Benchmark with Edge [I]: Operation-Maintenance Manual

SECTION 8 – MAINTENANCE

OMM-0145_D • GF-218 • 11/2/2020 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 131 of 213

SECTION 8. MAINTENANCE

8.1 MAINTENANCE SCHEDULE

All Benchmark boilers require regular routine maintenance to keep up efficiency and reliability.

For best operation and life of the unit, the following routine maintenance procedures should be

performed in the time periods specified in Table 8-1. For a complete inspection check list see

ASME CSD-1 chart.

WARNING!

Prior to servicing, ensure that the following guidelines are strictly observed:

• Follow all Lockout/Tagout protocols in effect at the site.

• Disconnect the AC power supply by turning off the service switch and AC supply circuit

breaker.

• Shut off the gas supply at the manual shut-off valve provided with the unit.

• Allow the unit to cool to a safe water temperature to prevent burning or scalding.

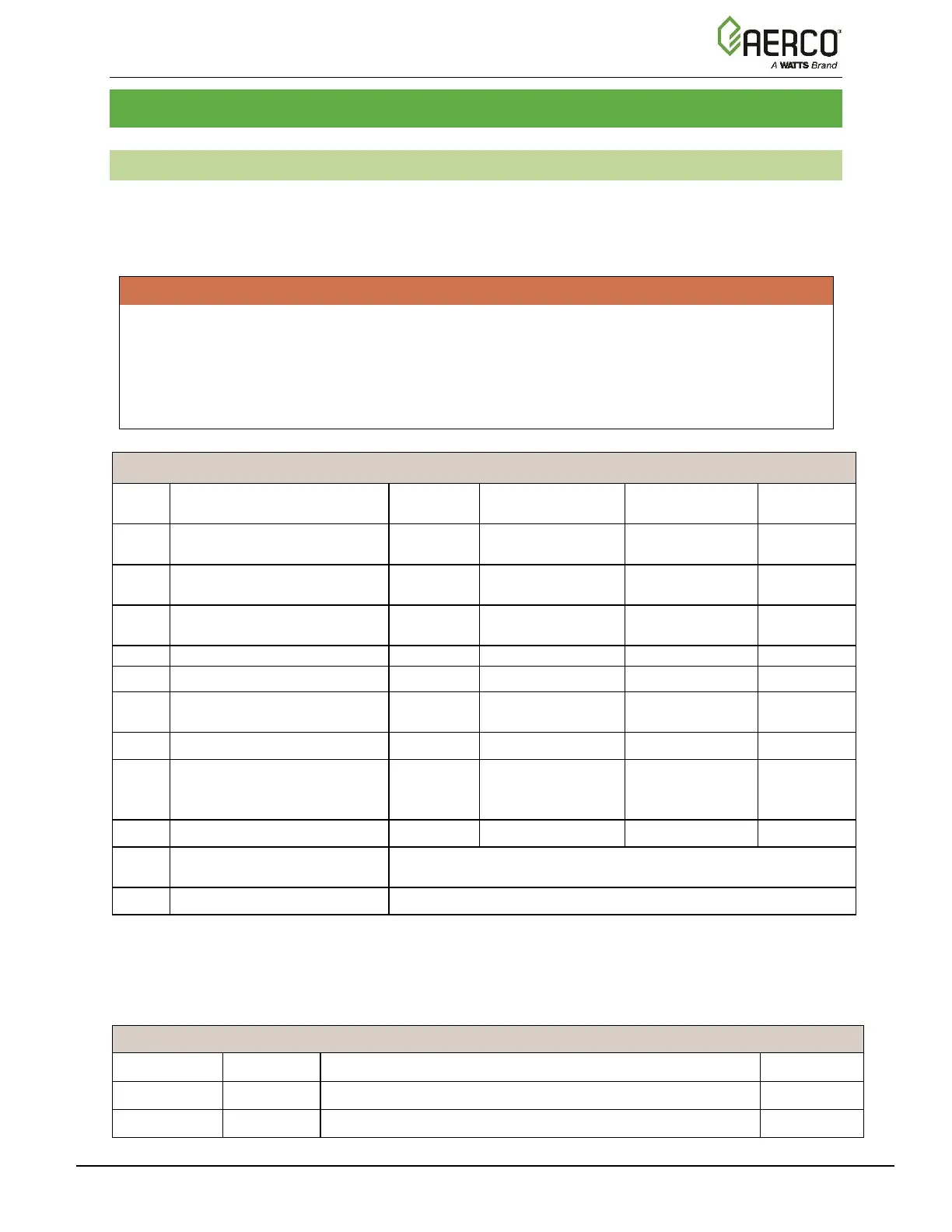

TABLE 8-1: Maintenance Schedule

Igniter-Injector

(BMK750 – 5000N only)

Inspect, replace

if necessary

Pilot Burner

(BMK5000 & 6000 only)

Inspect, replace

if necessary

Inspect, replace

if necessary

Testing of Safety Devices

Inspect, Clean &

Replace

Gaskets

Inspect, Clean

& Replace

Gaskets

Refractory Replacement

(BMK5000-6000 only)

Routine verification of functionality, various schedule

* Only performed after initial 6-month period after initial startup.

