4

-32

* 1. The setting is given for 200 V Class Inverters. Double the voltage for 400 V Class Inverters.

* 2. The adjustment procedure is described in the following section.

* 3. This refers to the frequency near the N4-11 set value when accelerating and the N4-28 set value when decelerating.

* 4. This means that the ratios of E1-10 to E1-09 and E1-08 to E1-07 are close to the ratio of E1-13 to E1-06. If the V/f pattern is too close to a straight line,

the power will be reduced. Do not change the setting more than necessary.

* 5. Adjust the following user constants only when problems occur: b1-10, d5-07, N4-11, N4-28, N4-15, N4-17, N4-29, N4-30, and N4-32 to N4-34.

* 6. This setting is for software versions PRG 1040 and later. The factory setting with software versions PRG 1039 and earlier depends on the Inverter

capacity.

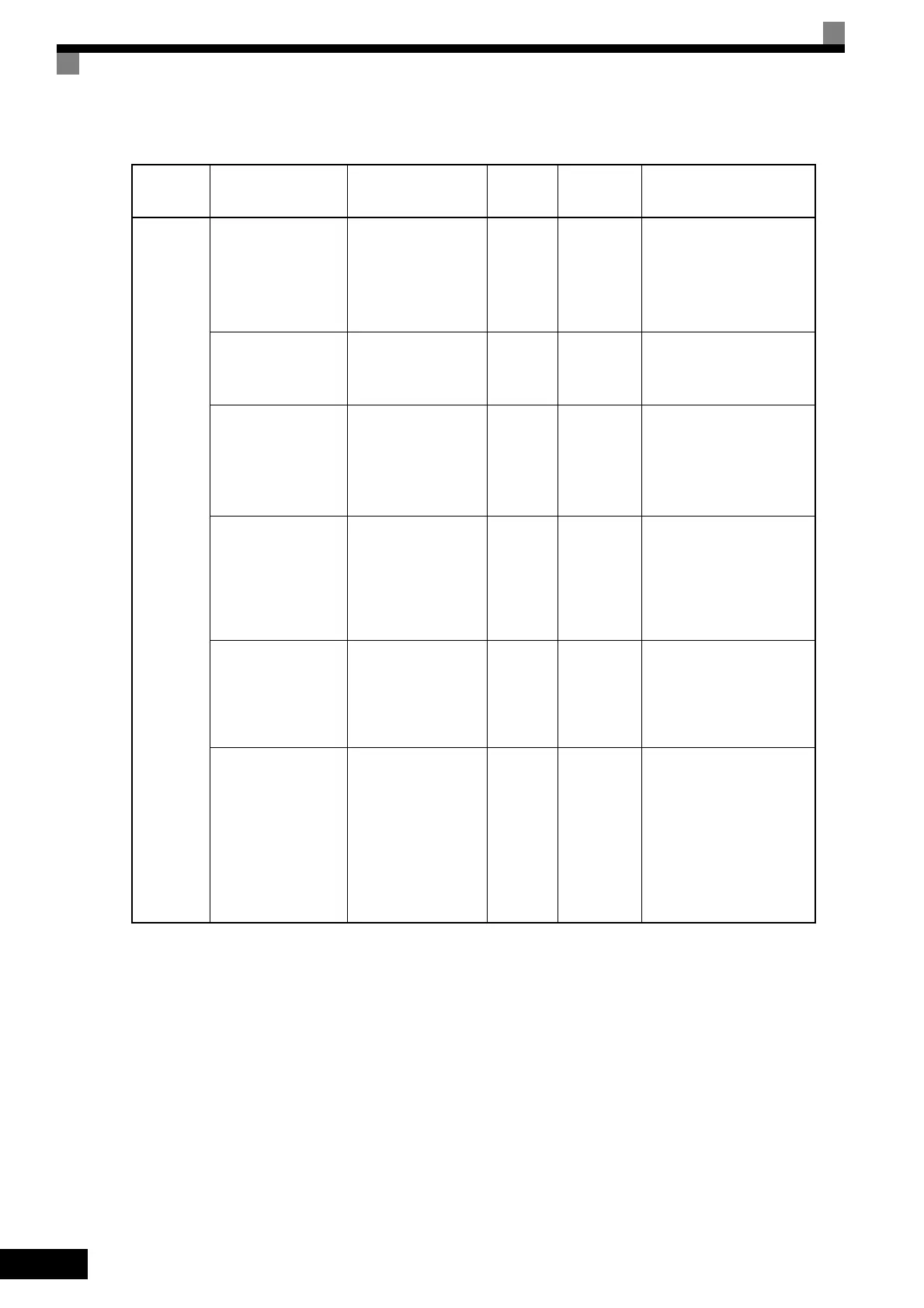

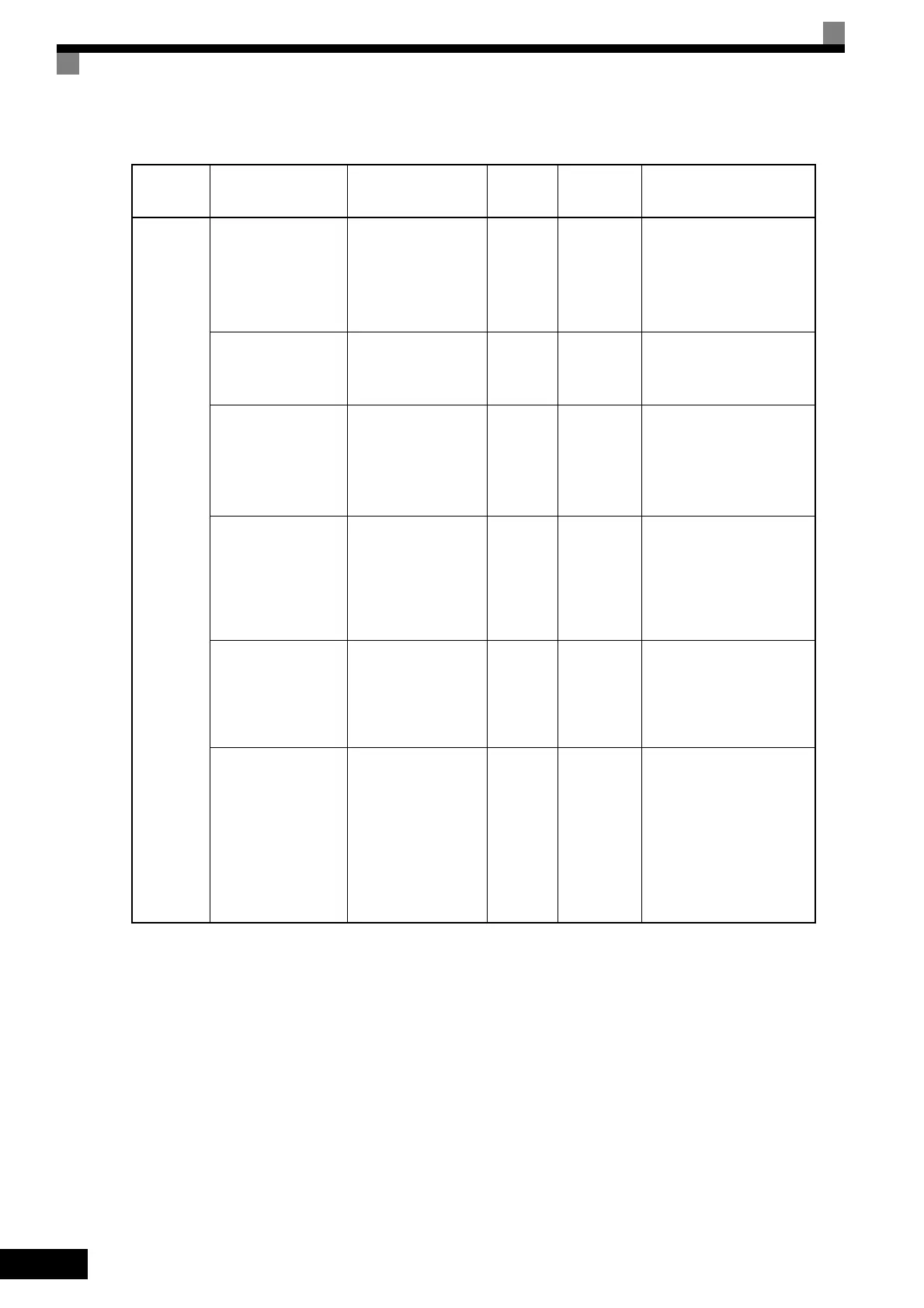

Open-loop

vector 2

control

(A1-02 = 4)

(Continued)

N4-11 (Speed

estimator switching

frequency)

*5

N4-28 (Speed

estimator switching

frequency 2)

*5

Countermeasure when

shock is a problem

near the speed estima-

tor switching fre-

quency

*3

N4-11:

70 Hz

N4-28:

50 Hz

Lower than

default value

Reduce the values of N4-11

and N4-28. (Typically, 5 Hz.)

If the problem is not

improved, use open-loop

vector 1 control (A1-02=2).

N4-15 (Low-speed

regeneration stability

coefficient 1)

*5

Load tolerance (low-

speed regenerative

loads)

0.3

Default

value

Increase the setting if the

power in low-speed regener-

ation is low. (Typically,

increase in intervals of 0.1.)

N4-17 (Torque

adjustment gain)

*5

