Operation

6735−1/A1

Winterthur Gas & Diesel Ltd.

3/ 4

2.1 Open and Close Phases

When the outside air temperature decreases below the values given in Table 1, the

solenoid valve (8, Fig. 2) energizes. The scavenge air pressure flows through the

pressure reducing valve (9), then through the non-return valve (16) to the pressure

space (PS). The pressure in the pressure space (PS) decreases.

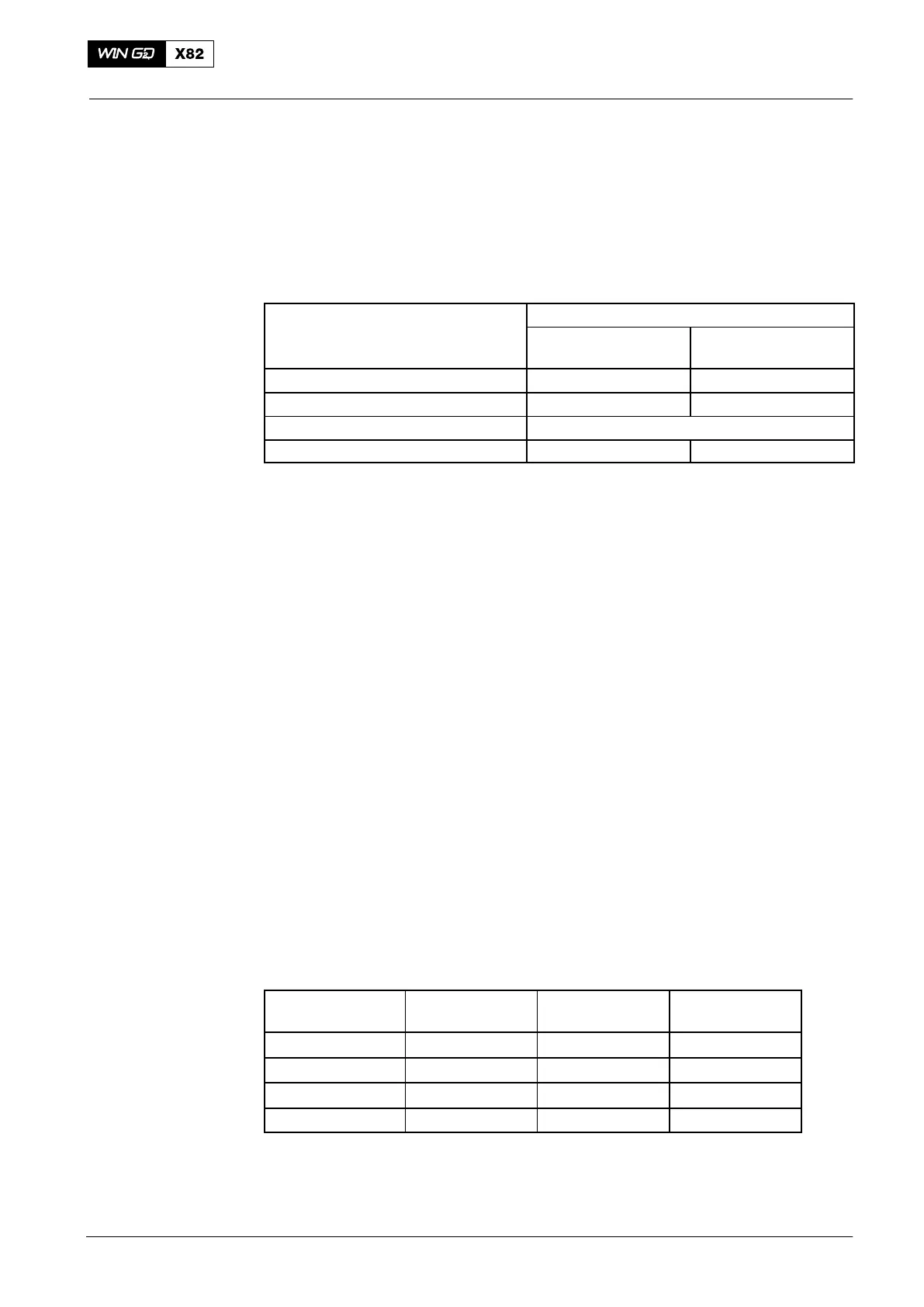

Table 1: Temperatures and Pressures

External Temperatures

Engine without

WHR

Engine with WHR

Solenoid valve energizes below

+5° C −5° C

Solenoid valve de−energizes above

+10° C 0° C

Pressures

Pressure reducing valve adjusted to 0.75 bar 0.7 bar

Note: WHR (Waste Heat Recovery System)

The pressure in the pressure space (PS) can now be less than the pressure in the

area (SP). Then the pressure in the area (SP) moves the piston (4) against the force

of the compression spring (5) and the waste gate valve opens. Scavenge air then

flows through the silencer into the engine room.

