5-3

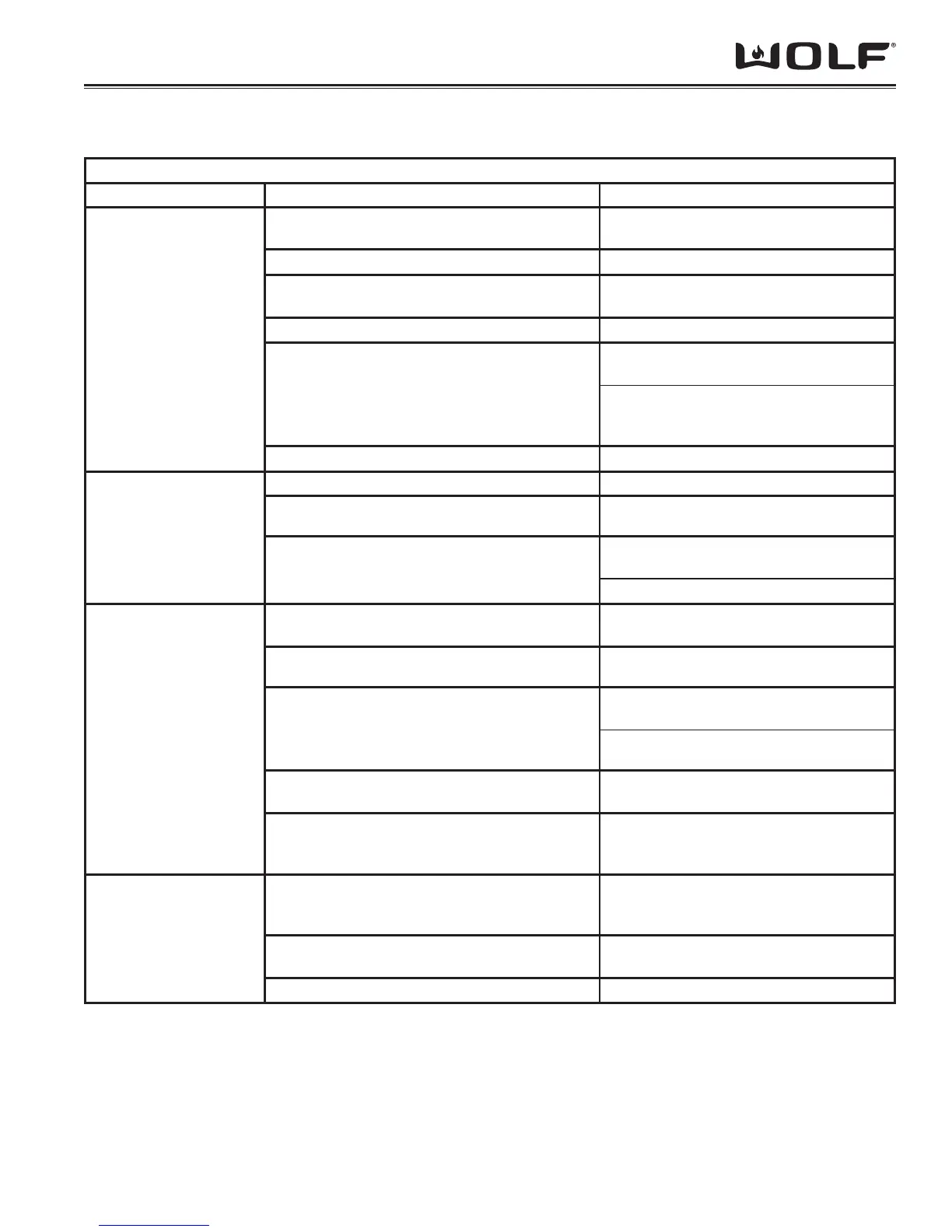

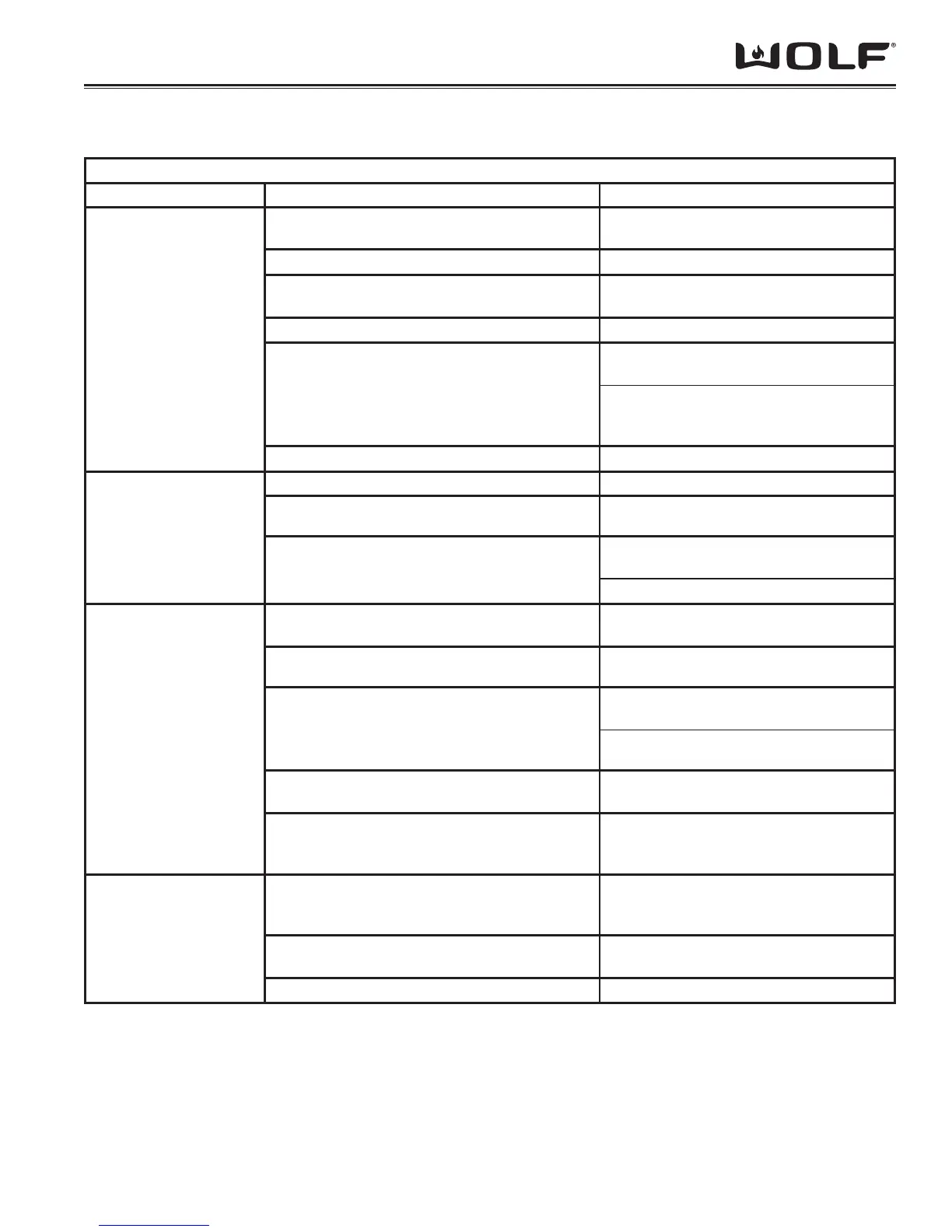

Troubleshooting CT Hoods and DD Ventilation

VENTILATION TROUBLESHOOTING

CTWH & IH

Symptom Diagnostic Test Resolution

Lights do not light

Check for incoming power to hood at CN2

(Black & White)

If no voltage reset power supply breaker

Check Bulbs for continuity Replace if defective

“Light” LED illuminated on touch control with

light selected.

If not illuminated replace Touch Control

Check Lighting Fuse for continuity Replace if defective

Check for 120 VAC at CN3 (plugged in) with

lights turned on

If no voltage replace Control Board

If voltage present - check for 120 VAC

at Lighting Transformer - if no voltage

change harness

Check for 12 VAC at Lighting Transformer If no 12 VAC replace transformer

Blower does not shut off Unit is above 174°F (79°C) Allow unit to cool down.

Remote blower wired improperly See Wiring Section for proper connection

Check continuity of Heat Sentry w/CN5

disconnected from Control Board.

If there is continuity replace Heat Sentry

If no continuity Replace Control Board

Blower does not run

If internal blower - make sure blower is plugged

in.

Plug blower in.

Remote blower wired improperly See Wiring Section for proper connection.

Disconnect CN4 and check for motor continuity

and ground

If no continuity verify wiring correct and no

broken wires

Replace motor if it is open or grounded

LED is not illuminated on touch control of

selected speed

Change touch control

Check for appropriate voltage at CN4 for

selected speed w/CN4 plugged in. (see Tech

Data Section)

Improper or no voltage: replace Control

Board

Hood does not move

enough air

Correct Ducting installation

See Ventilation Specs for proper duct size

- verify entire run is correct including wall/

roof cap

Make-up air may be required for adequate

operation

Open a window and if unit draws more

then make-up air is inadequate

Incorrect blower installed See Ventilation Specifi cations

Loading...

Loading...