FUEL SYSTEM

Fuel Injection Pump / Governor / Timer

6-24 6LY3 Service Manual

© 2007 Yanmar Marine International

Troubleshooting the Fuel Injection

System

Complete repair means not only replacing defective

parts, but also finding and eliminating the cause of

the trouble. The cause of the trouble may not

necessarily be in the pump itself, but may be in the

engine or the fuel system. If the pump is removed

prematurely, the true cause of the trouble may

never be known. Before removing the pump from

the engine, go through the basic inspection items

listed here.

Basic Checkpoints

• Check for breaks or oil leaks throughout the fuel

system, from the fuel tank to the nozzle.

• Check the nozzle spray pattern.

• Check the fuel delivery system operation. Loosen

the fuel pipe connection at the injection pump

inlet and test the fuel feed pump.

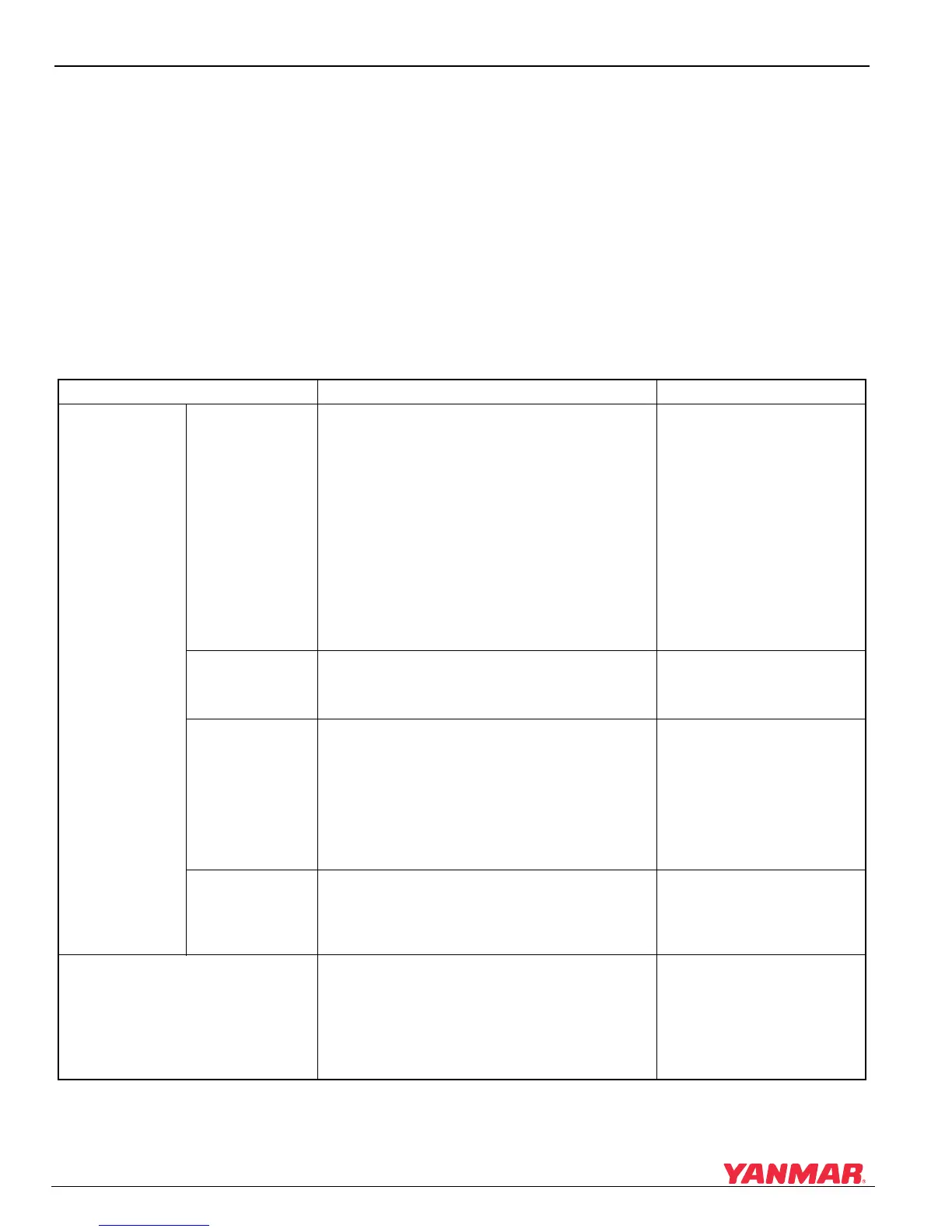

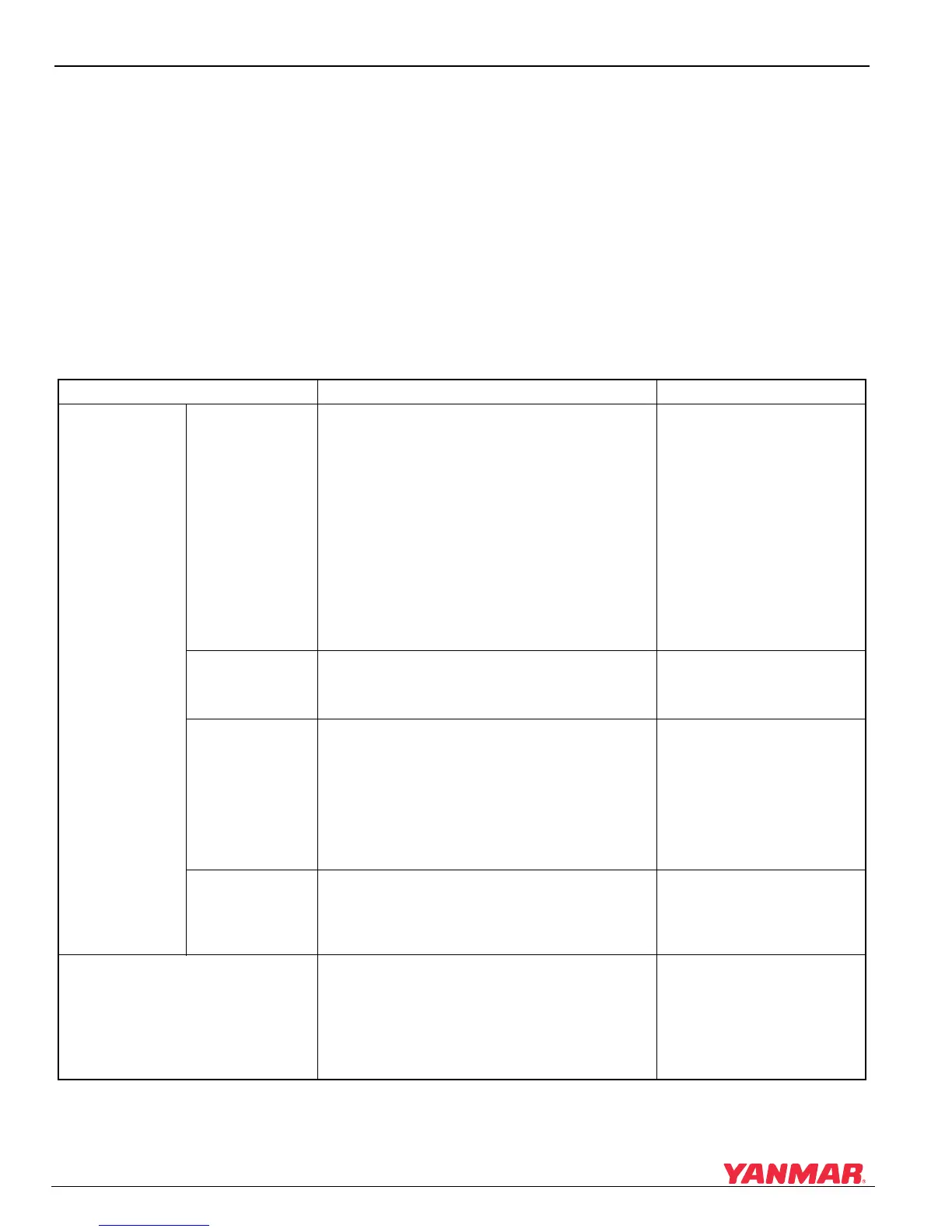

Major Faults and Troubleshooting

Fault Cause Remedy

Engine won’t start. Fuel not delivered

to injection pump.

1. No fuel in the fuel tank.

2. Fuel tank cock is closed.

3. Fuel pipe system is clogged.

4. Fuel filter element is clogged.

5. Air is drawn into the fuel due to defective

connection in the piping from the fuel tank to

the fuel pump.

6. Defective valve contact of the feed pump.

7. Piston spring of the feed pump is broken.

