ENGINE

Inspecting the Cylinder Block and Components

12/05

6LY3 Service Manual

5-41

© 2007 Yanmar Marine International

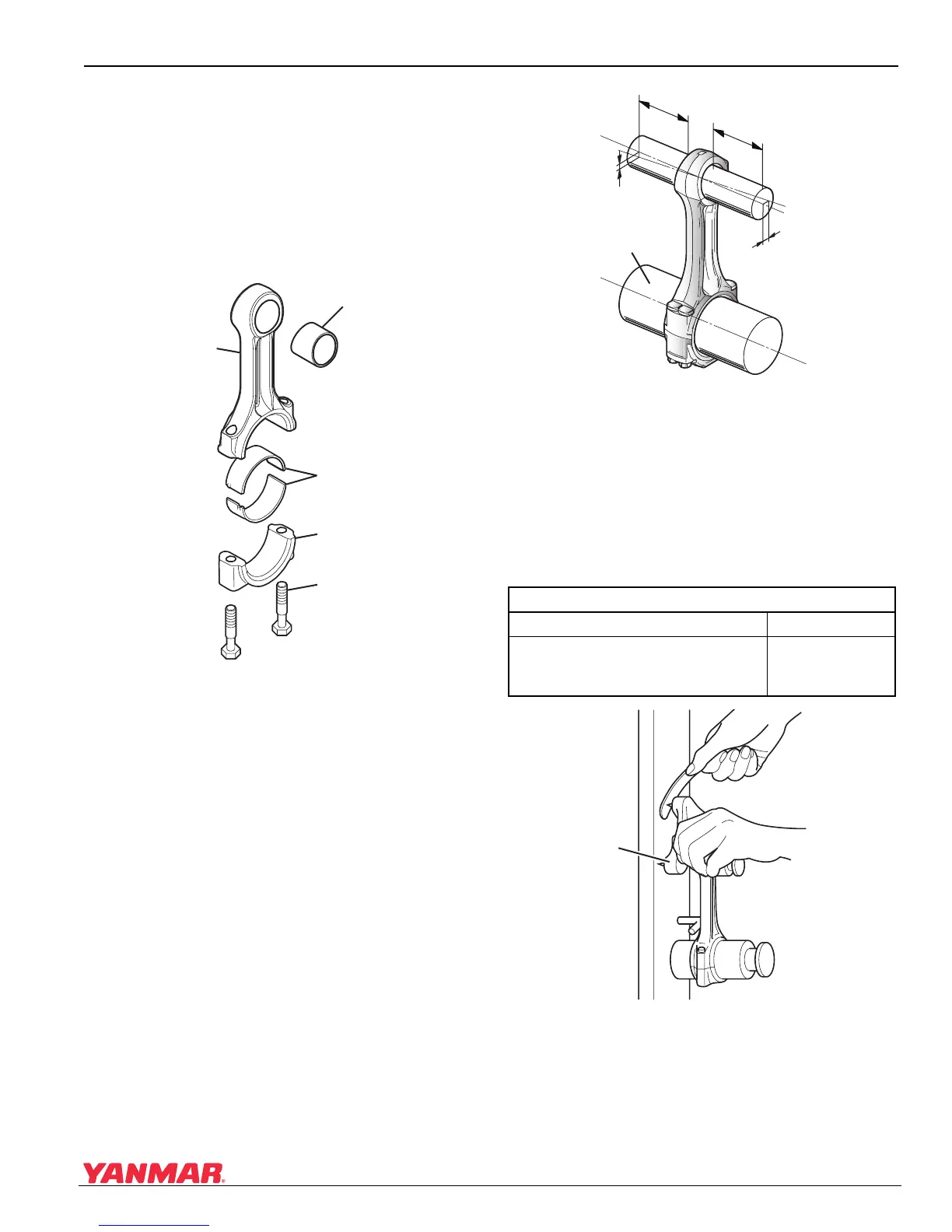

Inspecting the Connecting Rods

The connecting rod (Figure 5-48, (1)) is made of

high-strength forged carbon steel. The large

crankshaft bearing is equipped with a bearing cap

and a 2-piece aluminum bearing insert assembly.

The piston pin bearing (Figure 5-48, (2)) is a

non-serviceable copper alloy bushing that is

factory-installed.

