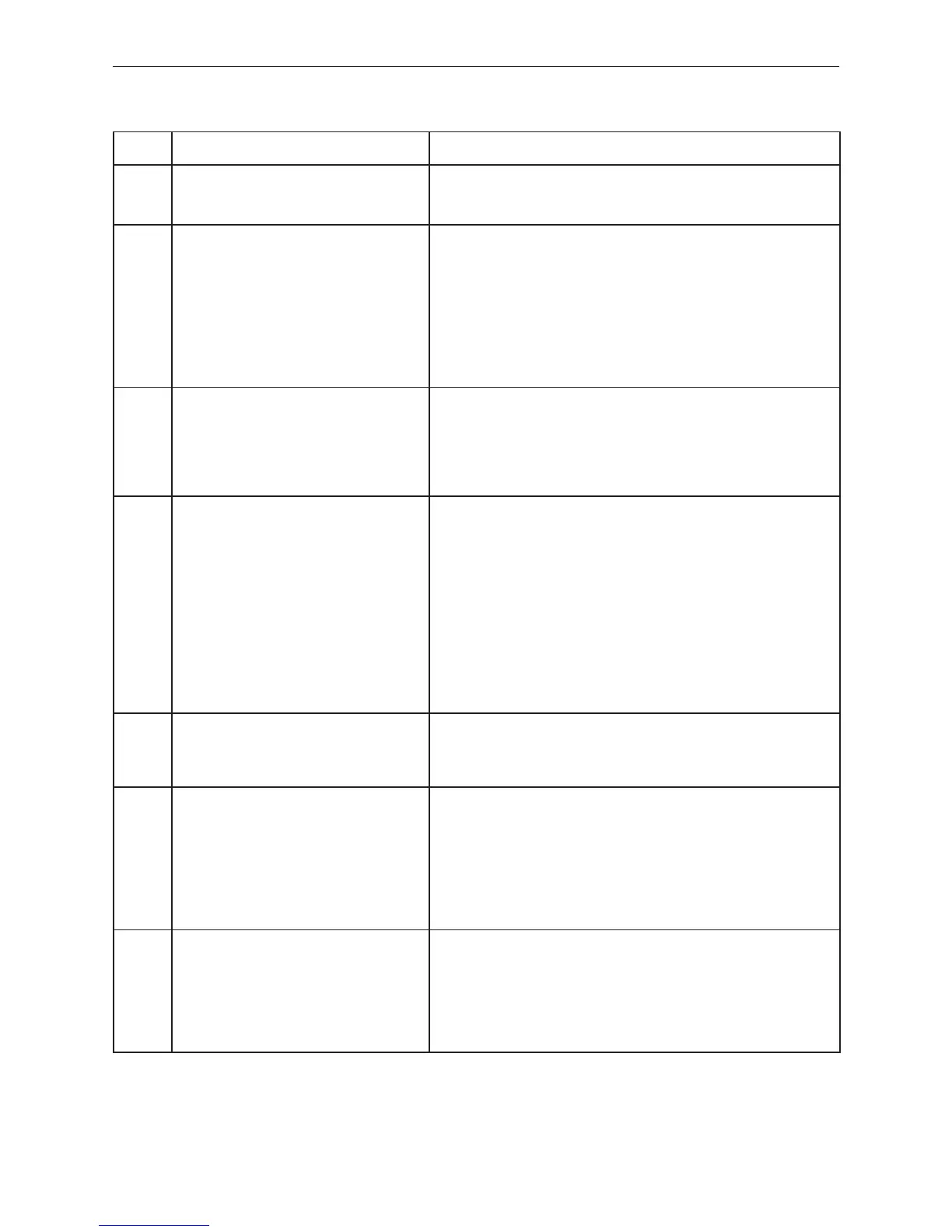

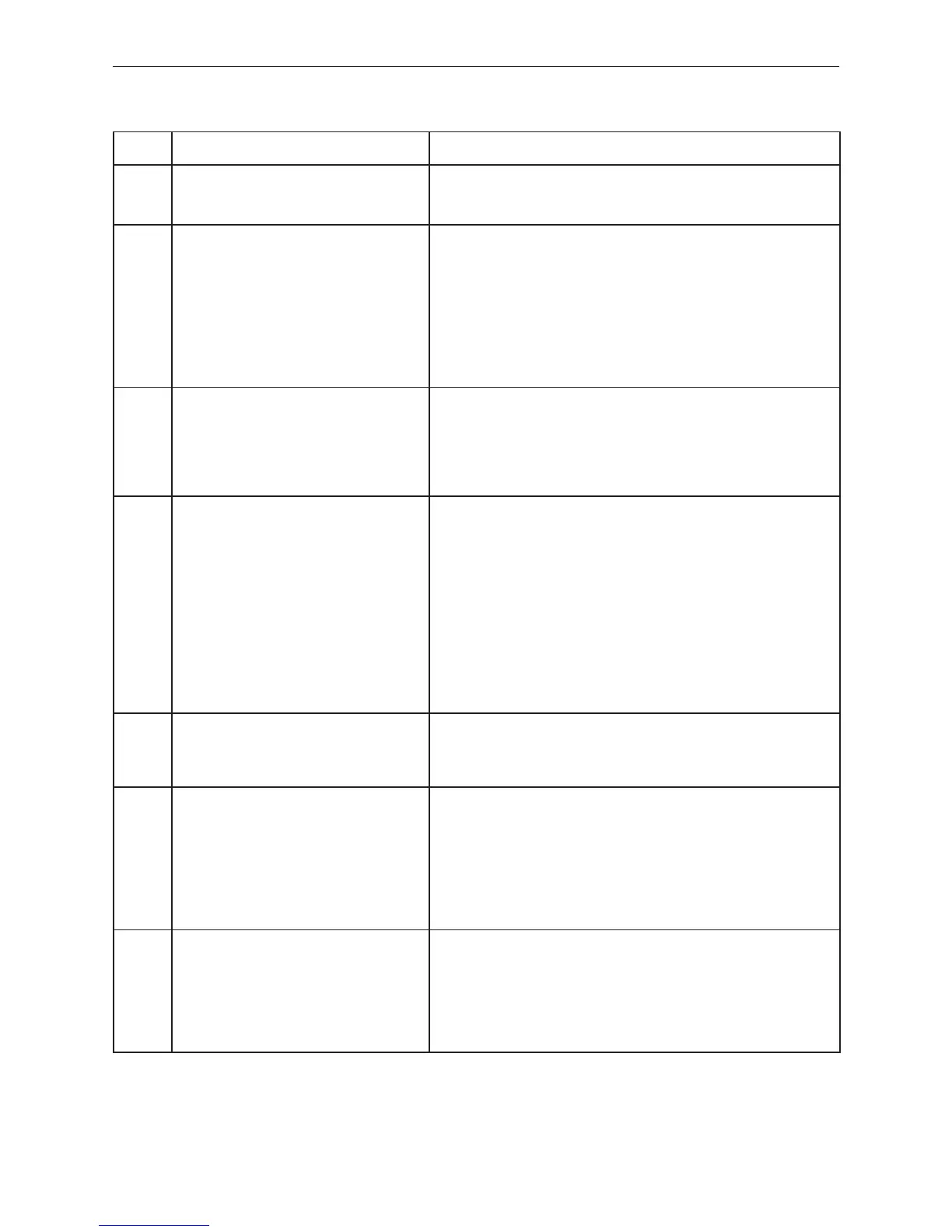

62

4. Troubleshooting

Code Display on InfoWINplus Cause/remedy

FE 206

Monitoring of auger conveyor def.

Press reset.

The boiler is in operation.

Press the Reset button. If the fault reoccurs after a reset, inform Windhager

Customer Service or a heating technician.

FE 238

Feed is not sucking any pellets

Check pellet supply in storage room and feed

hose. Press reset.

No pellet feed is possible. The boiler does not operate.

a) No pellets at the suction probe – Set “probe switching” to “automated”or

select another probe (see section 2.8.1.5). Press the Reset button

b) Feed hose blocked at the cyclone intake or entry to the changeover unit –

clear it. Press the Reset button.

c) Inform Windhager Customer Service or a heating technician.

Emergency operation: Switch off the feed unit (see section 2.8.1.3). Fill the

reserve supply container with pellets by hand, boiler is allowed to continue

operating without feed.

FE 239

Probe switching defective

Check the changeover unit.

Press reset.

No pellet feed is possible. The boiler does not operate.

Press the Reset button. If the fault reoccurs after a reset, inform Windhager

Customer Service or a heating technician.

Emergency operation: Switch off the feed unit (see section 2.8.1.3). Fill the

reserve supply container with pellets by hand, boiler is allowed to continue

operating without feed.

FE 356

Combustion chamber pressure not

stable

Press Reset.

The boiler is in operation.

a) Heating surface cover leaking, check whether this is firmly closed (see

section 3.8), press the Reset button.

b) Combustion chamber and ash door are leaking – check the seal, replace

the seal if necessary, press the reset button.

c) Pressure measuring nipple of combustion chamber pressure switch is

blocked – clear it (see section 3.10.1), press the reset button.

