38

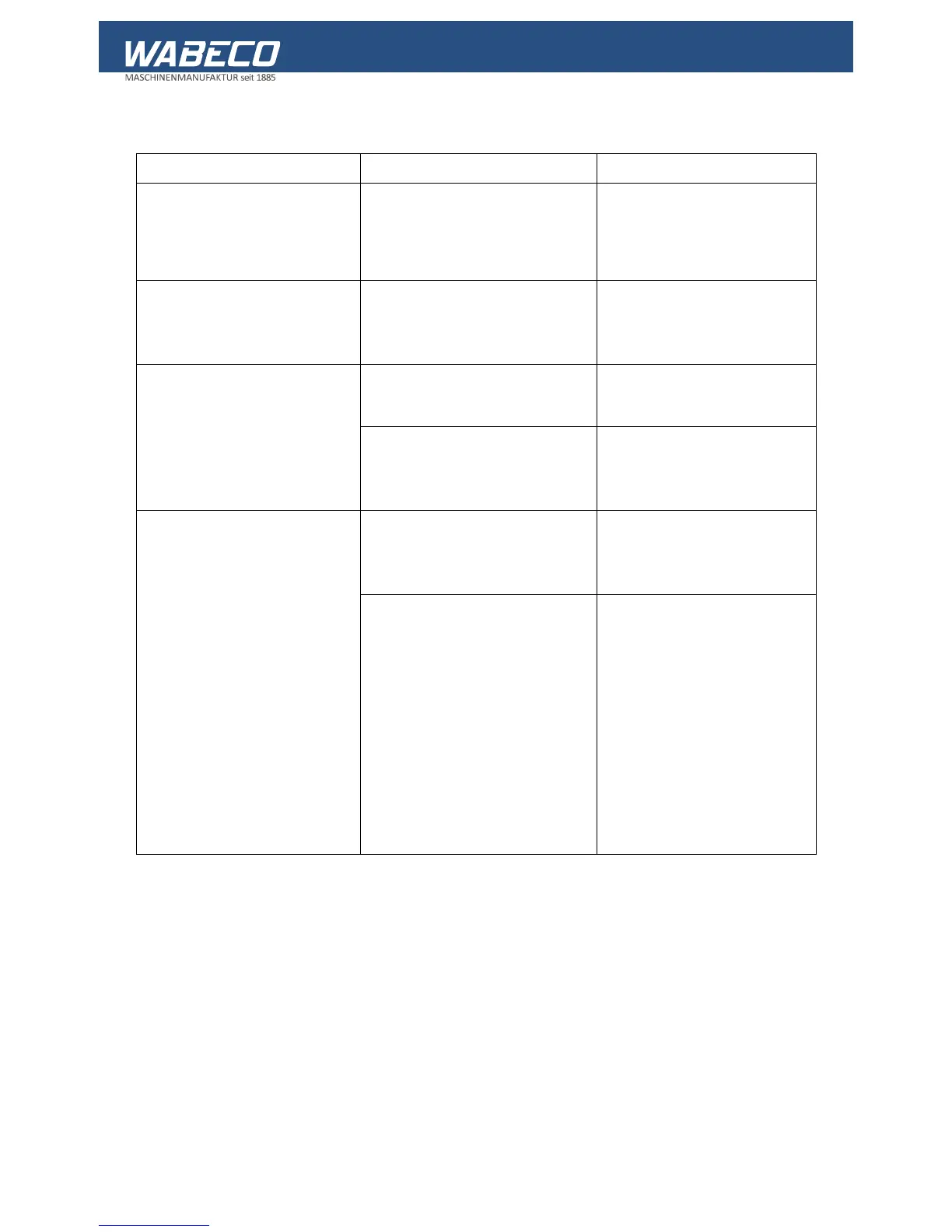

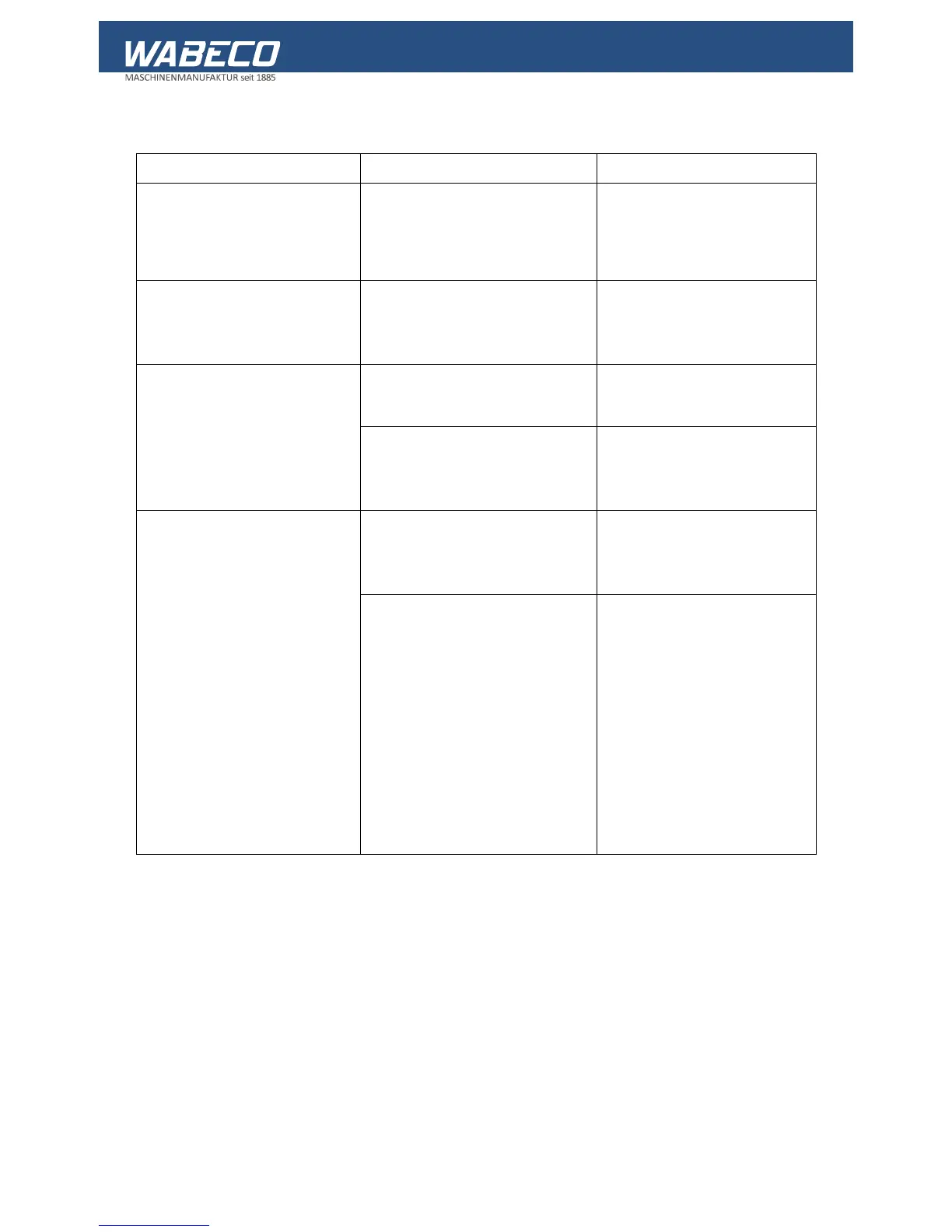

13. Operational faults and the elimination of such

Operational faults Possible cause Remedy

Transverse or longitudinal skid

cannot be moved or can only be

moved with considerable force

Guide play is set too narrowly Adapt the guide play

Rust on work pieces of machine

parts when using coolant

lubrication

Wrong coolant set Check the mixing ratio of the

coolant and correct if required

(never cool with water alone!)

Tool holder cannot be inserted

into the main spindle

An incorrect tool taper of the tool

holder has been used

Only use the appropriate tool

holders for the machine

Inner core of the reducing sleeve

or outer cone of the tool holder is

contaminated

Clean the relevant cone

Tool cannot be removed from

the tailstock sleeve

Tailstock sleeve is not fully

cranked back

Fully crank back the tailstock

sleeve to automatically eject

tools with ejector lugs

Use tool without ejector lugs Place a soft and sufficient wide

inlay between the tool and

tailstock front. Now crank the

tailstock sleeve back to push

the tool out.

lugs is possible by screwing a

suitable threaded pin into place

which extends the length of the

tool backwards)

Loading...

Loading...