FUEL SYSTEM

Fuel Feed Pump Components and Functions

6-30 6LY3 Service Manual

© 2007 Yanmar Marine International

Fuel Feed Pump Specifications

Disassembling the Fuel Feed Pump

1. Remove the piston spring plug and pull out the

piston and piston spring.

2. Remove the retaining ring and pull out the roller

guide, roller pin and roller.

3. Pull out the inter-spindle.

4. Remove the priming pump.

5. Remove the discharge valve spring plug.

Remove the valve and spring.

6. Remove all O-rings.

Inspecting the Fuel Feed Pump

1. Block the priming pump with your finger and

check whether the pressed-in piston returns by

spring force.

2. If the piston returns, the piston does not have

enough negative (-) pressure. Always replace

the priming pump as a complete set.

3. Check the piston spring for cuts, cracks, uneven

wear and rust.

4. Replace the piston, inter-spindle or tappet if

extremely worn.

5. Check the contact surface of the valve and

valve seat for defects.

6. When there is play in a valve seat which has

been sealed into the feed pump body, replace

the entire pump body. NOTICE: Play in the

valve seat hinders the opening and closing of

the valve, causing insufficient fuel supply and

abnormal wear of the tappets and camshaft.

Assembling the Fuel Feed Pump

1. Position the discharge valve and spring in the

fuel feed pump housing. Lubricate and install a

new O-ring on the discharge valve plug. Install

the discharge valve plug.

2. Lubricate and install a new O-ring on the

priming pump. Install the priming pump.

3. Position the piston and piston spring in the fuel

feed pump housing. Lubricate and install a new

O-ring on the piston spring plug. Install the

piston spring plug.

4. Install the inter-spindle.

5. Position the roller guide, roller pin, and roller in

the fuel feed pump housing. Install the retaining

ring.

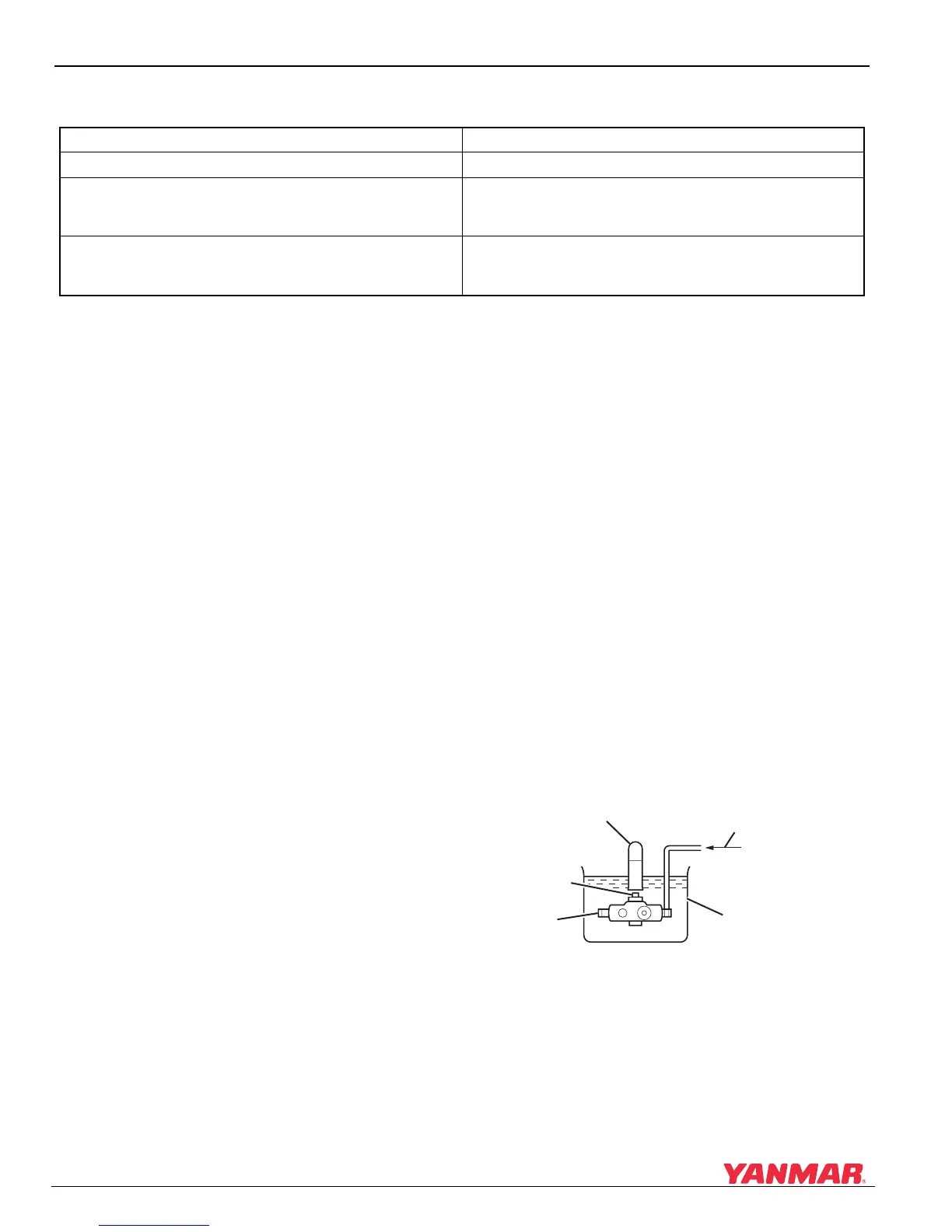

6. When the pump has been reassembled,

perform the air-tightness test. Apply 0.3 MPa

(3 kg / cm

2

) (43 psi) of air pressure

(Figure 6-37, (2)) to the discharge outlet of the

pump and check for air leaks from the O-ring. If

air is leaking, replace the O-ring.

Figure 6-38

Figure 6-38

1 – Measuring Cylinder

2 – Air Pressure

3 – Container Filled with Light Oil

4 – Blocked (Plugged)

5 – Tappet

Item Standard

Maximum Suction Head of Fuel Feed Pump 1.0 m (3.2 ft)

Maximum Discharge Volume of Fuel Feed Pump

11.4 L / min. (3.001 gal.)

at camshaft speed 1500 rpm,

engine speed 3000 rpm

Maximum Discharge Pressure of Fuel Feed Pump

230-370 kPa (2.3-3.8 kgf / cm

2

) (33.3-53.6 psi)

at camshaft speed 1500 rpm,

engine speed 3000 rpm

(1)

(5)

(4)

(2)

(3)

0005701

Loading...

Loading...