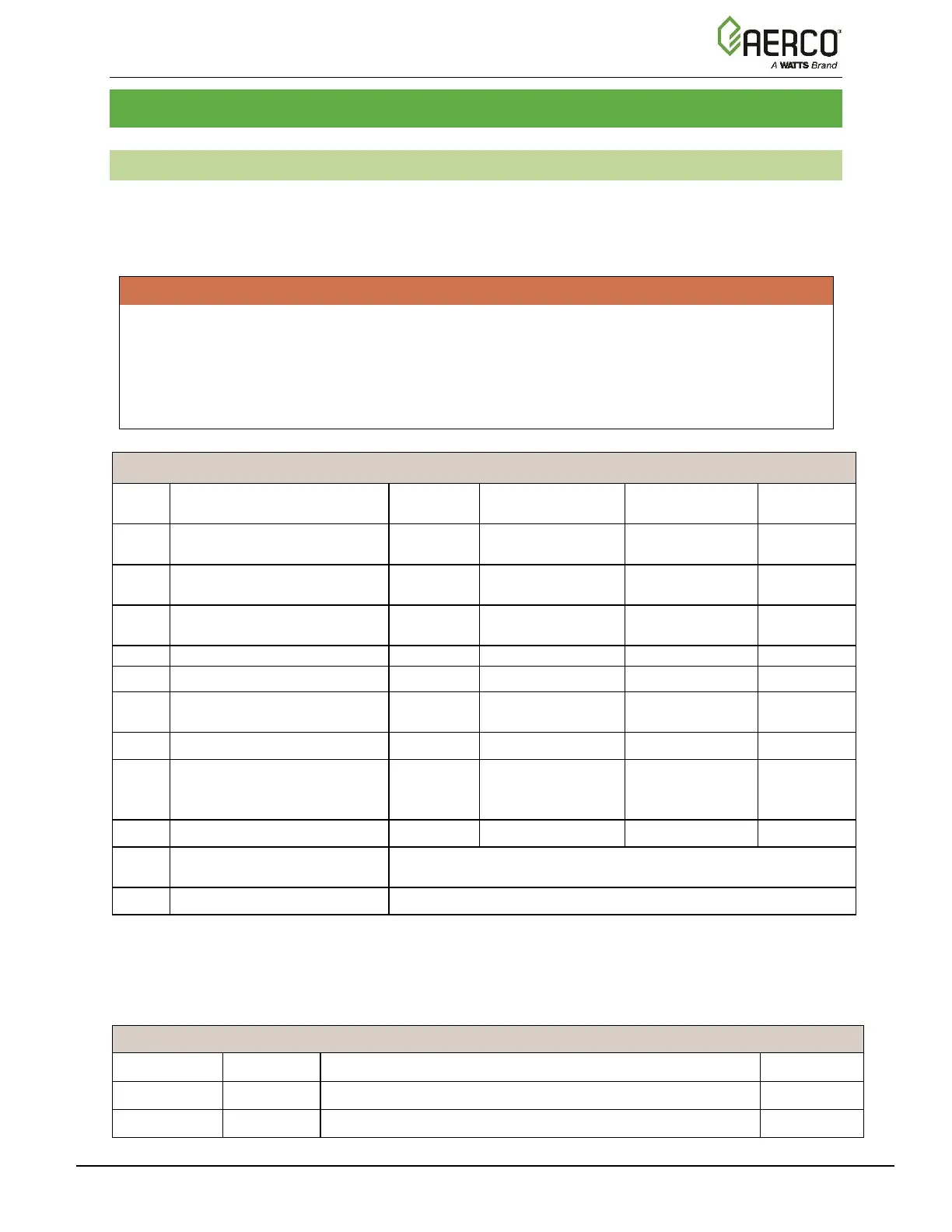

In order to perform the maintenance tasks specified in Table 8-1, the following maintenance kits

are available from AERCO. All kits included a Technical Instruction Document (TID) with

instructions for performing the maintenance.

TABLE 8-2a: 12 Month Maintenance Kits

Ignitor, Flame Rod, Condensate trap O rings

Pilot Burner, Flame Rod & Condensate trap

Loading...

Loading...