Figure 5-48

Figure 5-48

1 – Connecting Rod

2 – Piston Pin Bearing

3 – Crank Pin Bearing Inserts

4 – Connecting Rod Cap

5 – Connecting Rod Cap Bolts

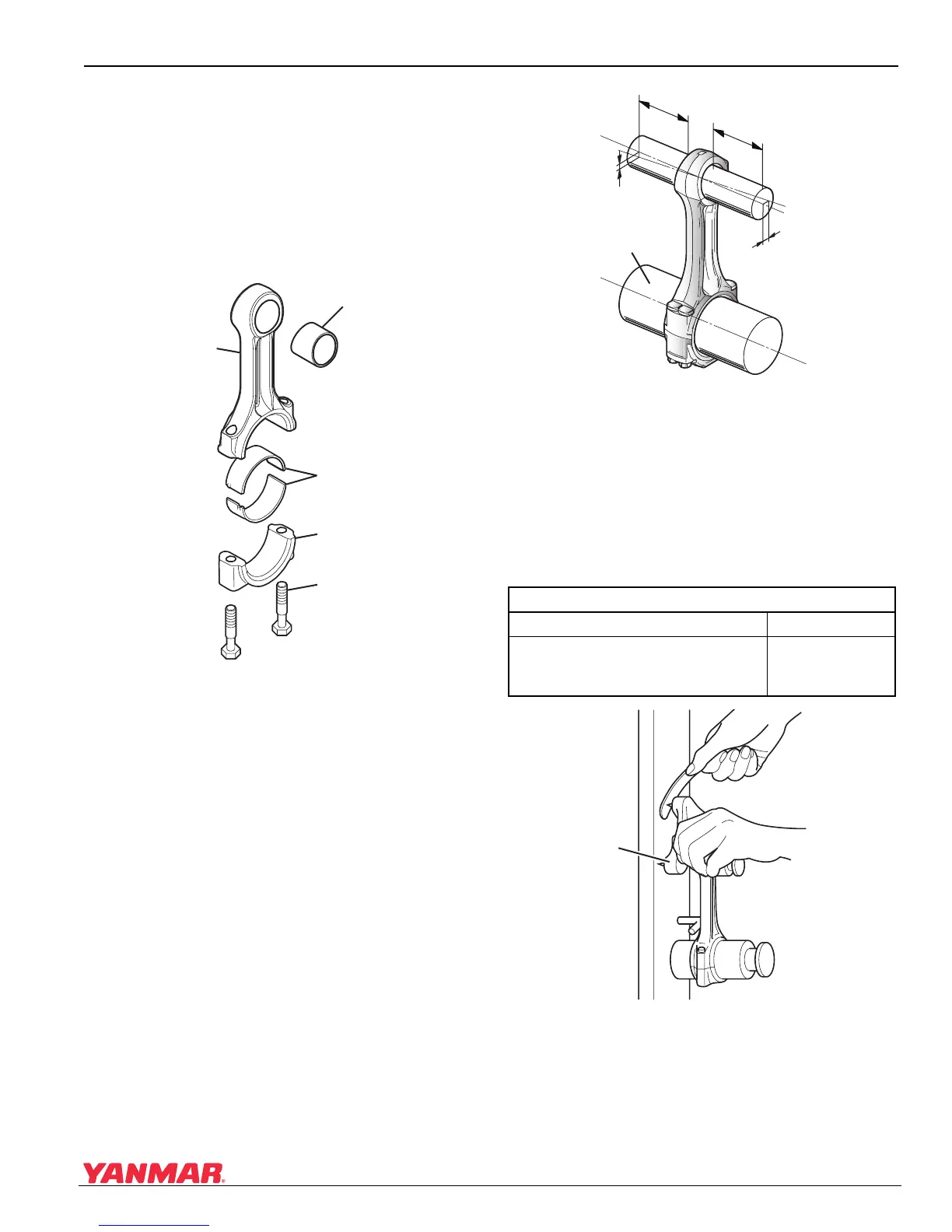

Inspecting the Connecting Rod Bearing

Alignment

Ensure that the connecting rod is not twisted.

• Insert the appropriate mandrel

(Figure 5-49, (3)) into both ends of the

connecting rod.

Figure 5-4 9

Figure 5-49

1 – Parallel Measurement

2 – Twist Measurement

3–Mandrel

• Measure alignment.

• Replace connecting rod if it exceeds the stated

limits.

Figure 5-5 0

Figure 5-50

1 – Connecting Rod Tool

2 – Twist Measurement Using a Rod Alignment

Tool

0005632

(2)

(3)

(5)

(4)

(1)

Connecting Rod Twist

Standard Limit

Less than 0.05 mm

(0.0019 in.)

(at 100 mm (3.936 in.))

0.07 mm

(0.0027 in.)

0005633

(1)

(2)

(3)

100mm

100mm

0005634

(1)

(2)

Loading...

Loading...