Fault finding and diagnosis

Greenstar 2000 – 6 721 820 552 (2021/02)

74

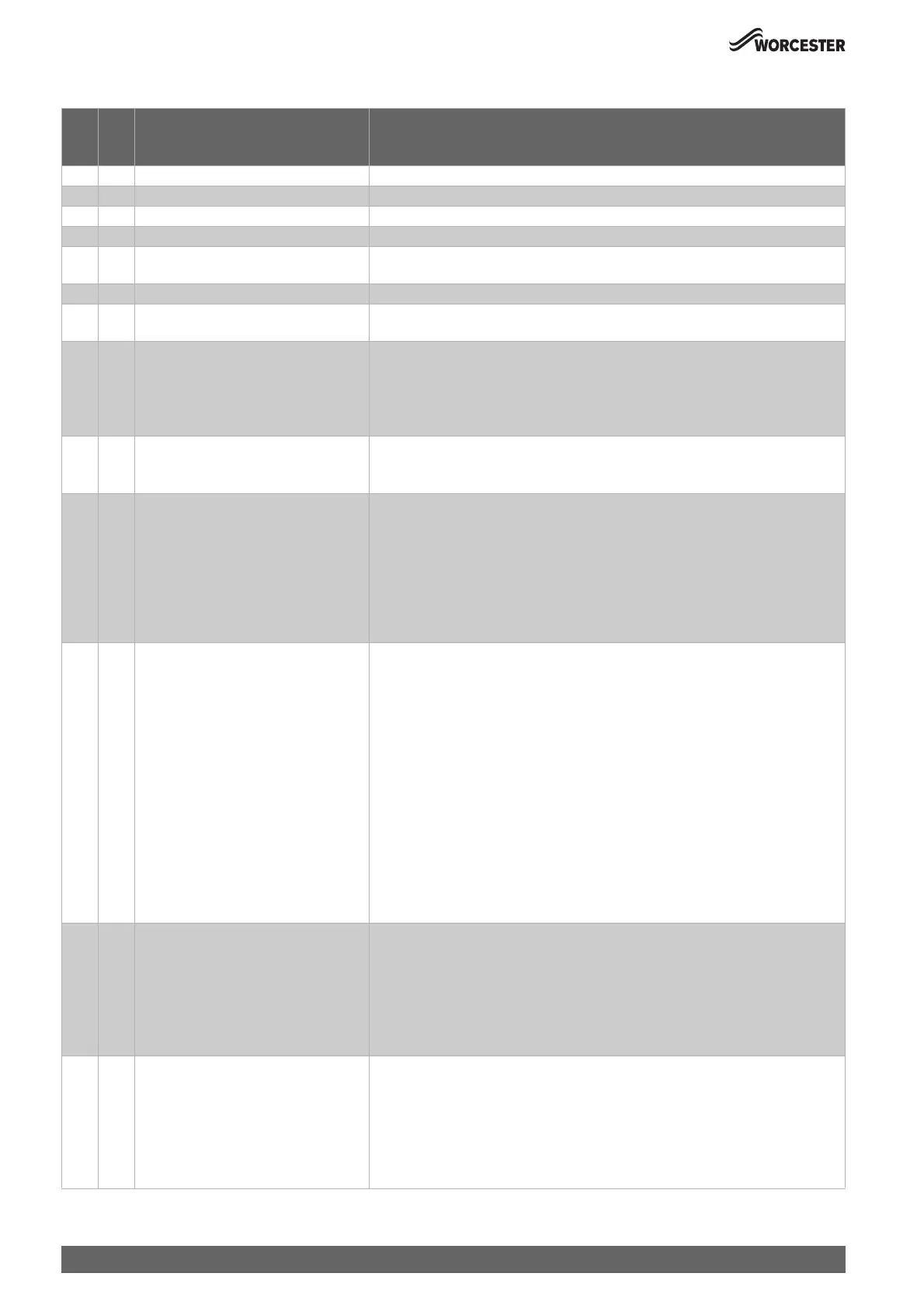

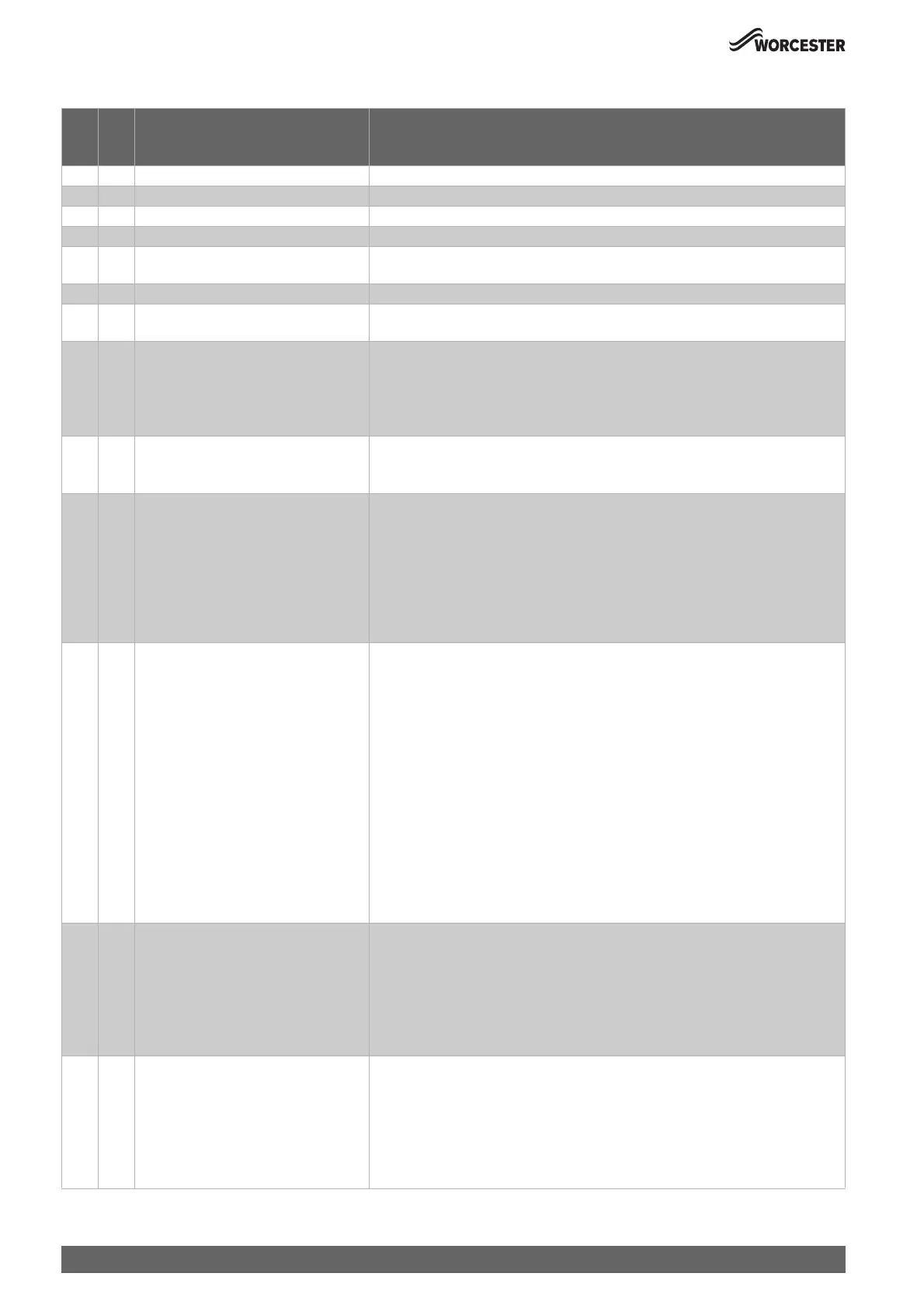

11.2 Fault code table

Fault

code

Fault

category

Description Remedy

200 O Boiler in heating mode Operating message, is not a fault.

201 O Boiler in hot water mode Operating message, is not a fault.

202 O Boiler in anti-cycle mode Operating message, is not a fault.

203 O Boiler in standby, no heat energy demand Operating message, is not a fault.

204 O Current prim. water temp. higher than set

val.

The actual boiler water temperature is higher than the target boiler water temperature. The

boiler is switched off.

208 O Chimney sweep demand Operating message, is not a fault.

212 – Rise in temp. of safety or heating flow

sensor too fast

Open the shut-off valves.

214 V Fan shut down during safety time ▶ Reset the appliance.

▶ Create a heat demand; check if the boiler fires up.

▶ Check the voltage to the fan and the continuity of the fan harness.

▶ Check the power modulation on the fan.

▶ PCB may be defective.

215 V Fan shut down during safety time ▶ Replace fan.

▶ Mains voltage must correspond to the default value.

▶ Check PCB and fan harness, replace if necessary.

224 B/V Safety temp. limiter has tripped ▶ Check if lead is disconnected from the safety temperature limiter.

▶ Check the high limit of the safety temperature limiter and the harness for continuity.

▶ Check the flow temperature to confirm actual temperature (may have tripped out at

lower temperature, leading to safety temperature limiter fault)

▶ Check the system pressure and top up as required.

▶ Check if air is trapped in the system and in the boiler.

▶ Pump seized/not running: check the pump for failure or blockage.

▶ Check if blockage/restriction within boiler/pipe work restricting the flow.

