Troubleshooting 79

5

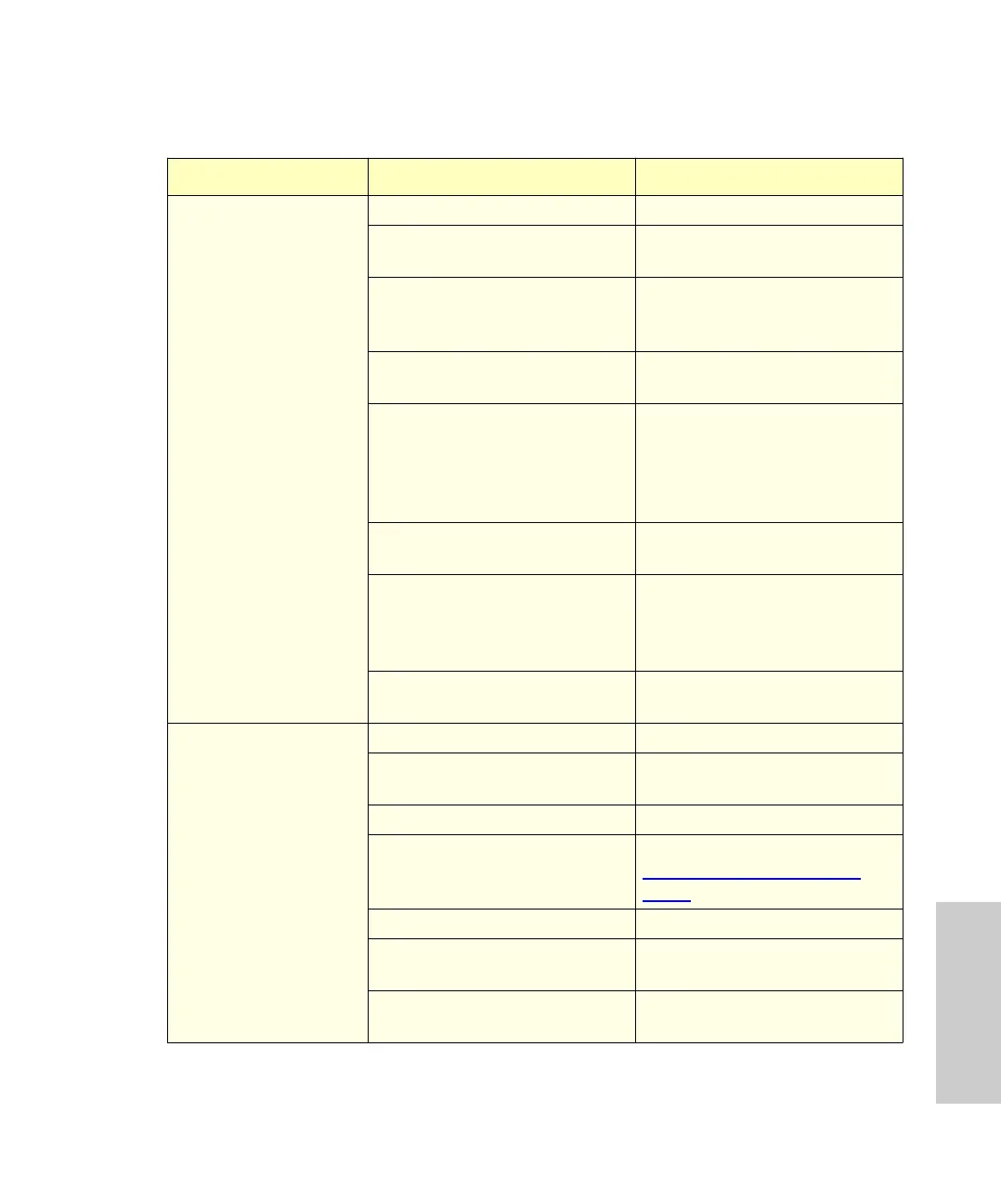

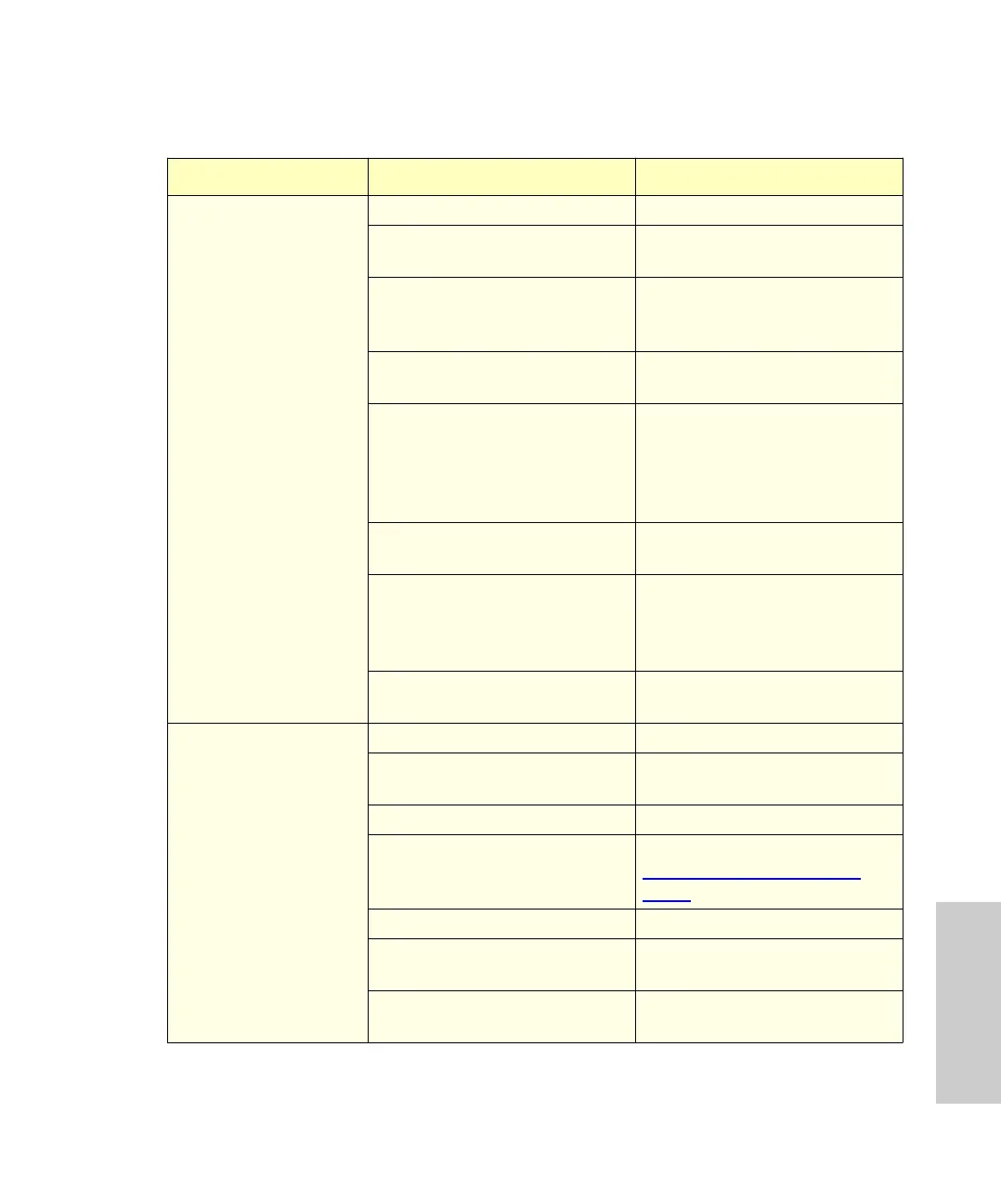

Table 5-1 Correcting Pump Problems

Symptom Possible Cause Corrective Action

High pressure Pump flow rate set too high Set the correct flow rate.

High-pressure limit set too low Set the high-pressure limit to

the correct value.

Blocked column Clean the column according to

the column care and use

manual.

Blocked mixer Backflush or disassemble the

mixer.

Viscous eluents in use Check eluent viscosity (the

observed pressure may be

normal for the column/eluent

blend). If necessary, change to

a less viscous eluent.

Defective pressure transducer Contact Waters Technical

Service.

Blocked outlet tubing or fluid

path (in pump outlet, detector,

column, or injector)

Locate the source of the

blockage. Clean or replace

tubing according to the appro-

priate operator’s guide.

Ambient temperature has

changed

Stabilize the operating

temperature.

Low pressure Pump flow rate set too low Set the correct flow rate.

Low-pressure limit set too high Set the low-pressure limit to

the correct value.

Eluent reservoir empty Fill the reservoir.

Air in eluent lines Prime the pump (see

Section 3.2.1,

Priming the

Pump).

Incorrect eluent used Use the correct eluent.

Leaks Carefully tighten any loose

fittings.

Ambient temperature has

changed

Stabilize the operating

temperature.

Loading...

Loading...