The temperature sensor (17) (TE3991C) measures the outside air temperature to

energize/ de-energize the solenoid valve (8).

3. Adjustments

3.1 Valve Stroke Check

This task is only necessary after faults, overhauls or when the waste gate valve was

replaced.

Do this check when the engine has stopped, or when the engine operates at a load of

75% or less at the usual suction temperatures (more than +5_C).

1) Remove and discard the lockwire from the adjustment screw (6).

2) Loosen the locknut (7).

3) Turn the adjustment screw (6) fully clockwise to its limit.

4) Adjust the nominal piston stroke with reference to Table 2 (one full turn of the

adjustment screw (6) is equal to a piston movement of 1.5 mm).

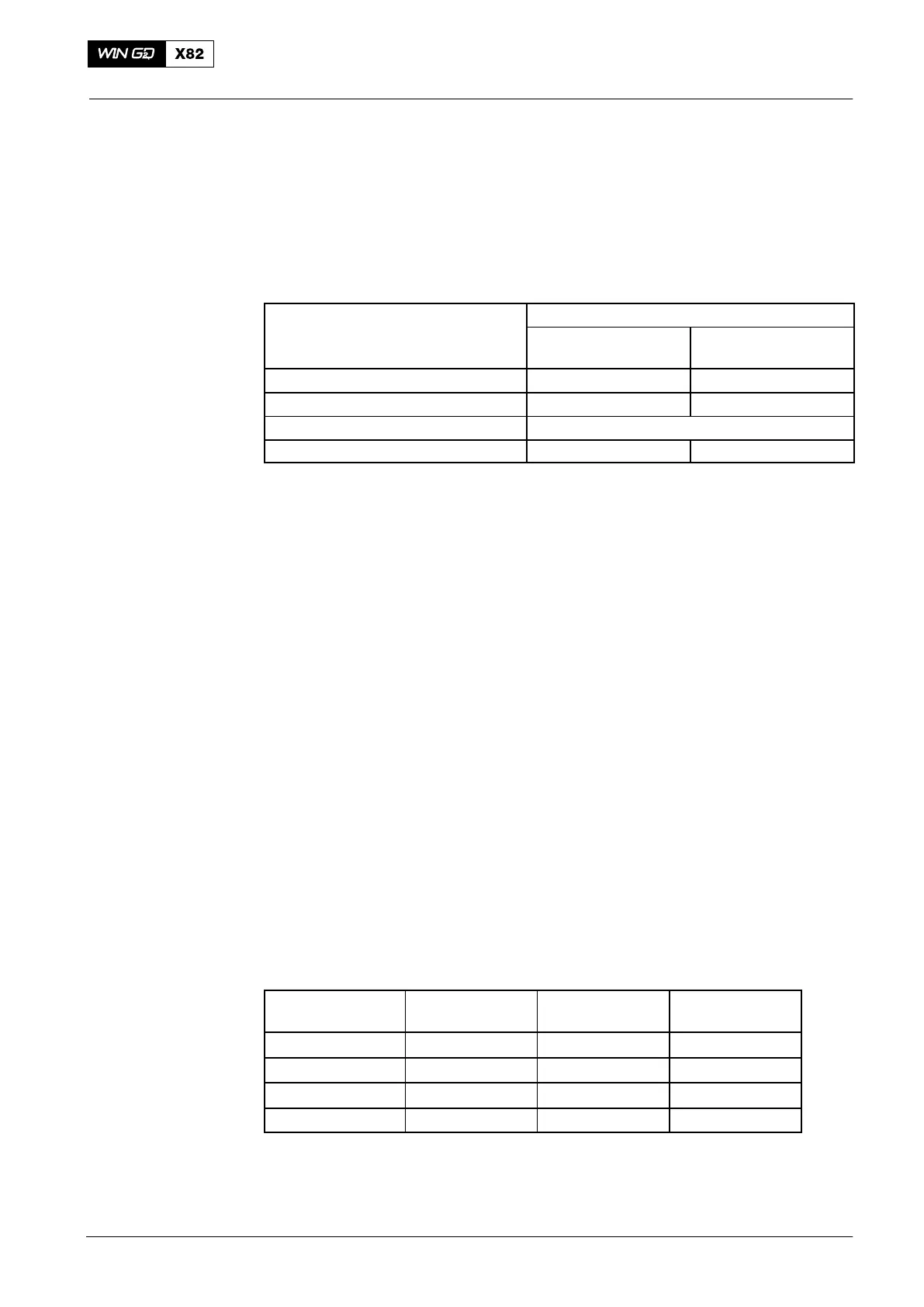

Table 2: Valve Stroke

Number of

Cylinders

Number of

Waste Gates

Piston Stroke

(mm)

Number of

Turns

6 1 12.0 8

7 1 13.5 9

8 1 16.5 11

9 1 18.0 12

5) Tighten the locknut (7).

6) Lock the adjustment screw (6) in position with lockwire.

2017−08

Scavenge Air Waste Gate

Loading...

Loading...