8. Inter-spindle or tappets of the feed pump are

stuck.

1. Fill Tank.

2. Open.

3. Clean and clear.

4. Disassemble and clean,

or replace element.

5. Repair.

6. Repair or replace.

7. Replace.

8. Repair or replace.

No fuel delivered

to injection pump.

1. Plunger is worn out or stuck.

2. Delivery valve is stuck.

3. Control rack will not move.

1. Repair or replace.

2. Repair or replace.

3. Repair or replace.

Nozzle doesn’t

work.

1. Nozzle valve doesn’t open or close normally.

2. Nozzle seat is defective.

3. Injection nozzle starting pressure is too low.

4. Nozzle spring is broken.

5. Fuel filter is clogged.

6. Excessive oil leaks from the nozzle sliding area.

1. Repair or replace.

2. Repair or replace.

3. Adjust.

4. Replace.

5. Repair or replace.

6. Replace the nozzle

assembly.

Injection timing is

defective.

1. Camshaft is excessively worn.

2. Roller guide was incorrectly adjusted or is

excessively worn.

3. Plunger is excessively worn.

1. Replace camshaft.

2. Adjust or replace.

3. Replace plunger assembly.

Engine starts but immediately stops. 1. Fuel pipe is clogged.

2. Fuel filter is clogged.

3. Air is entering fuel lines.

4. Insufficient fuel delivery from the feed pump.

1. Clean.

2. Disassemble and clean, or

replace the element.

3. Replace the packing repair

pipe.

4. Repair or replace.

Loading...

Loading...