10

-40

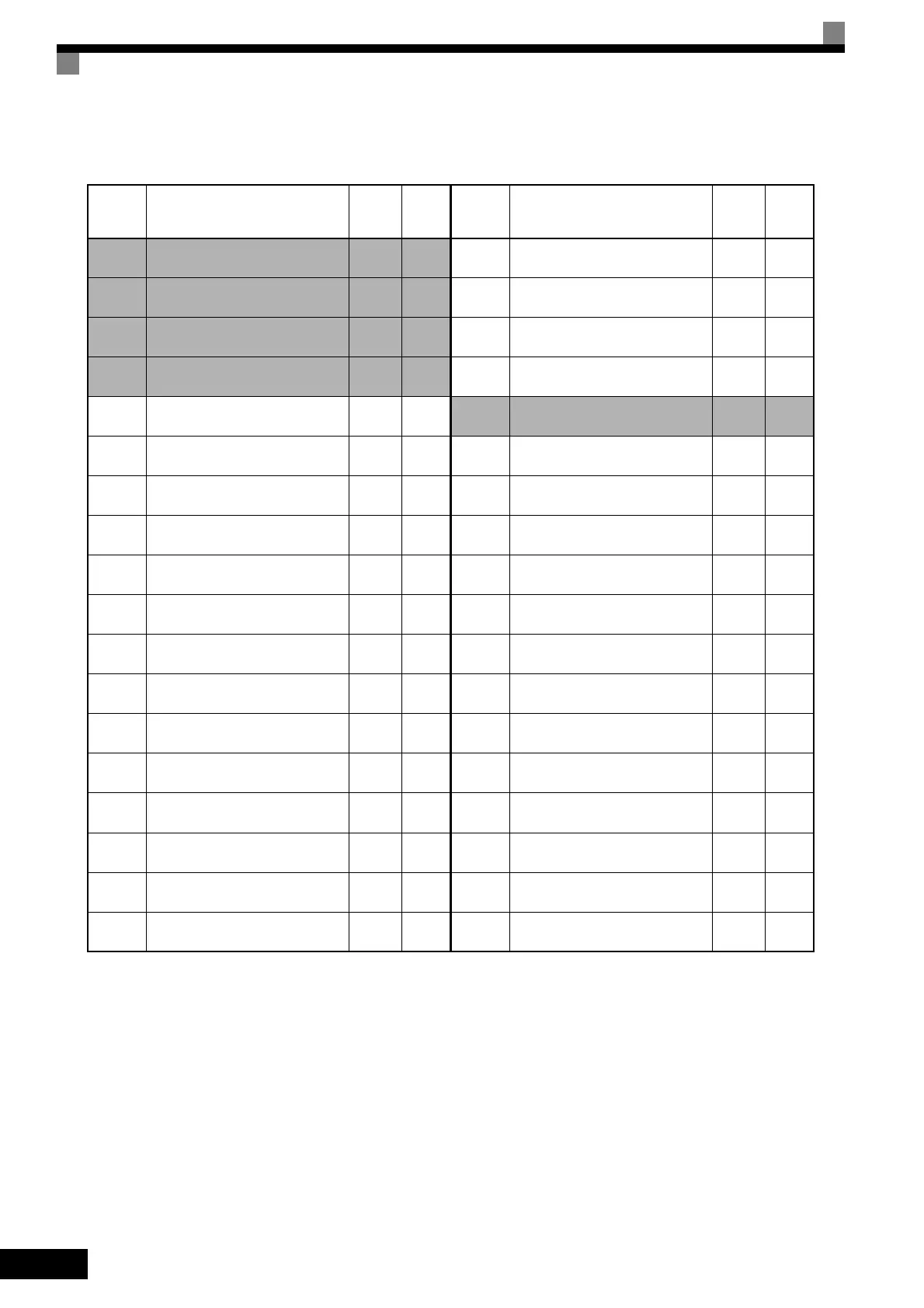

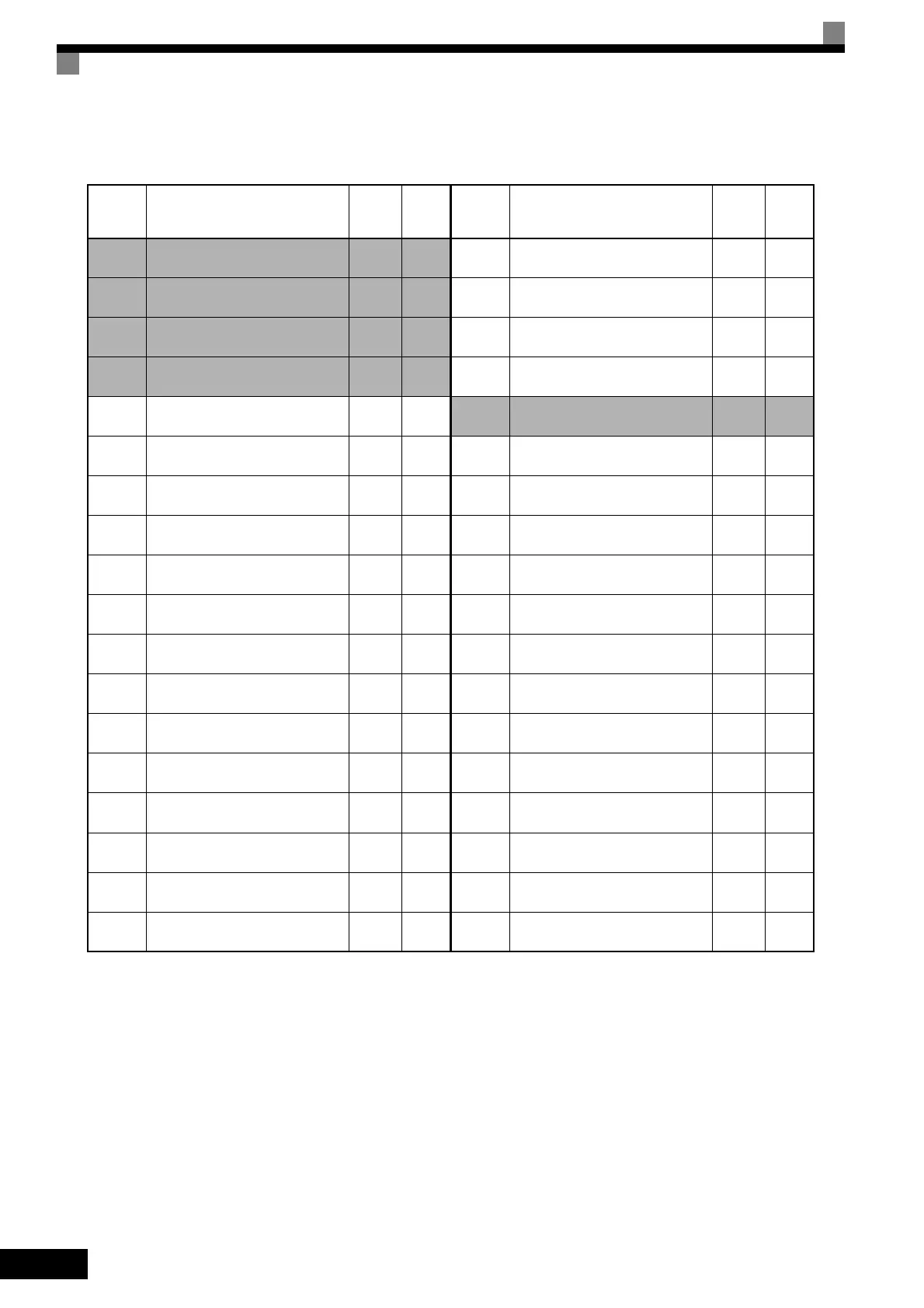

Table 10.9 User Constants (Continued)

* 1. Not initialized. (Japanese standard specifications: A1-00 = 1, A1-02 = 2)

* 2. The factory setting will change when A1-02 (Control Method) is changed. The factory settings of the open-loop vector 1 control are given.

* 3. The factory setting is 1.0 when using flux vector control.

* 4. The factory setting is 2.00 s when Inverter capacity is 55 kW min.

The factory setting will change when the control method is changed. The open-loop vector 1 factory setting is given.

* 5. By setting E2-11 (Motor rated output) the appropriate value will be set.

* 6. The factory settings depend on the Inverter capacity. The values for a 200 V Class Inverter of 0.4 kW are given.

* 7. When the control method is changed, the factory settings will change. The flux vector factory settings are given.

* 8. This constant can be monitored or set only when F is set for C6-02.

* 9. These are values for a 200 V Class Inverter. Values for a 400 V Class Inverter are double.

* 10.E1-11 and E1-12 are disregarded when set to 0.0.

* 11.E1-13 is set to the same value as E1-05 by autotuning.

* 12.The same capacity as that of the Inverter will be set if the constants are initialized.

* 13.Applicable for G7-Series Inverters with software versions PRG 1038 and later. Refer to MECHATROLINK COMMUNICATIONS INTERFACE CARD INSTRUC-

TIONS (TOBPC73060008) for details.

* 14.The factory settings in the parentheses are for 3-wire sequence.

N4-30

Low-speed regeneration stability

coefficient 2

1.00

N4-32

Speed estimator gain fluctuation

frequency 1

