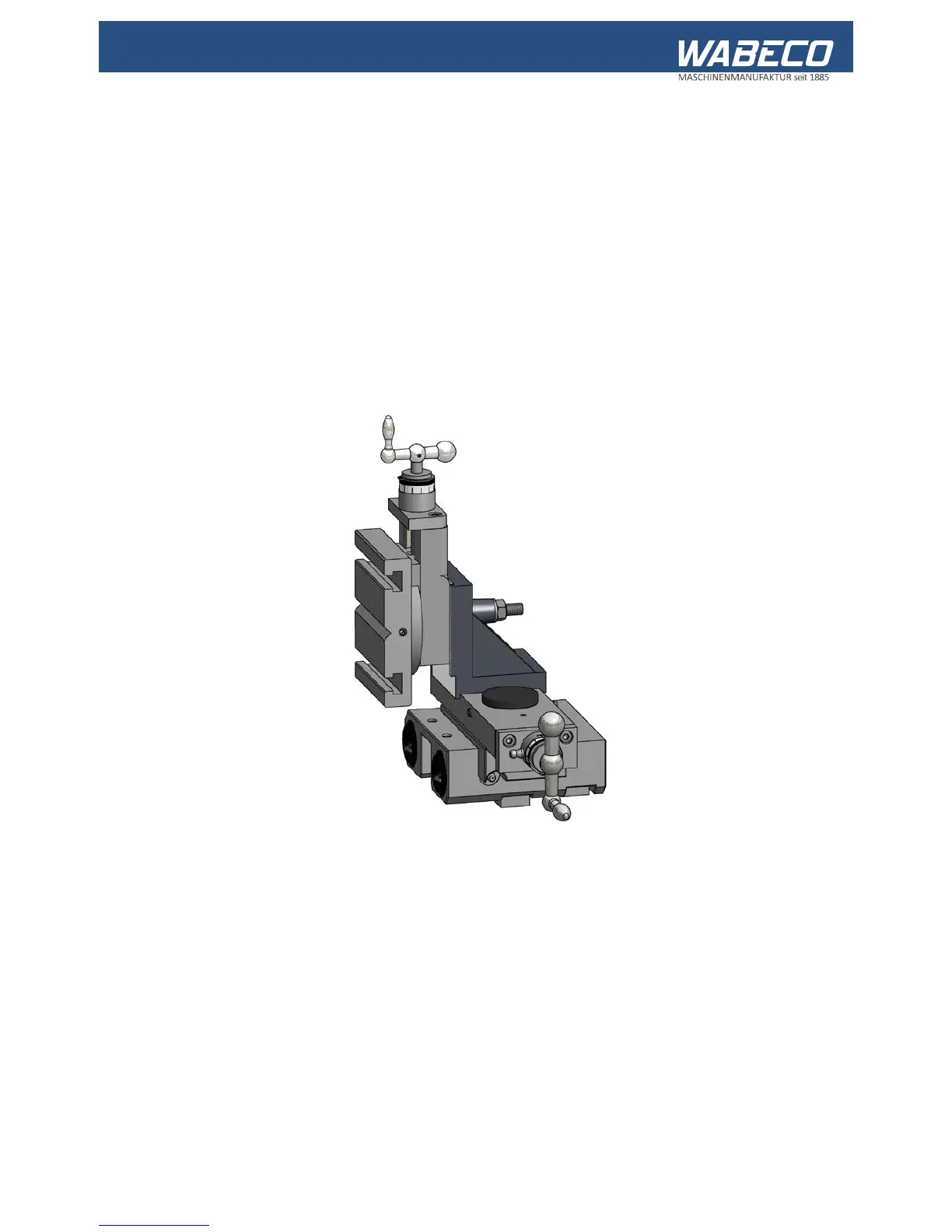

21. Tensioning bracket with milling machine table (optional)

For drilling and milling work

■ For creating even surfaces and grooves.

■ The feed and return motions are carried out by the work piece.

■ Put the used clamping screws into the T-groove of the clamping plate. It is necessary that the

corresponding clamping screw fit to the clamping plate.

■ The machine bench vice can also be mounted up on the clamping plate.

■ The tool must be clamped as short as possible in the collect (risk of breakage).

■ The depth adjustment takes place with the feed shaft in case the tool is firmly clamped.