The torque reference

value (U1-09) in the

low-speed range is

large compared with

the medium- and high-

speed ranges.

0.8 0.8 to 1.0

Increase the setting to 1.0

max. (Typically, increase in

intervals of 0.05.) If the prob-

lem is not improved, bring

the V/f pattern close to a

straight line.

*4

N4-29 (Torque

adjustment gain 2)

*5

Load tolerance (low-

speed electrical loads)

0.10

Default

value

Increase the setting if the

power in low-speed electrical

operation is low. (Typically,

increase in intervals of 0.05.)

Increasing the setting too

much will have the opposite

effect.

N4-30 (Low-speed

regeneration stability

coefficient 2)

*5

Controlling hunting

and vibration (low-

speed regenerative

loads)

1.0 1.0 to 2.5

If vibration occurs during

low-speed regeneration,

increase the setting until the

speed increase becomes a

problem. (Typically, increase

in intervals of 0.2.)

N4-32 to N4-34

(Speed estimator gain

fluctuation frequency

1, 2, and fluctuation

rate)

*5

Controlling hunting

and vibration (6 to 10

Hz)

N4-32:

5 Hz

N4-33:

20 Hz

N4-34:

100%

N4-32:

Around 5 Hz

N4-33:

20 Hz or less

N4-34: 50%

to 100%

First accelerate the motor

gradually and set N4-32 to

the lowest speed at which

vibration occurs. Set N4-33

to the highest speed at which

vibration occurs. And then

reduce the setting of N4-34

until the vibration stops.

(Typically, change in inter-

vals of 5%.)

Table 4.3 Adjusted User Constants (Continued)

Control

Method

Name (Constant

Number)

Performance

Factory

Setting

Recom-

mended

Setting

Adjustment Method

TOE-S616-60.1.book 32 ページ 2017年8月4日 金曜日 午後3時41分

Loading...

Loading...