Operation

4002−1/A1

Winterthur Gas & Diesel Ltd.

9/ 15

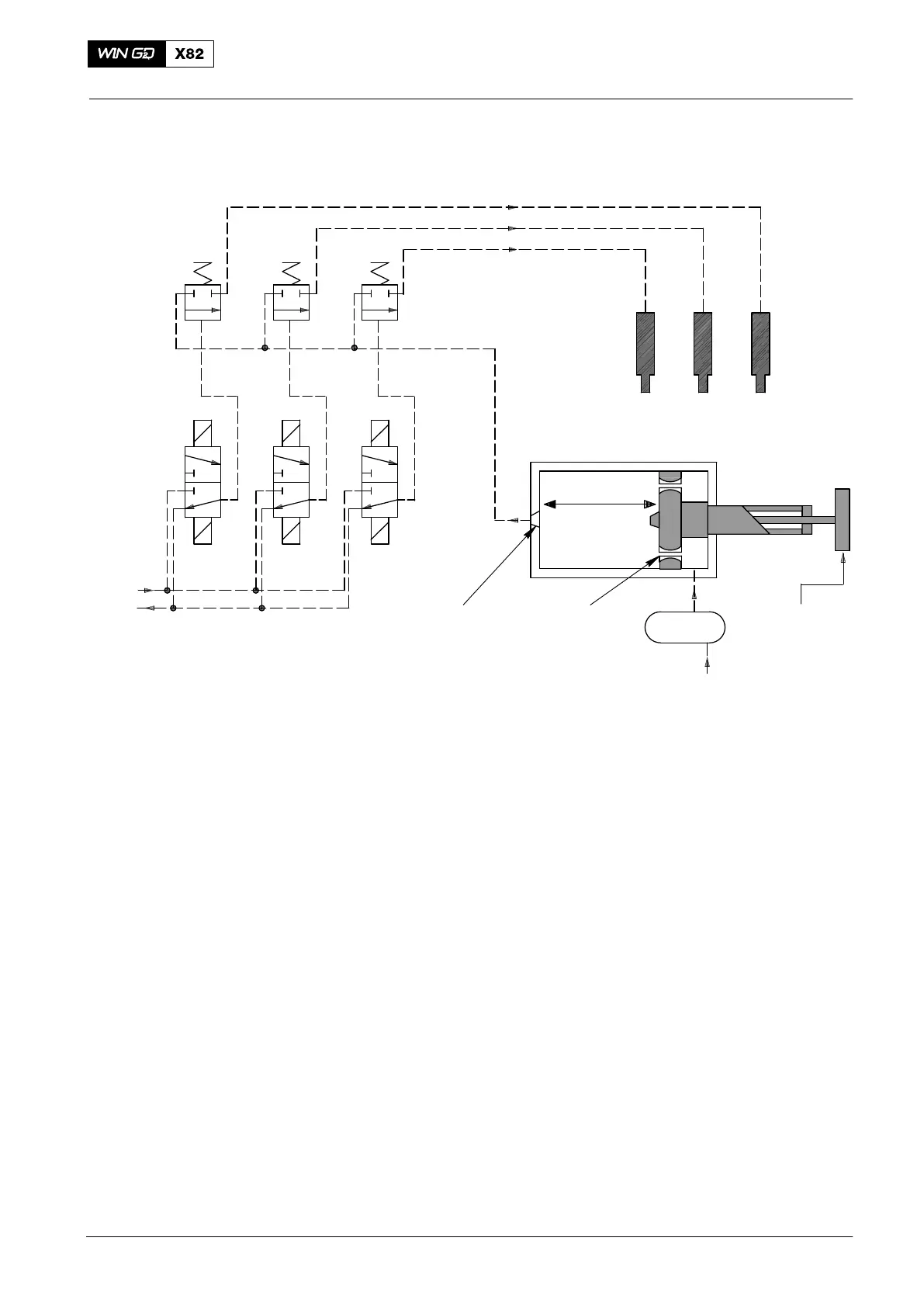

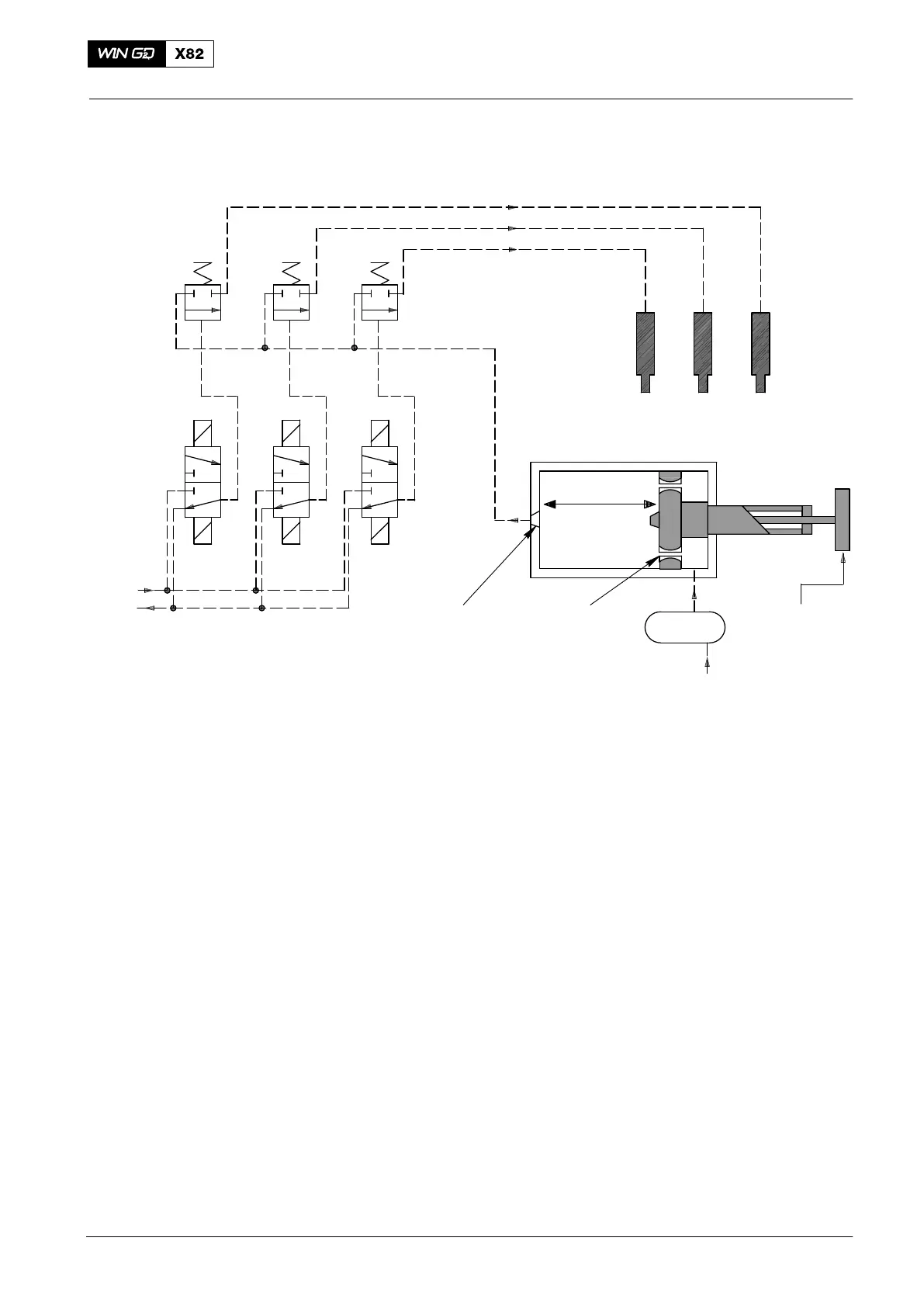

4.3 Fuel Injection Control

All components are shown in

the NO INJECTION position

Fuel Rail

Rail Valves

Fuel

Injection

Valves

Servo

Oil

Injection

Fuel Quantity

Piston

Return

Fuel Quantity

Sensor

Injection

Quantity

Seal for

Emergency

Stop

Injection

Control

Valves

Fuel Quantity

Signal

Fig. 7: Fuel Injection Control

4.3.1 Injection Valve Control Function

All injection valves related to the rail valves of a cylinder are controlled independently,

but with one common feedback signal for the injected fuel quantity.

Usually, all injection valves are activated at the same time. Special operation modes

enable the injection with only one or two injection valves, or with spray intervals

(multi−shot patterns) (see also 0280−1 WECS−9520 Injection control).

To improve the fuel spray at low load, one or two injection valves are cut out

automatically.

The FCM−20 is used to amplify control outputs up to the necessary signal strength for

the rail valves.

4.3.2 Rail Valve ON-time Measurement

The supply to the rail valve is cut off as soon as the valve piston has moved. This is

the measured ON-time and is shown in the remote control.

The measured ON-time gives data about the rail valve condition.

4.3.3 Initial Set-pulse

Because the rail valves are bistable, their initial position is not specified. Thus, at

engine standstill, set-pulses are sent to the rail valves at intervals to get a specified

position.

Engine Control System WECS-9520

2014

Loading...

Loading...