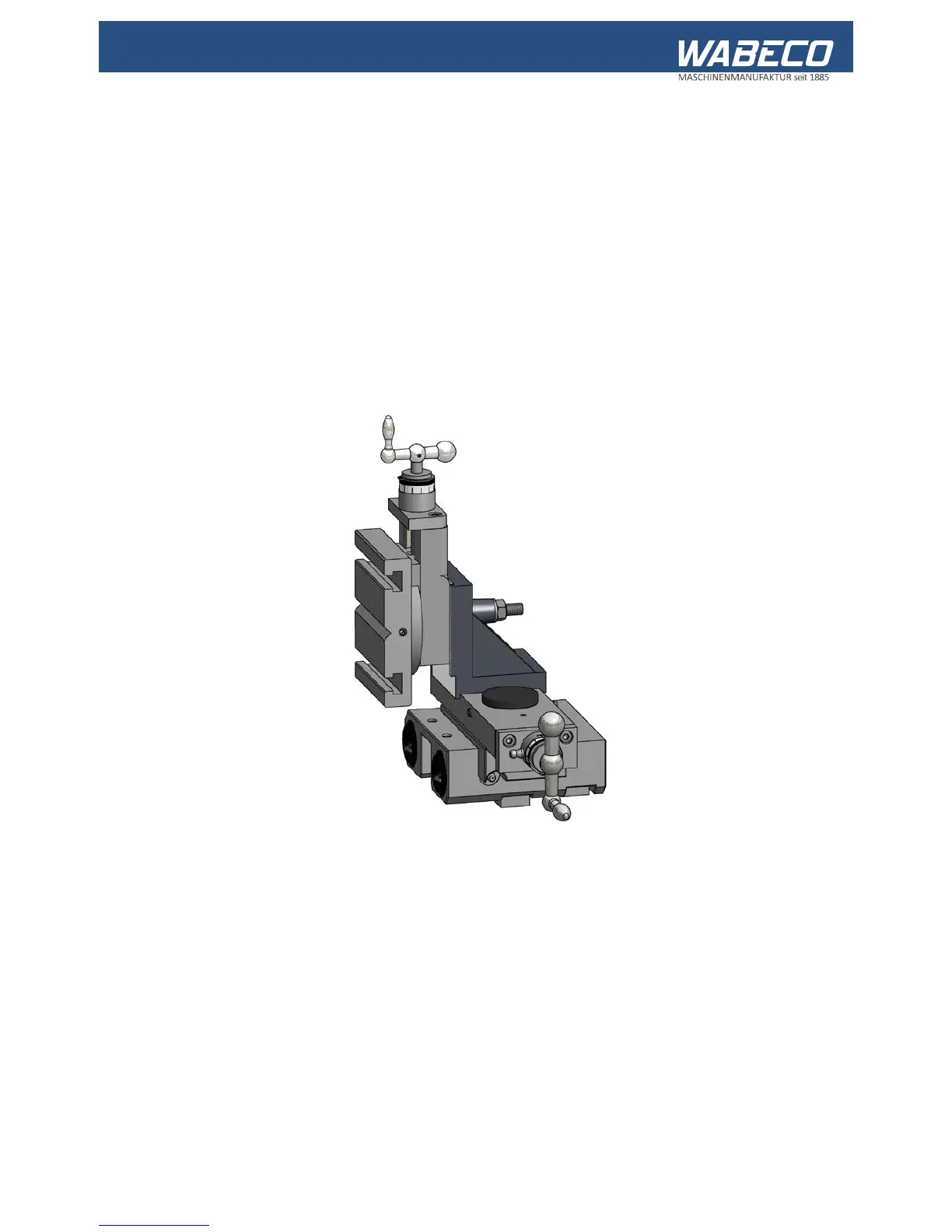

21.1 Mounting of the tensioning bracket with milling machine table

1. Unscrew both screws (3) with an Allen key of size 4 and remove the push pieces (2).

2. Remove the longitudinal skid (5) from the transverse skid (1) of the lathe.

3. Clean the transverse skid from dirt and shavings to ensure a proper support.

4. Position the clamping bracket (3) as shown upon the transverse skid.

5. Combine the washer (10) with the screw (9) and push the screws from below, through the bored

holes in the clamping bracket and tighten using an wrench of size 16mm.

6. Remove the clamping plate including the spring (or in some an mounted the rapidly changing

switch) from longitudinal skid.

7. Put the longitudinal skid upon the clamping bracket as shown. Combine the nut (12) with the

washer (11) and position it upon screw pin of the longitudinal skid and tighten these.

Loading...

Loading...