227 B/V No flame signal after ignition Tip: Check the ceramic insulator is not damaged, this can cause the spark to earth, twist

and pull the ceramic insulator to ensure it is not broken.

▶ Check the gas supply to property and the inlet on the gas valve.

▶ Check the low pressure when the gas valve opens.

▶ Gas valve failing to open: check for voltage to the valve and for possible blockage on

inlet filter of the gas valve.

▶ Obstruction in the air intake to the fan leading to incorrect CO

2

ratio. Diaphragm is

damaged or stuck.

▶ Condensate trap is blocked or restricted. Condensate pipe is frozen.

▶ Flue is blocked or restricted.

▶ Heat exchanger is blocked or restricted.

▶ Check the burner for damage.

▶ Check the spark electrode or the lead failure.

▶ Check the flame sense or the lead failure.

▶ Check the rectification ground (black wire to heat exchanger).

228 V Flame signal without flame present Tip: Check the ceramic insulator is not damaged, this can cause the spark to earth, twist

and pull the ceramic insulator to ensure it is not broken.

▶ Check the flame sense and the lead and replace if required.

▶ Check the earth tags on the boiler and on the electrodes.

▶ Check the operation of the siphon and no water collecting in the sump.

▶ Replace the air and/or gas ratio control valve.

▶ Replace the control unit and/or burner control unit.

229 B Flame failed during burner operation Tip: Check the ceramic insulator is not damaged, this can cause the spark to earth, twist

and pull the ceramic insulator to ensure it is not broken.

▶ Check the gas supply to the property and check the working pressure on the gas valve

inlet.

▶ Check the gas-air ratio.

▶ Check the ionisation electrode and the harness for damage or contamination.

▶ LPG: Sufficient gas in the tank or recently refilled?

Loading...

Loading...