Benchmark with Edge [I]: Operation-Maintenance Manual

SECTION 9 – TROUBLESHOOTING

OMM-0145_D • GF-218 • 11/2/2020 Technical Support • (800) 526-0288 • Mon-Fri, 8 am - 5 pm EST Page 158 of 213

9.2 ADDITIONAL FAULTS WITHOUT SPECIFIC FAULT MESSAGES

Refer to Table 9-2 to troubleshoot faults which may occur without a specific fault message being

displayed.

TABLE 9-2: Boiler Troubleshooting with No Fault Message Displayed

1. Clogged/damaged Gas

Injector on Igniter-Injector

(Figure 8-1a through Figure 8-

1c).

1. Disconnect the Staged Ignition Assembly

solenoid from the Gas injector Tube of the

Igniter-Injector (Figure 8-1a through Figure 8-

1c) and inspect Gas Injector to ensure it is not

clogged or damaged.

2. Defective Staged Ignition

Solenoid (Figure 8-1a through

Figure 8-1c).

2. Close the Manual Shutoff Valve. Attempt to

start the unit and listen for a “clicking” sound

that the Staged Ignition Solenoid makes

during Ignition Trial. If “clicking” sound is not

heard after 2 or 3 attempts, replace the

Staged Ignition Solenoid.

1. Gas pressure going into unit is

fluctuating.

1. Stabilize gas pressure going into unit. If

necessary, troubleshoot Building Supply

Regulator.

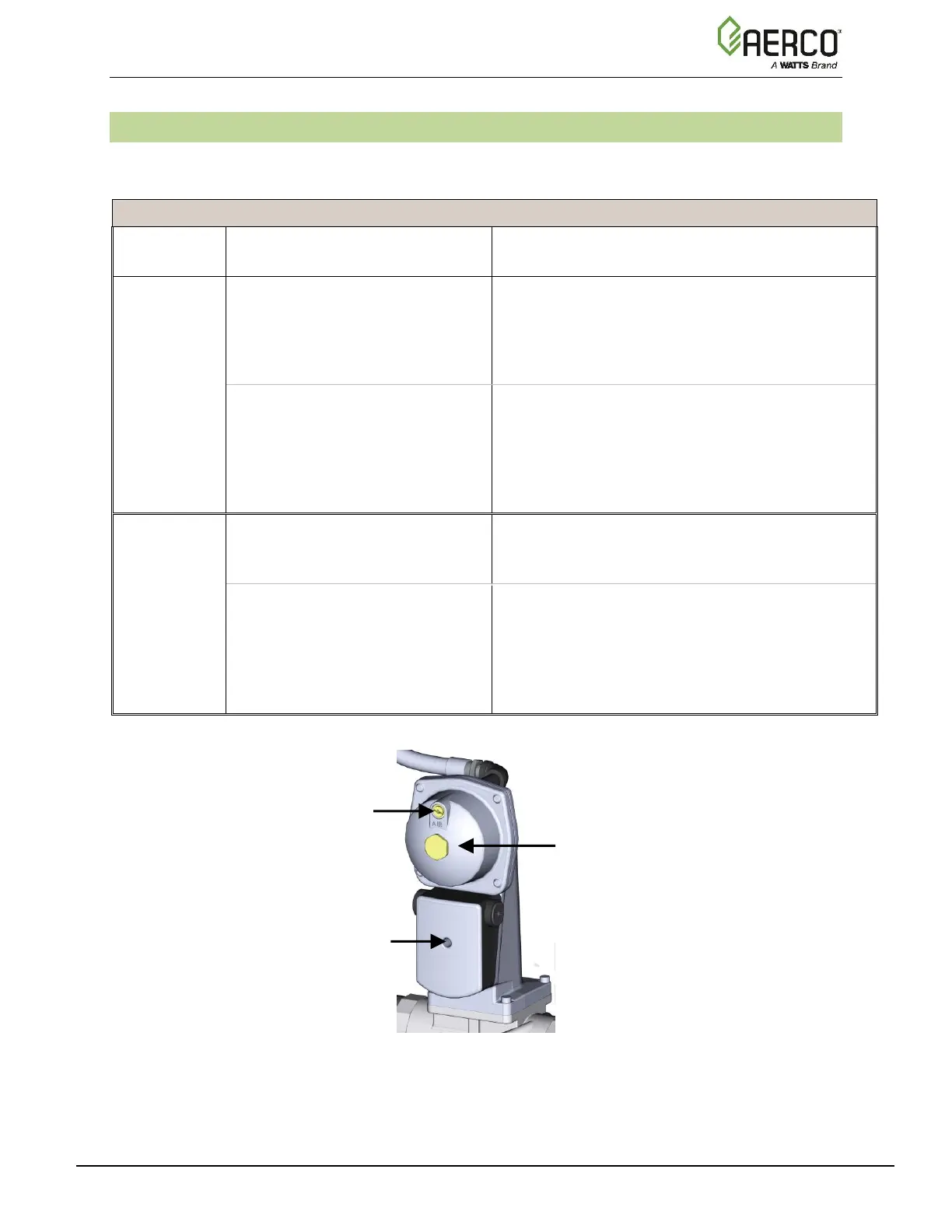

2. Damping Orifice not installed.

2. Check if the gas train is supposed to have a

Damping Orifice, and if so, ensure that it is

installed in the SSOV Actuator, as shown in

Figure 10-1, below. For DBB Gas Trains, the

Damping Orifice is installed in the

downstream SSOV Actuator).

Figure 9-1: SSOV Actuator with Gas Pressure Adjustment (SKP25)

BRASS HEX HEAD

(Remove to access

the Gas Pressure Adjustment

Screw).

Loading...

Loading...