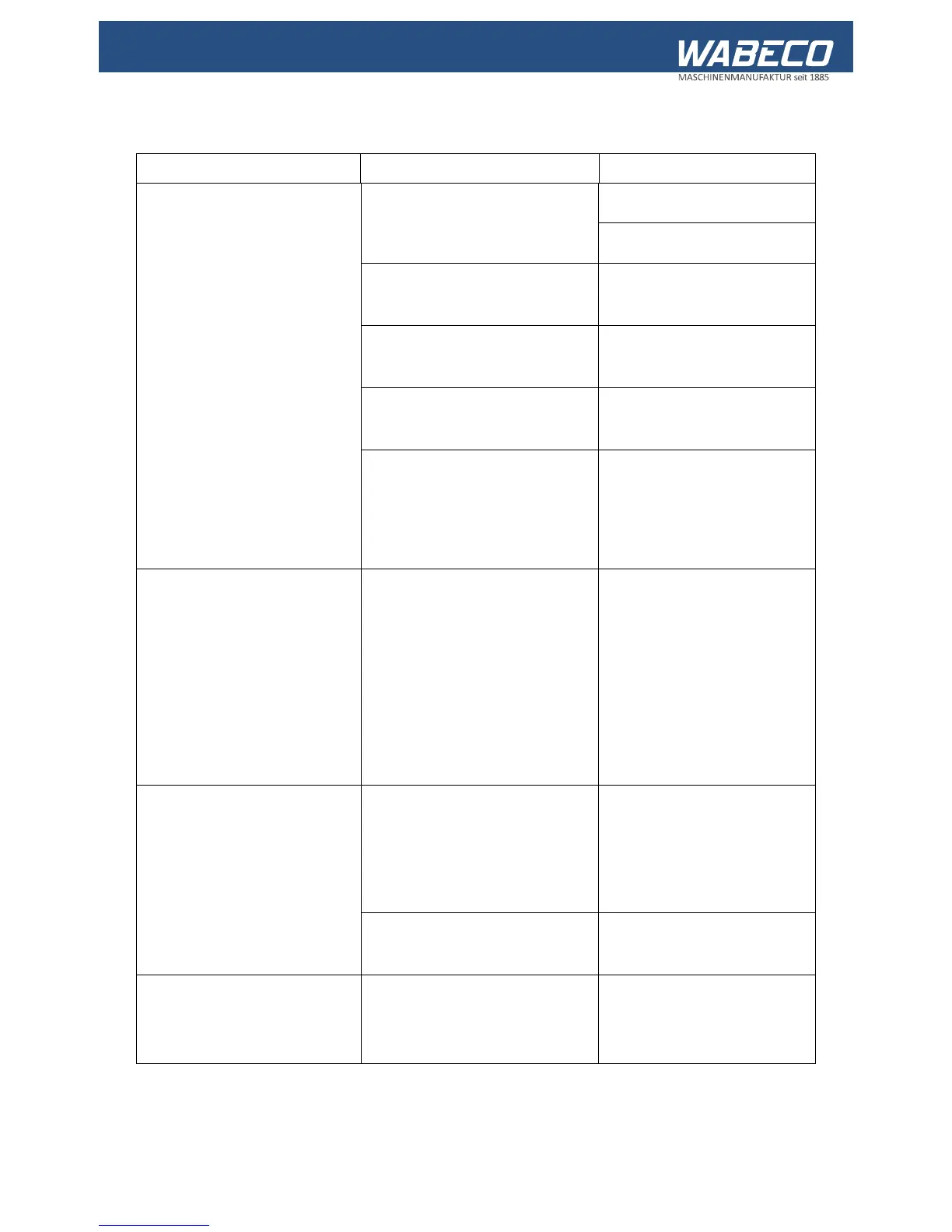

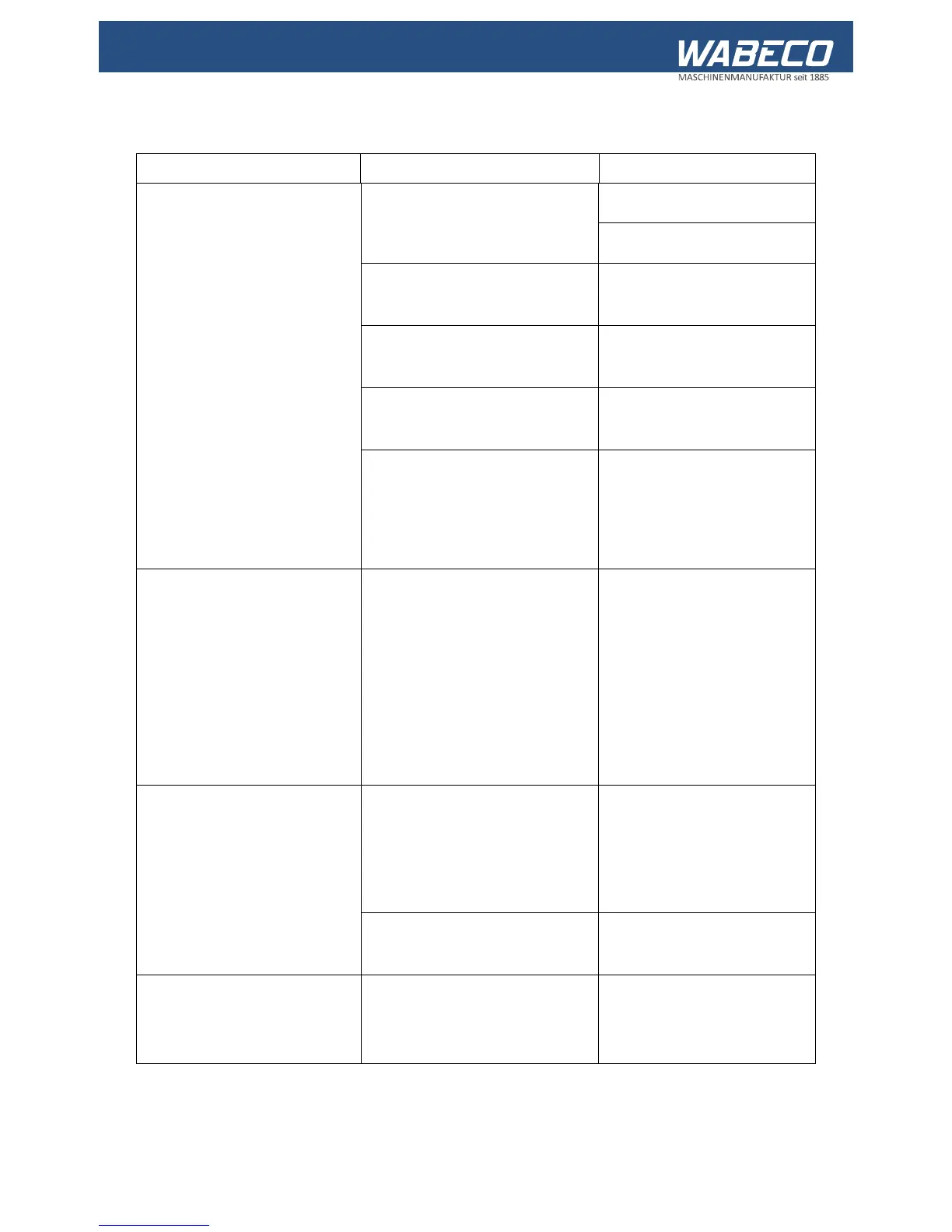

13. Operational faults and the elimination of such

Operational faults Possible cause Remedy

Machine cannot be switched on

230V voltage is not present

Plug is not fitted correctly

Check the fuse for the socket

The chuck protection hood is not

closed

Close the chuck protection

hood

Emergency off switch not

unlocked

Unlock the emergency off

switch

Direction of rotation has not been

selected

Select the direction of rotation

at the turn switch

Vibrations (e.g. by transportation)

have caused the plugged contacts

of the drive motor (1.4 kW) board

to come undone

Pull the power plug!

Remove the cover sheet of the

electronic housing and check

Main spindle motor no longer

starts after the unlocking of the

emergency off switch

Motor controller must be unlocked For machin

drive motor, the motor must be

switched on again using the

ON/OFF switch after the

emergency off switch is

unlocked. After unlocking, wait

approximately 5 seconds

before switching the machine

on.

The drive motor (1.4 kW)

experiences "skips" during

operation

Carbon brushes and collector of

the drive motor are contaminated

Clean the carbon brushes and

collector of the drive motor

with a piece of coarse

sandpaper

(See "Maintenance" section)

Carbon brushes are worn Replace carbon brushes with

new ones

Tool skid cannot be moved or

can only be moved with

considerable force

Clamping of the tool skid is on Open the clamping

Loading...

Loading...