8

MOTOR CONTROL

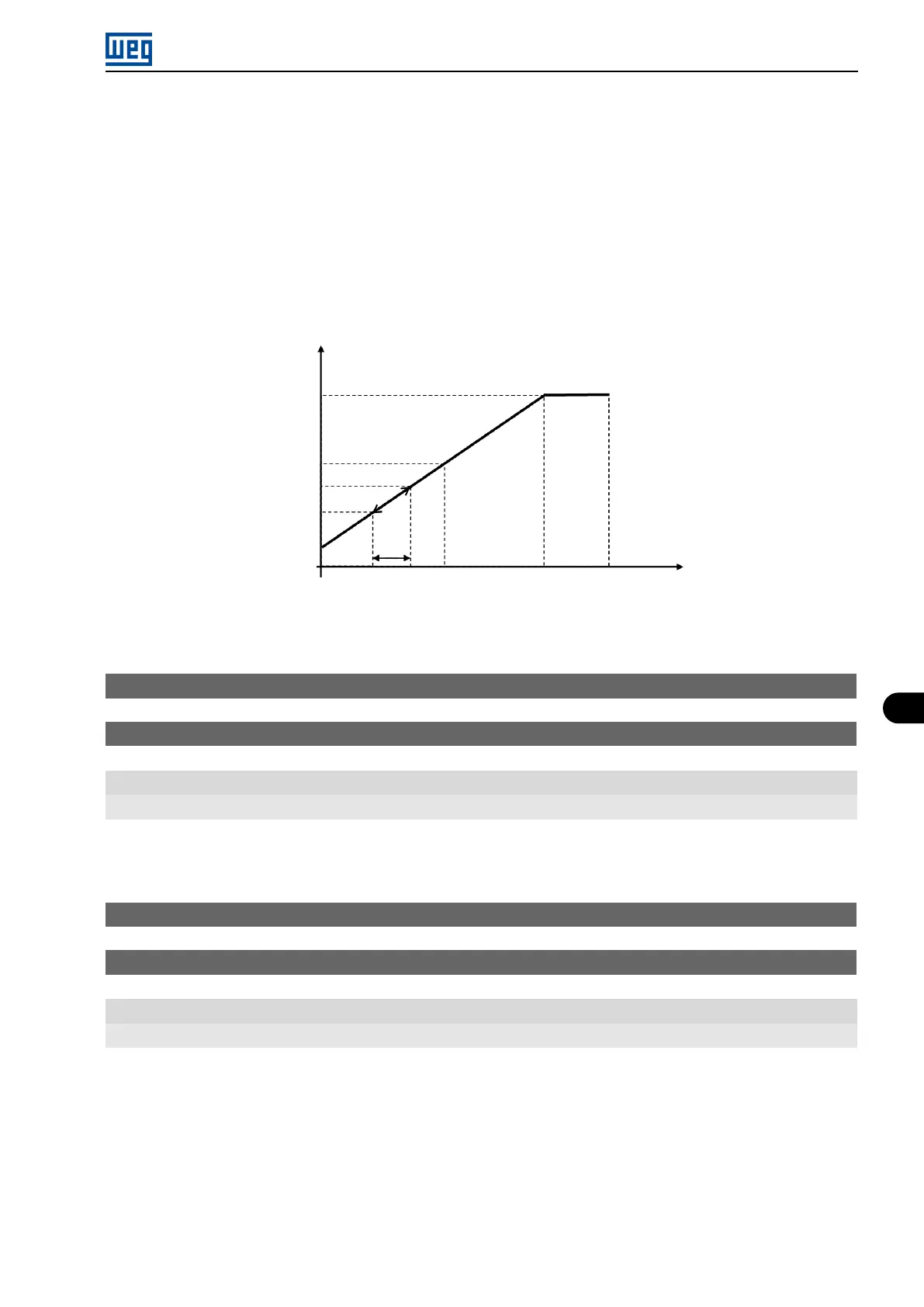

compensates the speed drop due to the application of load on the shaft and, consequently, the slip. Thus, it

increments the output frequency (Δf) considering the increase of the motor active current, as shown in Figure 8.18

on page 8-23. In Figure 8.12 on page 8-19 this compensation is represented in the variable f

Slip

.

The setting in P138 allows regulating with good accuracy the slip compensation by moving the operation point on

the V/f curve, as shown in Figure 8.18 on page 8-23. Once P138 is set, the inverter is able to keep the frequency

constant even with load variations.

Negative values are used in special applications where you wish to reduce the output frequency considering the

increase of the motor current.

Eg.: load distribution in motors driven in parallel.

P134P145P146

P136

P143

P142

∆f

Output

frequency (Hz)

Output

voltage (%)

Figure 8.18: Slip compensation in an operation point of the standar V/f curve

P142 - Maximum Output Voltage

P143 - Intermediate Output Voltage

Range: 0.0 to 100.0 %

Properties: cfg, V/f

Description:

These parameters allow adjusting the inverter V/f curve together with its orderly pairs P145 and P146.

P145 - Field Weakening Speed

P146 - Intermediate Frequency

Range: 0.0 to 400.0 Hz

Properties: cfg, V/f

Description:

These parameters allow adjusting the inverter V/f curve together with its orderly pairs P142 and P143.

The V/f curve can be adjusted in applications where the motor rated voltage is smaller than the power supply

voltage, for example, a power supply of 220 V with motor of 200 V.

The adjustment of the V/f curve is necessary when the motor has a frequency different from 50 Hz or 60 Hz, or when

a quadratic approximation is desired for energy saving in centrifugal pumps and fans, or in special applications:

when a transformer is used between the inverter and the motor or the inverter is used as a power supply.

Micro Mini Drives | 8-23

Loading...

Loading...