d) Intake air line or induction opening at rear is blocked – clear it and press

the reset button.

e) Exhaust pipe or flue is blocked, clear it and press the reset button.

f) Combustion chamber pressure switch is defective, inform Windhager

Customer Service or a heating technician.

FE 381

Integral fuel hopper empty

Time programme blocking feed. Change enab-

le time in menu/operator level.

Enable time for the feed has been set too short, which means the pellets in

the integral fuel hopper are used up and the feed is blocked.

Extend the enable time for the feed in the “Feed operating mode” menu item

(see section 2.8.1.4) or operate “with start time” or “without time control”.

FE 382

Fill level switch in reserve supply

container defective

Check the switch in the reserve supply

container. Press Reset.

The boiler does not operate.

a) Fill level switch (proximity switch) dirty, remove the dust (see section 3.7),

press the Reset button.

b) Fill level switch (proximity switch) in the reserve supply container defec-

tive – inform Windhager Customer Service or a heating technician.

Emergency operation: Switch off the feed unit (see section 2.8.1.3). Fill the

reserve supply container with pellets by hand, boiler is allowed to continue

operating without feed.

FE 390

Emergency operation! Clean boiler

and burner. Confirm cleaning

Remove ash, clean boiler and burner, confirm

cleaning.

The boiler is in cyclic operation, i.e. has idle times.

a) Boiler and burner must be cleaned or the both ash pans (see Fig. 164)

emptied (see sections 3.3 - 3.6). Once cleaning is complete, press the

Reset button on the InfoWINplus and confirm cleaning on the operator

level (see section 2.8.1.1).

b) Motor or limit switch of ash compactor defective, inform Windhager Cus-

tomer Service or a heating technician.

4.3 FE- messages

Loading...

Loading...