NOTE:

Both Header Temp Sensor and 4-20ma Direct Drive must be wired. See the Edge [i]

Controller Manual (OMM-0141, GF-213-B) for more information.

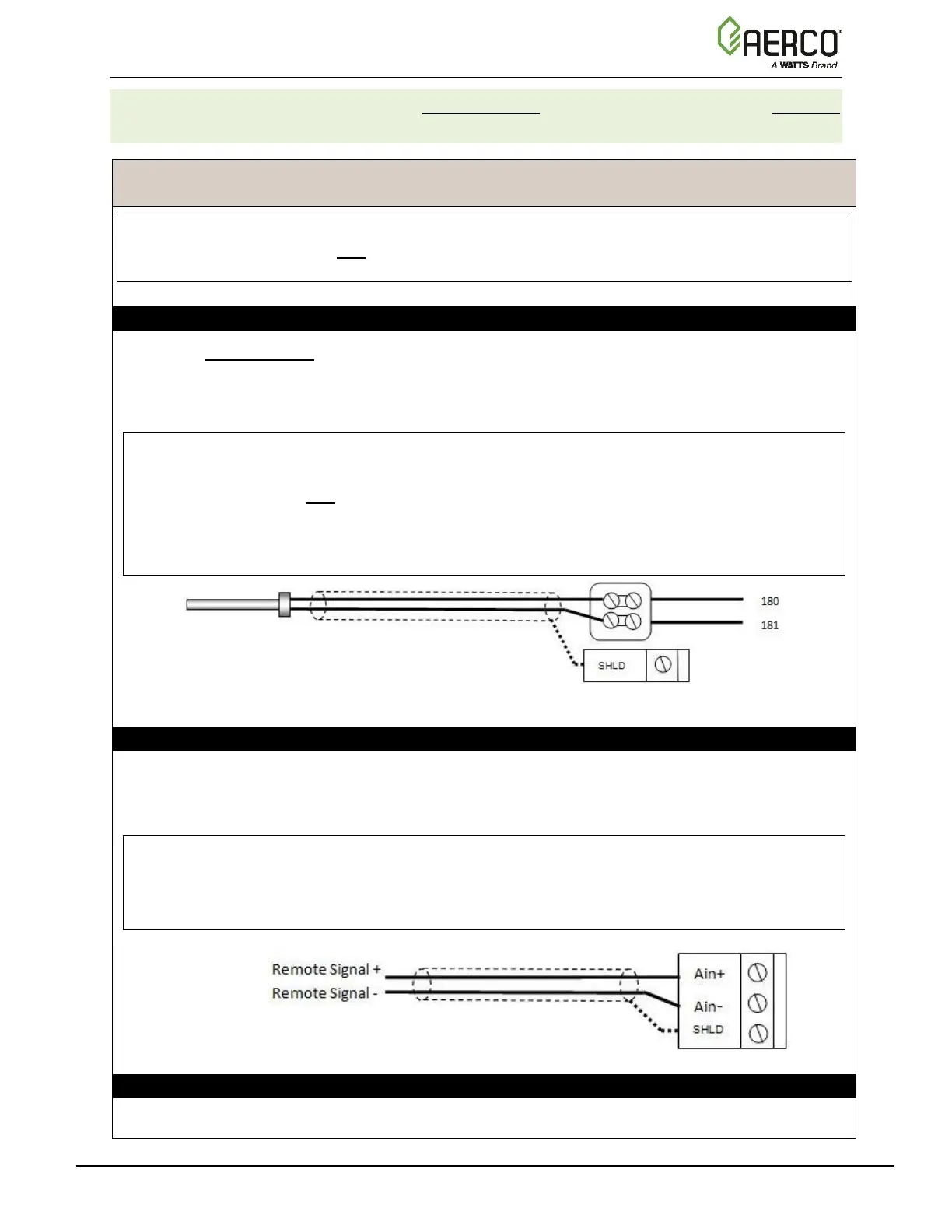

OPTION 5 Step 1: HEADER TEMP SENSOR WIRING – BST MANAGER Unit

1. On the BST Manager unit, connect the Header Temp Sensor to the Feed Forward

(FFWD) terminals on the P-1 Harness via the terminal block labeled Header Temp sensor

on the I/O Board.

2. Ground the shield to any SHLD terminal on the I/O Board.

NOTES:

• The Header Temp Sensor must be installed between 2 and 10 feet (0.61 and 3.1m)

downstream of the last boiler in the plant’s supply water header.

• Shielded pair 18 - 22 AWG cable is recommended for Header Temp Sensor wiring.

