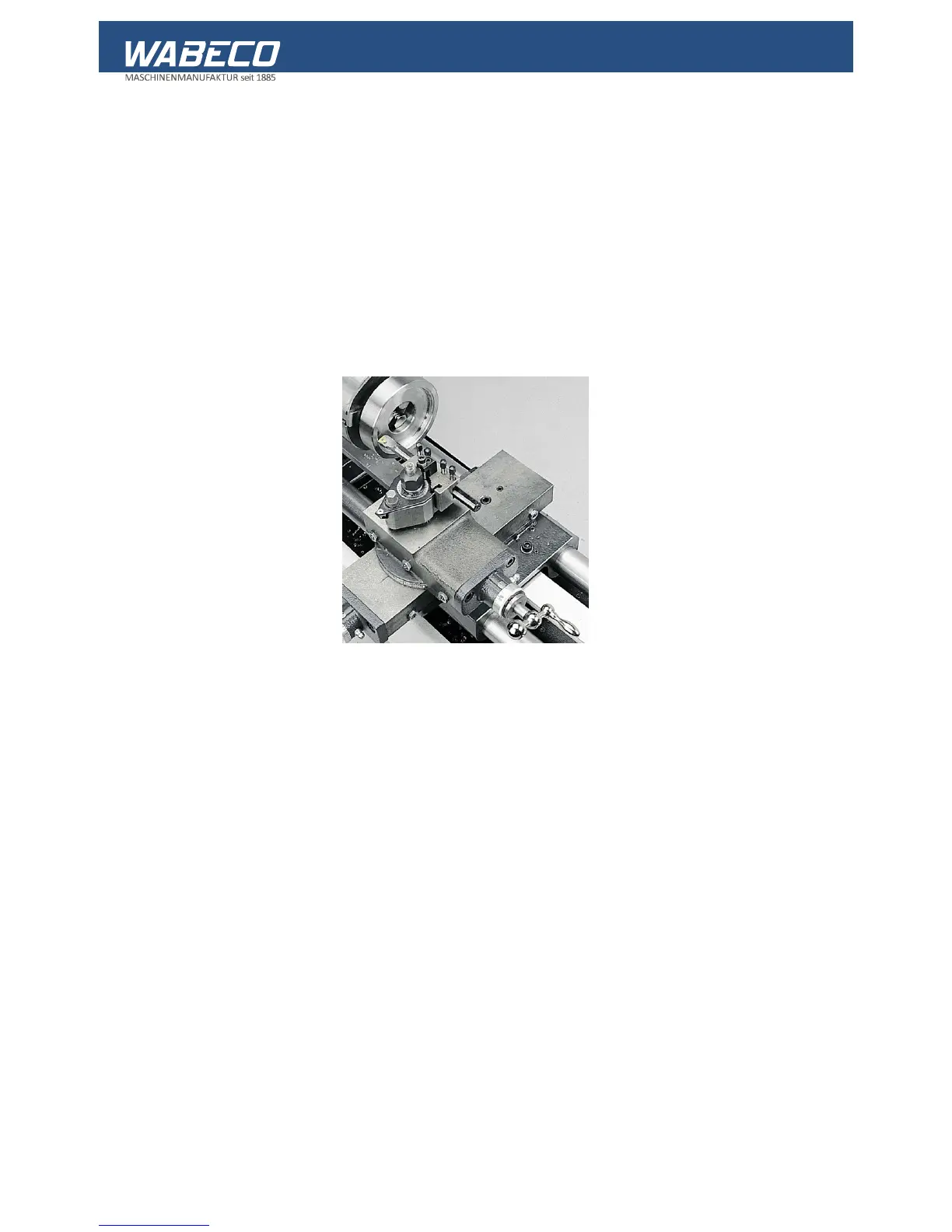

10. Readjustment tool skid

The tool skid consists of the longitudinal- and transverse skid. The corresponding dovetail guides are

adjustable constructed.

If adjustment is required, please proceed as follows:

1. Undo counter nuts

2. Using a pin wrench tighten the regulating screw in such a way that the skid is still able to move

easily.

3. After setting, tighten the counter nuts back up again

Longitudinal skid:

■ The longitudinal skid is constructed upon the transverse skid.

■ The same can be panned 360 degree.

■ This enables the longitudinal skid to lathe cones.

■ To adjust, an Allen key of the size 4 is used to undo the screws positioned on both outsides of the

transverse skid.

■ The altitude of the longitudinal skid is referred by the mark upon the transverse skid.

■ Upon the longitudinal skid a degree scale can be found.

■ The distance between scale mark to scale mark equals to 1 degree.

Scale ring:

■ To adjusting the lathe tools the support spindles have scale rings with scale marks.

■ One mark on the scale corresponds to an adjustment of 0.05 mm.

■ At the cross skid this corresponds to a chip dismounting of 0.1 mm upon the work piece.

■ At the longitudinal skid this corresponds to a chip dismounting of 0.05 mm.

■ If the tool skid shall be mounted onto the guide rods (such as during the process of surfacing) then

the Allen screw is to be used in order to tighten the clamp which is positioned on the bottom of

transverse skid onto both guide rods.

Loading...

Loading...