5.0

N4-33

Speed estimator gain fluctuation

frequency 2

20.0

N4-34

Speed estimator gain fluctuation

rate

200.0

N5-01 Feed forward control selection

0

*7

N5-02 Motor acceleration time

0.178

*6

N5-03 Feed forward proportional gain 1.0

o1-01 Monitor selection 6

o1-02 Monitor selection after power up 1

o1-03

Frequency units of reference set-

ting and monitor

0

o1-04

Setting unit for frequency con-

stants related to V/f characteristics

0

o1-05 LCD brightness adjustment 3

o2-01

LOCAL/REMOTE key enable/dis-

able

1

o2-02

STOP key during control circuit

terminal operation

1

o2-03 User constant initial value 0

o2-04 kVA selection

0

*6

o2-05

Frequency reference setting

method selection

0

o2-06

Operation selection when digital

operator is disconnected

0

No. Name

Fac-

tory

Setting

Set-

ting

o2-07 Cumulative operation time setting 0

o2-08

Cumulative operation time selec-

tion

0

o2-10 Fan operation time setting 0

o2-12

Fault trace/fault history clear func-

tion

0

o2-14

Output power monitor clear selec-

tion

0

o2-18

*18

Capacitor maintenance setting 0

o3-01 Copy function selection 0

o3-02 Read permitted selection 0

T1-00 Motor 1/2 selection 1

T1-01 Autotuning mode selection

0

*2

T1-02 Motor output power

0.40

*6

T1-03 Motor rated voltage

200.0

*9

T1-04 Motor rated current

1.90

*6

T1-05 Motor base frequency 60.0

T1-06 Number of motor poles 4

T1-07 Motor base speed 1750

T1-08

Number of PG pulses when turn-

ing

600

T1-09

*18

Motor no-load current

1.20

*6

No. Name

Fac-

tory

Setting

Set-

ting

TOE-S616-60.1.book 40 ページ 2017年8月4日 金曜日 午後3時41分

Loading...

Loading...