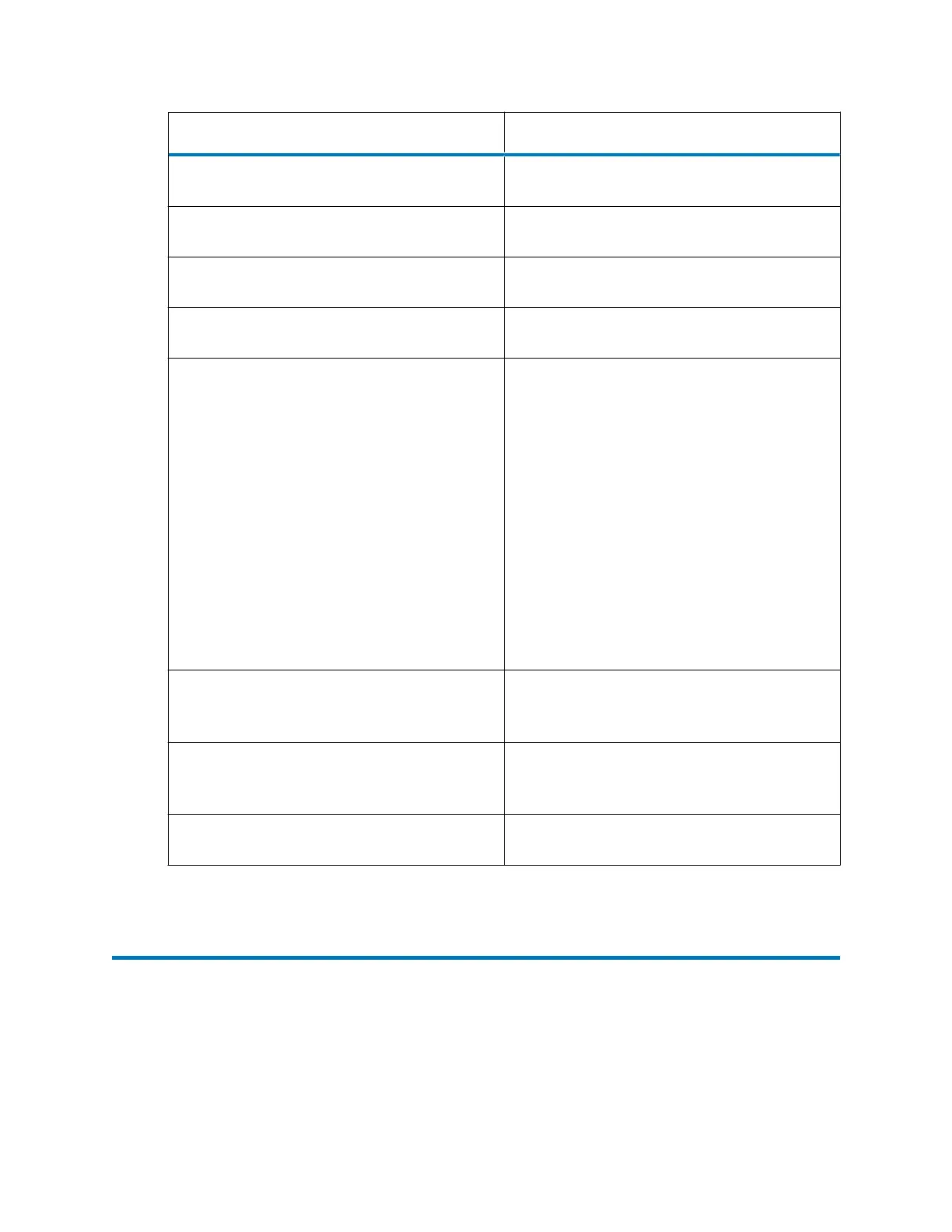

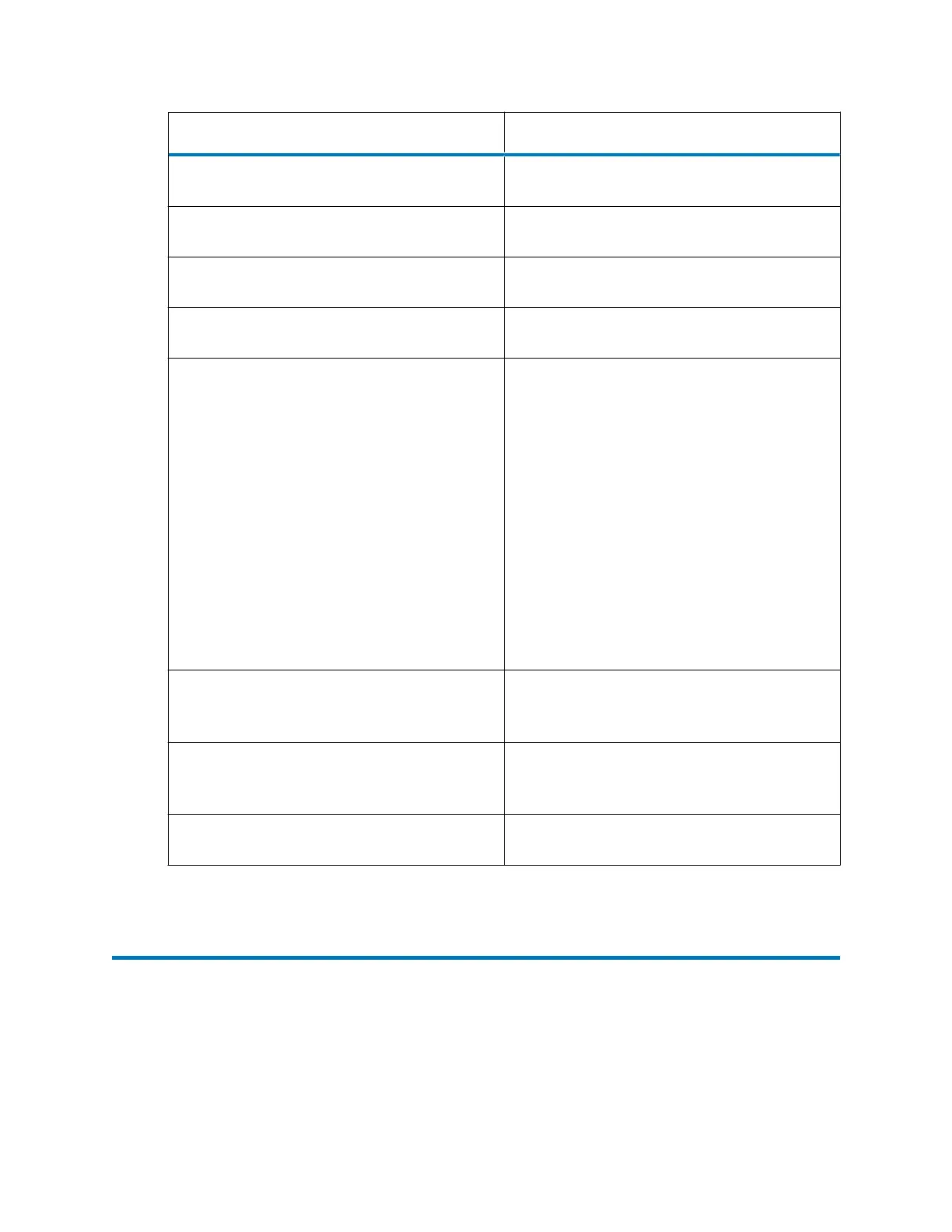

Suspected cause Possible solution

µSM-FL temperature is too high or low. Adjust the µSM-FL sample compartment

temperature.

Sample syringe draw speed set too high,

resulting in too little sample draw-up.

From the Method Editor, program a slower

draw speed.

Sample diluent composition contains too much

organic, resulting in poor peak shape.

Decrease organic in the sample diluent.

Vial position is incorrect. Program the correct vial position in the sample

list.

Incorrect sample preparation and sample

composition resulting in, or due to, one or more

of the following:

• Sample concentration too low

• Sample is not completely in solution

• Volatile sample is evaporating

• Sample is degraded

• Sample precipitated over time

• Sample prepared incorrectly

• Sample buffers and acids inappropriate for

the injection method selected

Select the appropriate sample preparation

method for the injection method selected and

remake if necessary.

Glassware incorrect or contaminated See also: Controlling Contamination in Ultra

Performance LC/MS and HPLC/MS Systems

on the documentation CD.

Vial, vial cap or well plate cap mat failure or

malfunction.

See also: The Waters vials, filters, and plates

selector at www.waters.com/app/selector/en/

index.html.

Column viability in question. See also: The appropriate column care and

use manual on the documentation CD.

4.4 Configuring maintenance warnings

Maintenance counters, if available for a particular component, provide information about real-time

usage that can help you determine when to schedule routine maintenance for specific

components. You can specify usage thresholds and maintenance warnings that alert you when a

component reaches a specified threshold. You can minimize unexpected failures and

unscheduled downtime during important work. For information explaining how to specify

maintenance warnings, consult the Waters console Help.

November 26, 2019, 715003588 Revision C

Page 74

Loading...

Loading...