There is no polarity to be observed. The ground for the shield is at the SHLD terminal on

the I/O Board. The sensor end of the shield must be left free and ungrounded.

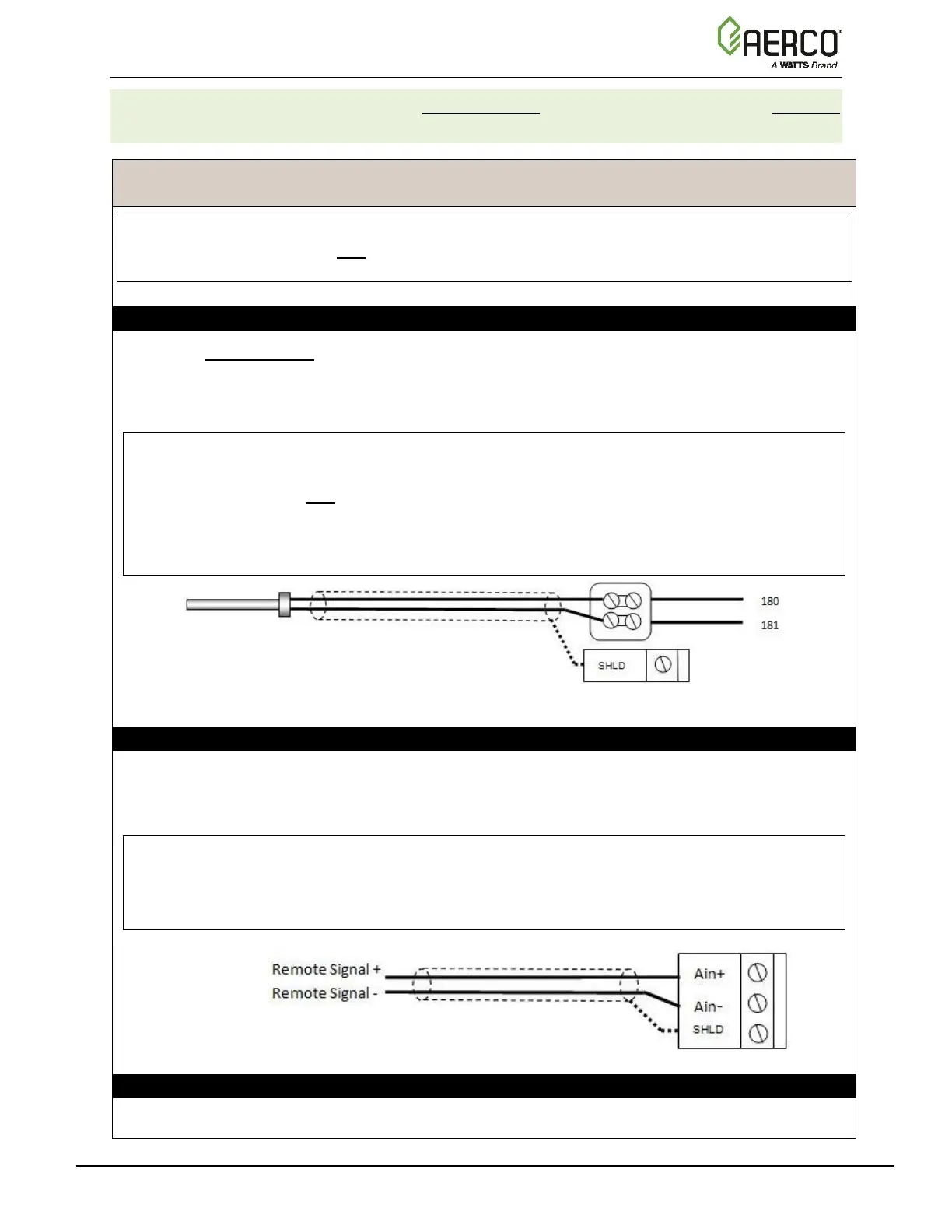

OPTION 5 Step 2: DIRECT WIRED 0-20mA or 4-20mA WIRING – BST MANAGER Unit

1. Connect the 4-20mA or 0-20mA terminals from the Direct Drive source to the Ain+ and Ain-

terminals on the BST Manager’s I/O Board.

2. Connect the shield to any SHLD terminal on the I/O Board.

NOTES:

• Shielded pair 18 - 22 AWG cable is recommended for this connection. Polarity must be

observed.

• The ground for the shield is at the driver signal source.

OPTION 5 Step 3 – DAISY CHAIN WIRING BETWEEN BOILERS

1. Connect the boilers in a daisy chain, as shown below.

Loading...

Loading...