6-24

166006-1CD

166006-1CD

6 Maintenance and Inspection

6.12 Positioner Home Position

RM2-755/1255SL

Positioner

11. Adjust the headstock hardstop adjustment screw compressing conical

spring in the main drive hardstop completely.

12. Back swingarm off of hardstop and tighten jam nut.

13. Rotate Positioner back to B-side position, torque should be 40-45%.

Adjust position with teach pendent (if required) and reset home.

14. Repeat the above step 4 through step 13 to set A-side except set

value to EX040 S1 Position.

15. Jog Positioner to both A & B sides checking the holding torque values.

Readjust position A as required until holding torque stays at 35-45%.

Complete several cycles on both sides for confirmation.

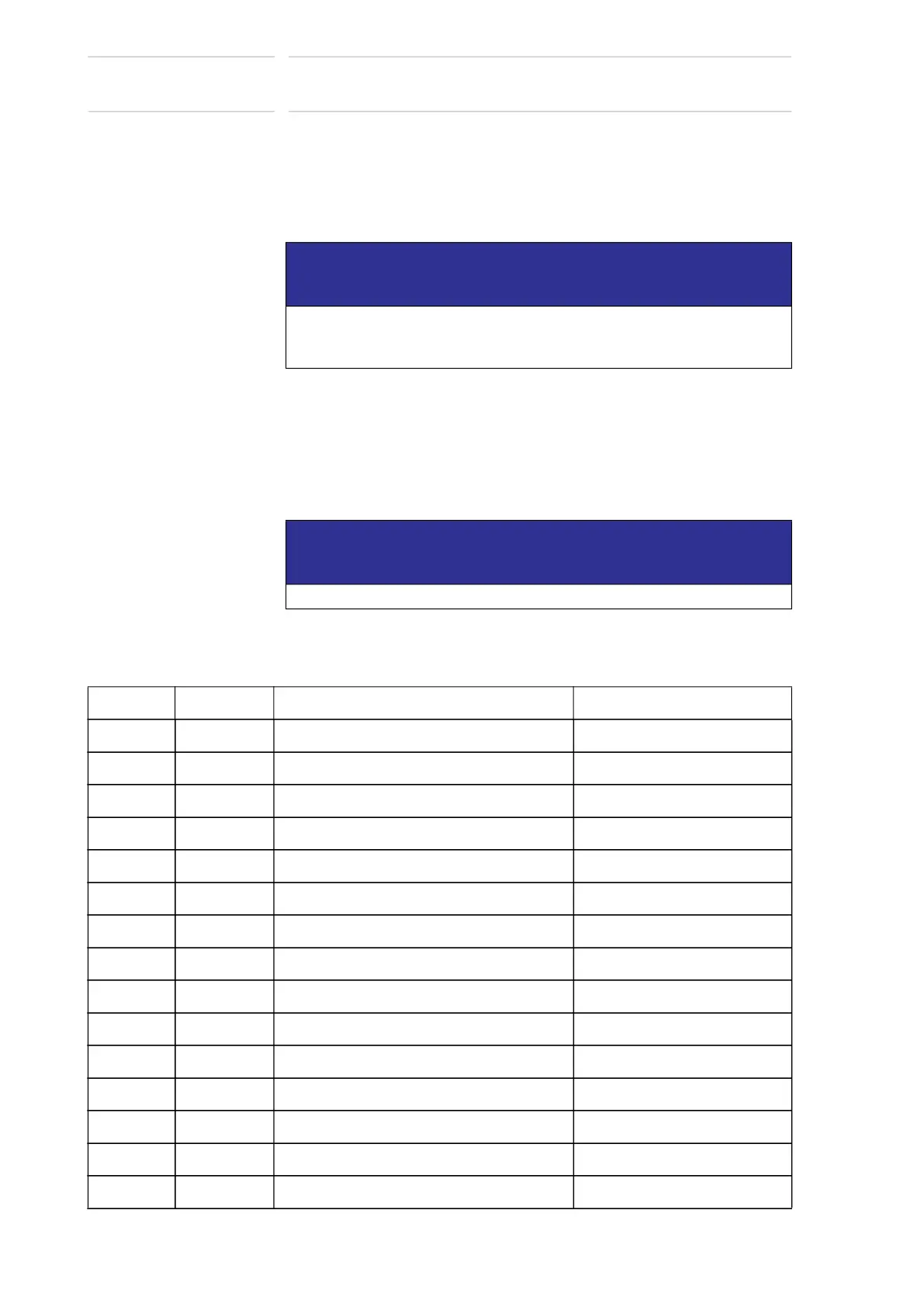

Table 6-4: RM2- Headstocks Position Variables

NOTICE

With the FSU enabled and setting the home position, a message

appears stating to do a flash reset of the FSU in “MAINTENANCE”

mode. A flash reset can be done later in the homing procedures.

NOTICE

When making changes on the “B” side also adjust the “A” side.

Variable Value Descriptions Variable Name

EX040 -180.000°

a)

S1 A-Side At Manipulator S1 A-Side@Robot

EX041 0.000° S2 Tooling At Manipulator S2 @Robot

EX042 -180.000° S3 Tooling At Operator S3 @Operator

EX043 -10.000° S1 Sweep A-Side to Manipulator mid-position S1 A To R1 Mid

EX044 170.000° S2 Sweep to Manipulator mid-position S2 To R1 Mid

EX045 -10.000° S3 Sweep to Operator mid-position S3 To Oper Mid

EX050 0.000° S1 B-Side At Manipulator S1 B-Side@Robot

EX051 180.000° S2 Tooling At Op S2 @Operator

EX052 0.000° S3 Tooling at Manipulator S3 @Robot

EX053 -170.000° S1 Sweep B-Side to Manipulator mid-position S1 B To R1 Mid

EX054 10.000° S2 Tooling Sweep to Operator mid-position S2 To Oper Mid

EX055 -170.000° S3 Tooling Sweep to Manipulator mid-position S3 To R1 Mid

EX060 90.000° S3 Homing Pin to “Level Home” S3 Home Pin to Level Home

EX061 -90.000° S3 “Level Home” to Homing Pin S3 Level Home to Home Pin

EX062 90.000° S2 Homing Pin to “Level Home” S2 Home Pin to Level Home

Loading...

Loading...