Operation4002−1/A1

Winterthur Gas & Diesel Ltd.

10/ 15

4.3.4 Injection Control

Fuel injection is controlled as follows:

D Data from the crank angle and VIT are used to calculate the injection start.

The rail valves are activated to release the injection.

D The time difference between the injection start signal and the injection start is

known as the injection deadtime. The injection start is sensed when the fuel

quantity piston moves.

D The stroke of the fuel quantity piston gives the injection quantity. The injection is

stopped when the fuel quantity piston is at the calculated stroke.

D The governor calculates the injection quantity, which is related to the control

signal.

D On the subsequent injection cycle, the calculation of the correct injection time

includes the measured injection deadtime.

D The operation of the injection system is monitored at each cycle.

4.3.5 Reverse

For operation of the the engine in ASTERN, the crank angle is mirrored.

4.3.6 Emergency Mode

If the fuel quantity sensor is defective, the control system changes the fuel command

signal from the related FCM−20 into a time period. The related cylinder is then

controlled with timed injection.

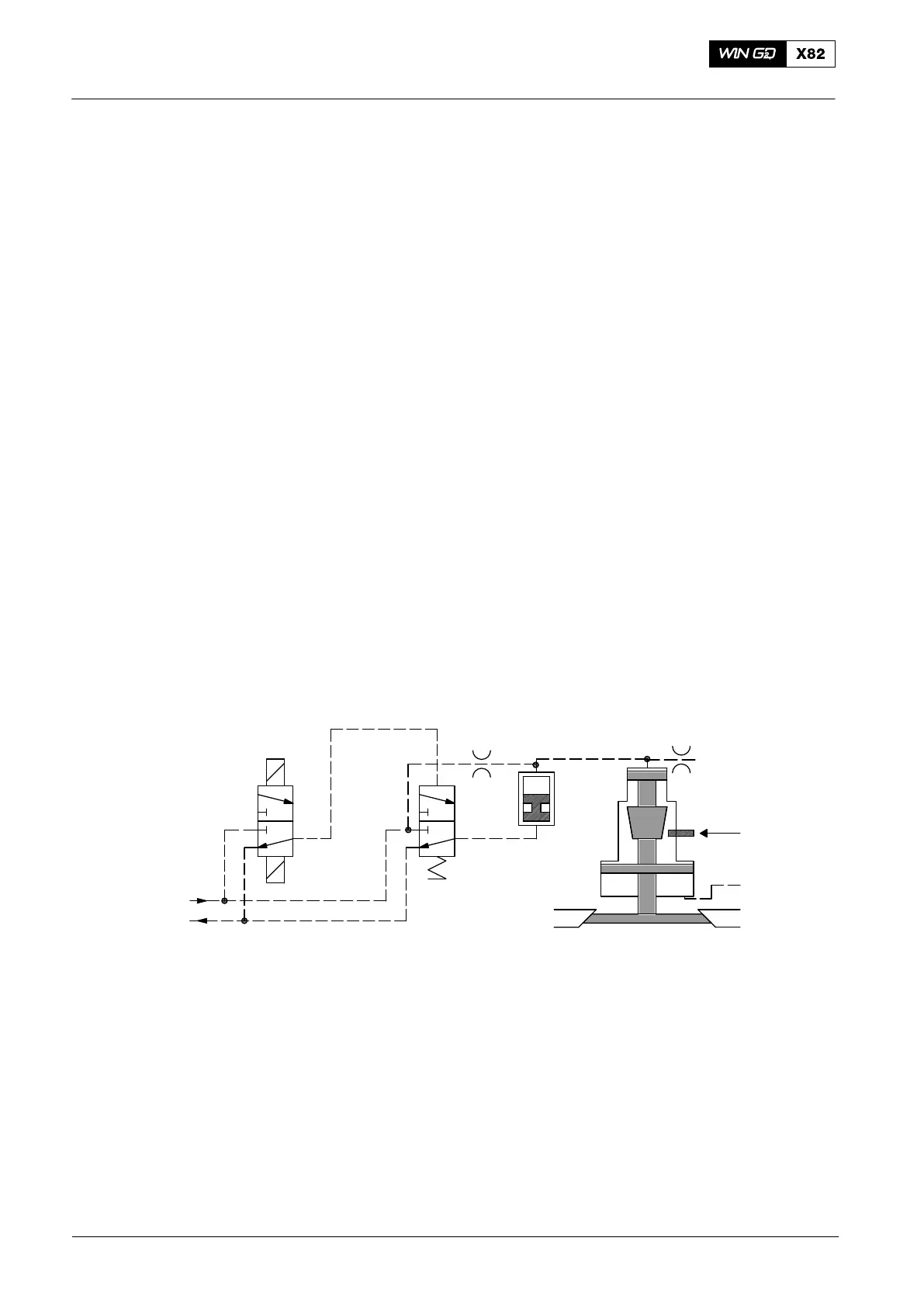

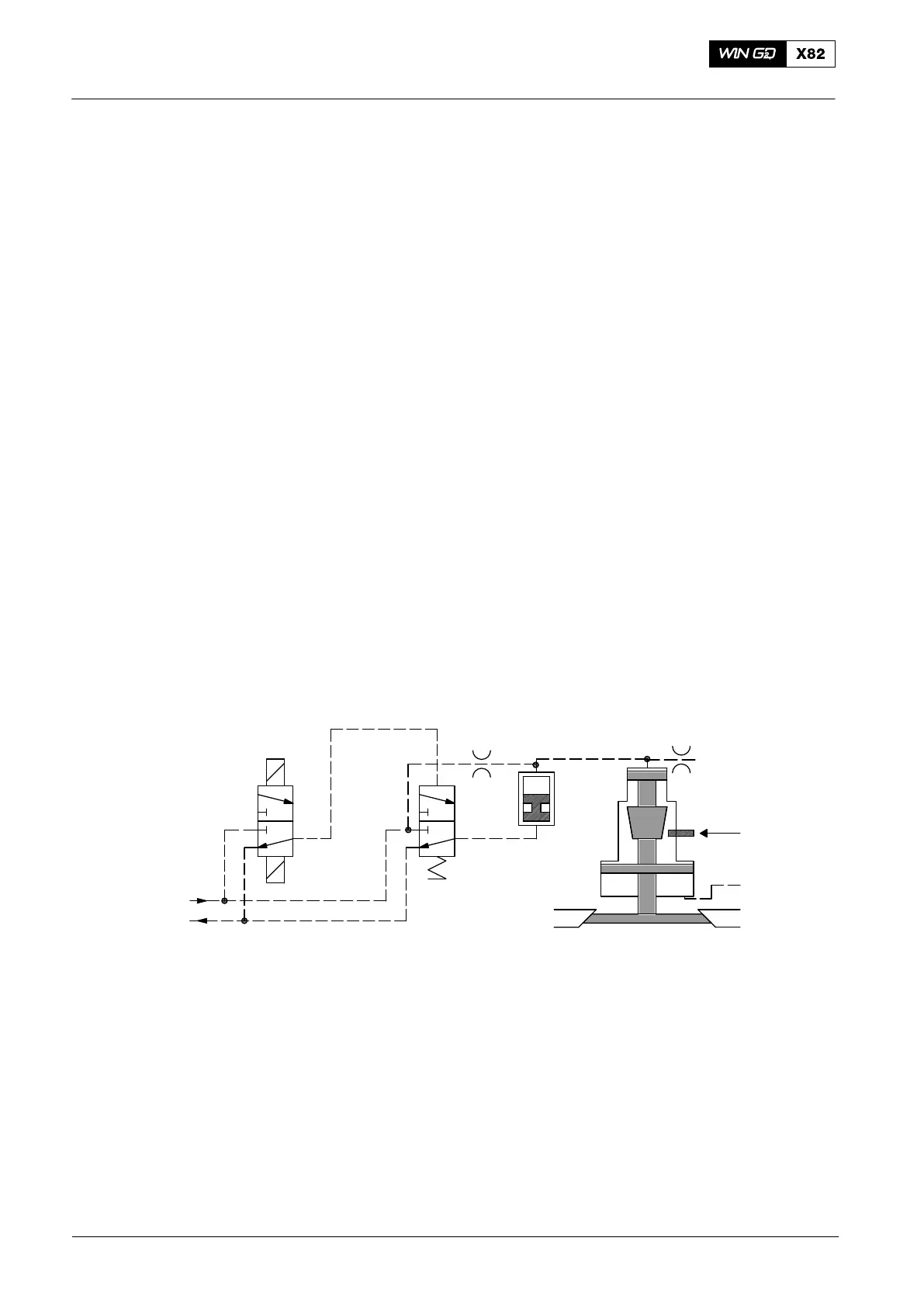

4.4 Exhaust Valve Control

All components shown in

the CLOSED position

Position

Sensor

Air Spring

Air

Rail Valve

OrificeOrifice

Exhaust Valve

Control Unit

Exhaust

Control Valve

Servo

Oil

Fig. 8: Exhaust Valve Control

4.4.1 Exhaust Valve − Function

The exhaust valve opens and closes once each full turn of the crankshaft. The valve

stroke sensor measures the exhaust valve movement.

The FCM−20 amplifies the control outputs up to the necessary signals for the rail

valves.

4.4.2 Rail Valve ON-time Measurement

The time between the start signal and the valve piston movement is measured, then

shown in the remote control.

Engine Control System WECS-9520

2014

Loading...

Loading...