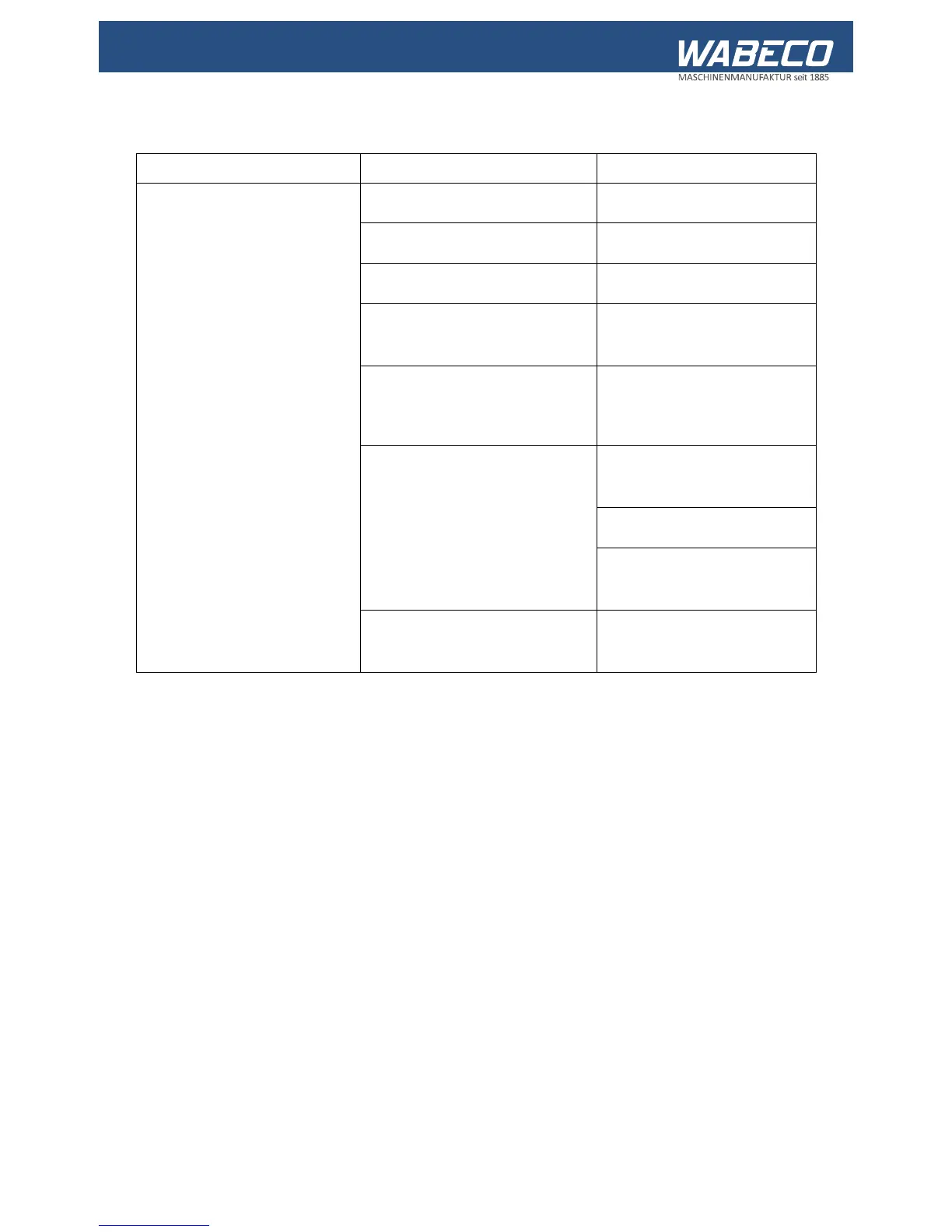

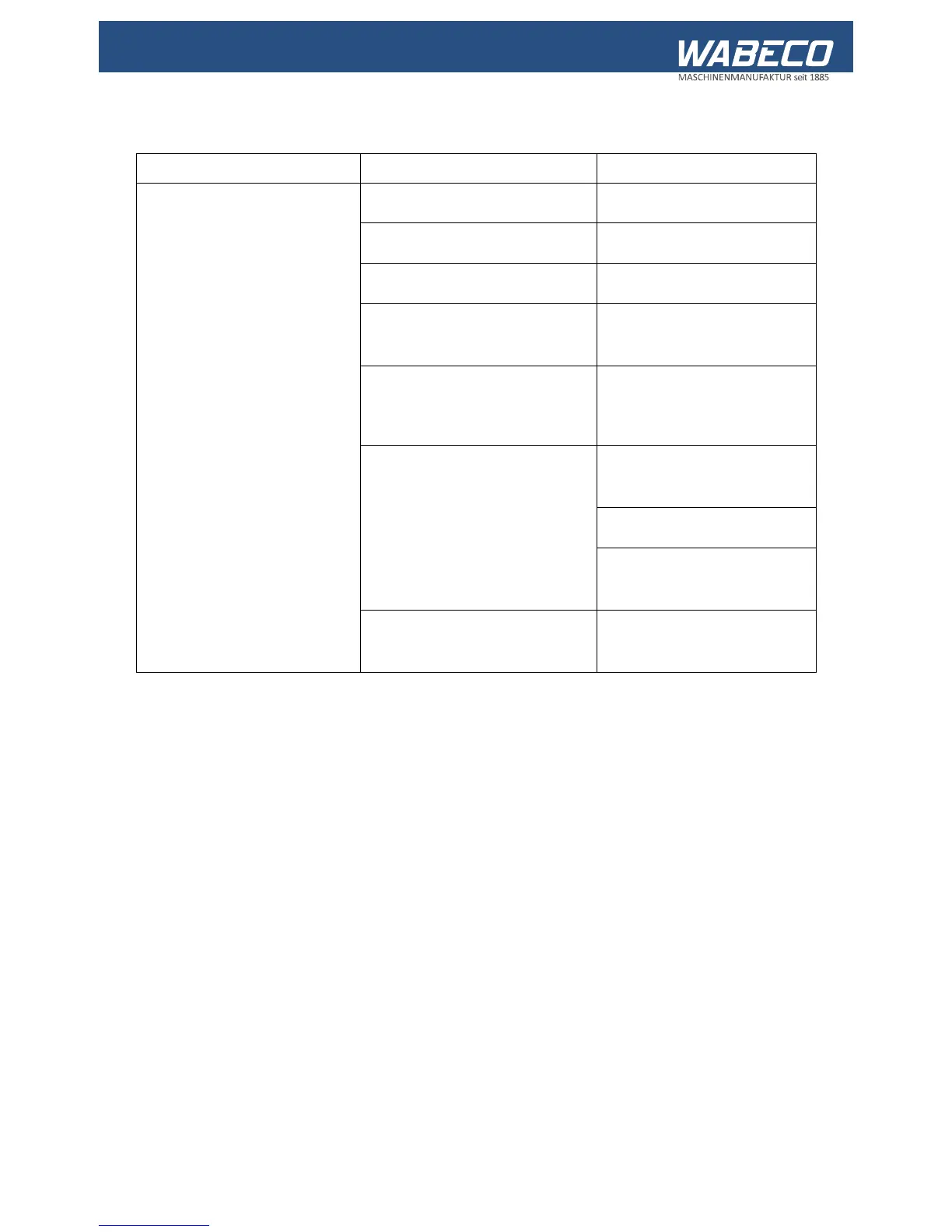

13. Operational faults and the elimination of such

Operational faults Possible cause Remedy

Tool overheated Revolutions too high Reduce the revolutions

Feed too high Reduce the feed

Working without coolant Use coolant

Insufficient coolant feed at the

cutting edge

Align the coolant hose correctly

Tool blunt

Sharpen tool or use a new tool

Increased friction caused by

shaving build up in the tensioning

groove of the tool (drilling work)

Remove the shavings from the

hole more frequently (withdraw)

Use a coated tool

Wash the processing area with

coolant

Unsuitable tool chosen for the

material to be processed

Only use the suitable tool for

the relevant material

Loading...

Loading...