1-3

166006-1CD

166006-1CD

1 Introduction

1.2 System Overview

RM2-755/1255SL

Positioner

A tooling plate multiple angle control feature allows the programmer to

define the angle of the tooling presented to the operator (with a resolution

of infinite degrees). This improves load station ergonomics and part

tacking (see 1-2).

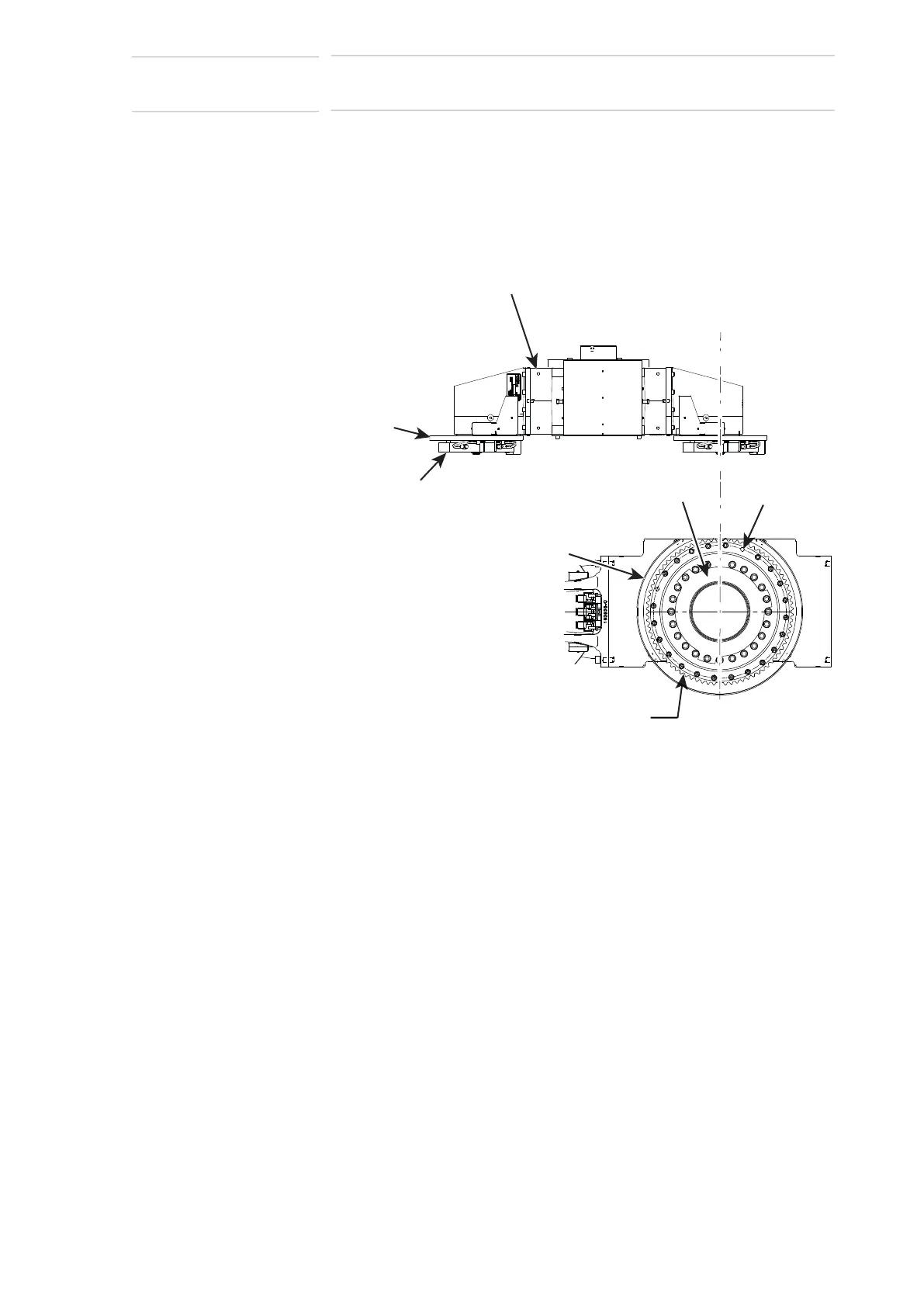

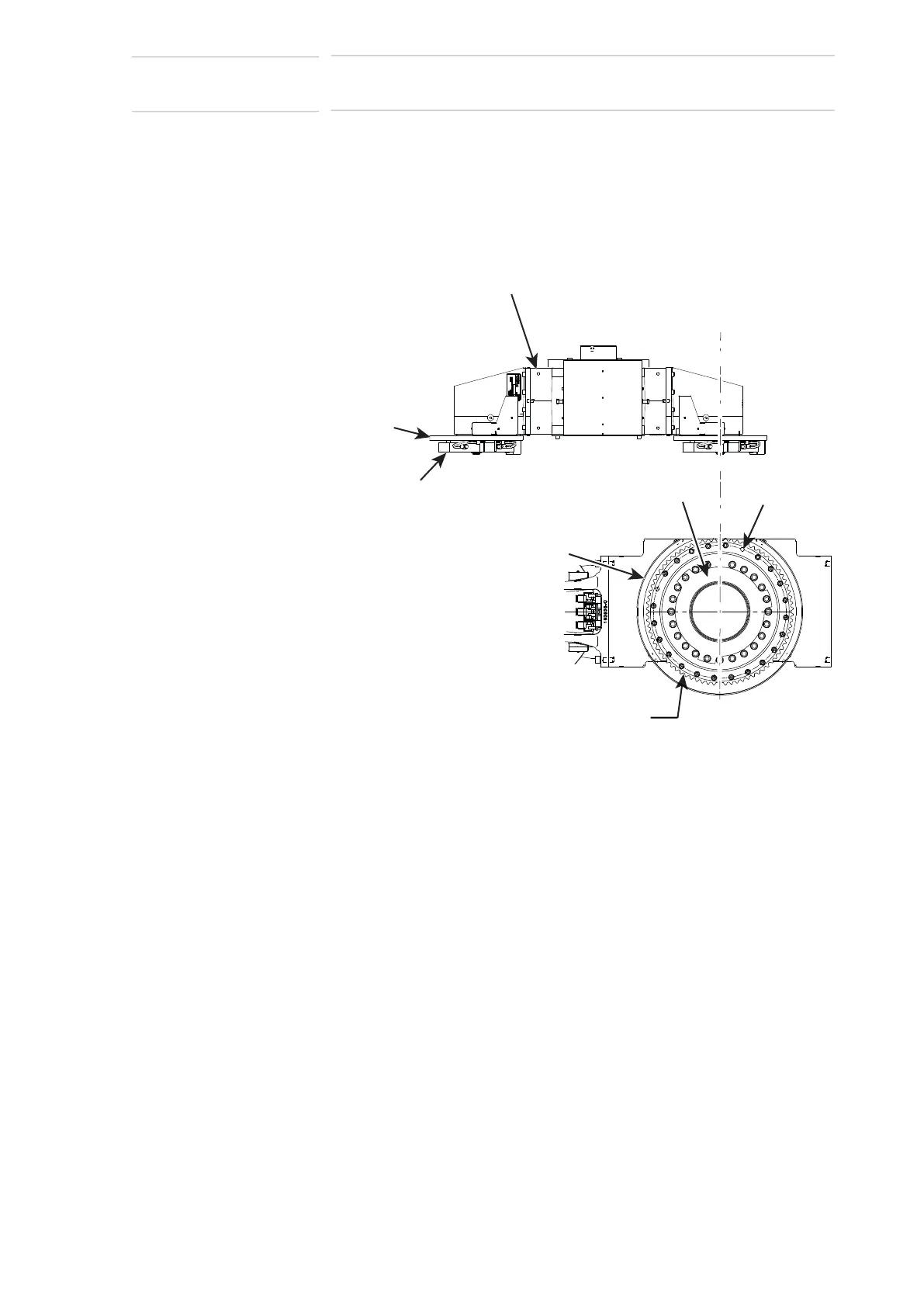

Fig. 1-2: Tooling (Orbital) Axis “S” — Tooling Plate Multiple Angle Control

Components

All Positioner tooling plates are fitted with the MotoMount™ flexible tool

mounting system as the tooling interface (see 1-1 and 1-2).

Each AC servomotor incorporates a small Lithium-Ion “keep alive” battery

pack that maintains servo positioning data in memory, should the main

cables between the Positioner and Controller be disconnected. This

battery pack is a part of each cable assembly (internal to the Positioner)

that connects each AC servomotor to its associated multi-pin plug on the

Positioner base. These battery packs have a very long life. However, if

they drop below a certain charge level, a “low battery” indication appears

on the Programming Pendant LCD display screen.

Refer to Table 4-1 “RM2-755/1255SL Positioner Technical Specifications”

on page 4-1.

TOOLING DRIVE

AXIS, 2 PLCS

SWINGARM ASSY

TOOLING DRIVE

TOOLING

PLATE (REF)

POSITIONING

SLOT (TYP)

A-B POSITION

ACTUATOR

(Non FSU part)

HEADSTOCK

RUBBER WIPER

SENSOR

ACTUATOR

RING

MOTOMOUNT (REF)

Loading...

Loading...