6D93G11

5-46

1

2

3

4

5

6

7

8

9

6. Remove the connecting rod cap and

measure the width of the compressed

Plastigauge (PG-1) on each crankpin.

Replace the connecting rod bearing if out

of specification.

Selecting the connecting rod bearing

NOTE:

Use a metric gauge in this procedure.

1. When replacing the connecting rod bear-

ing, select the suitable bearing as fol-

lows.

2. Measure the connecting rod big end

inside diameter

a

.

NOTE:

Reuse the removed connecting rod bolts.

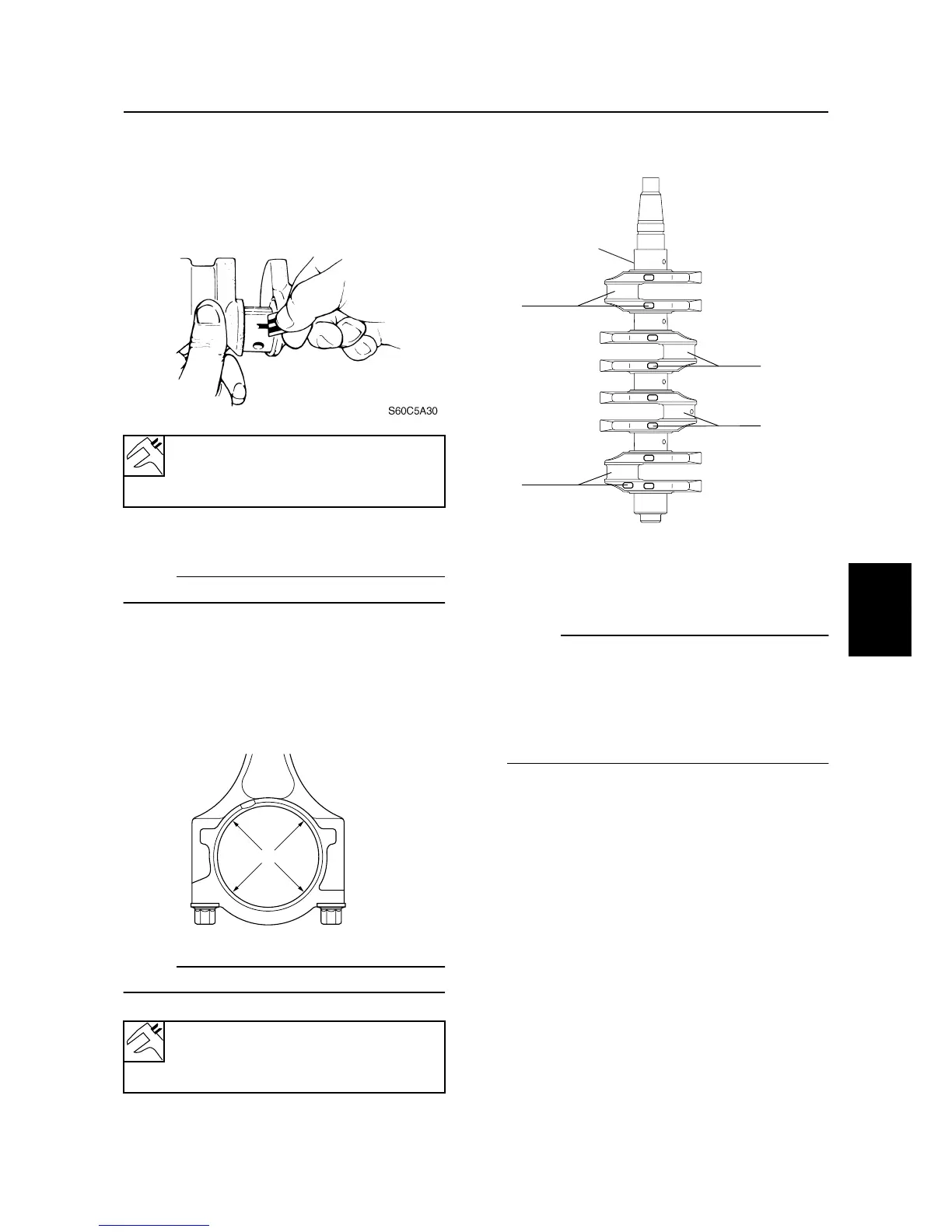

3. Check the crankpin mark on the crank-

shaft

1

.

4. Subtract the crankpin diameters (#1–#4)

from the connecting rod big end inside

diameters (#1–#4).

NOTE:

The crankpin diameters (#1–#4) can be

determined by the stamped value as

described below.

Crankpin diameter = 43.900 + (stamped

value/1,000)

Example: #1 = 92

→

43.992

Crankpin oil clearance:

0.024–0.044 mm

(0.0009–0.0017 in)

Connecting rod big end inside

diameter

a

:

47.025–47.045 mm

S60C5980

a

(#1)

(#2)

(#3)

S6D85670

(#4)

1

Cylinder block

Loading...

Loading...