C4-2

IM 34M06H62-02E 2nd Edition : June 2008-00

C4.1 Set Point (SP)

Any one of the pre-defined set points (1.SP to 4.SP) or a remote set point (RSP) can be

selected as the control set point (CSP). The set points (1.SP to 4.SP) can be stored in

EEPROM for data retention purposes at power off.

This feature is useful, say, for switching between set point values when switching

production between different product types.

- Set the Set Point (1.SP to 4.SP) parameters to different set point values.

- For a loop in Single-Loop or Two-input Changeover mode, or the primary loop in

Cascade control mode, set the Remote/Local Selection (RMT/LOC) parameter to 0

(Local).

- For the secondary loop in Cascade Control mode, set the Automatic/Manual/

Cascade Selection (A/M/C) parameter to Automatic.

- To change the set point, select the desired Set Point parameter using the SP

Number Selection (SPNO) parameter.

- To see which SP number is currently selected, read the CSPNO parameter.

Changing the SPNO parameter in local mode operation selects the following parameters

(where n denotes the value of SPNO and is an integer ranging from 1 to 4).

- n.SP Set Point

- n.A1 Alarm 1 Preset Value

- n.A2 Alarm 2 Preset Value

- n.A3 Alarm 3 Preset Value

- n.A4 Alarm 4 Preset Value

TIP

If the Zone PID Selection (ZONE) parameter is set to ‘0: Disabled’, changing the SP Number Selection

(SPNO) also changes the PID constants, including PB, TI and TD. For details on the parameters that are

changed, see Section C6.9, “PID Selection Method”.

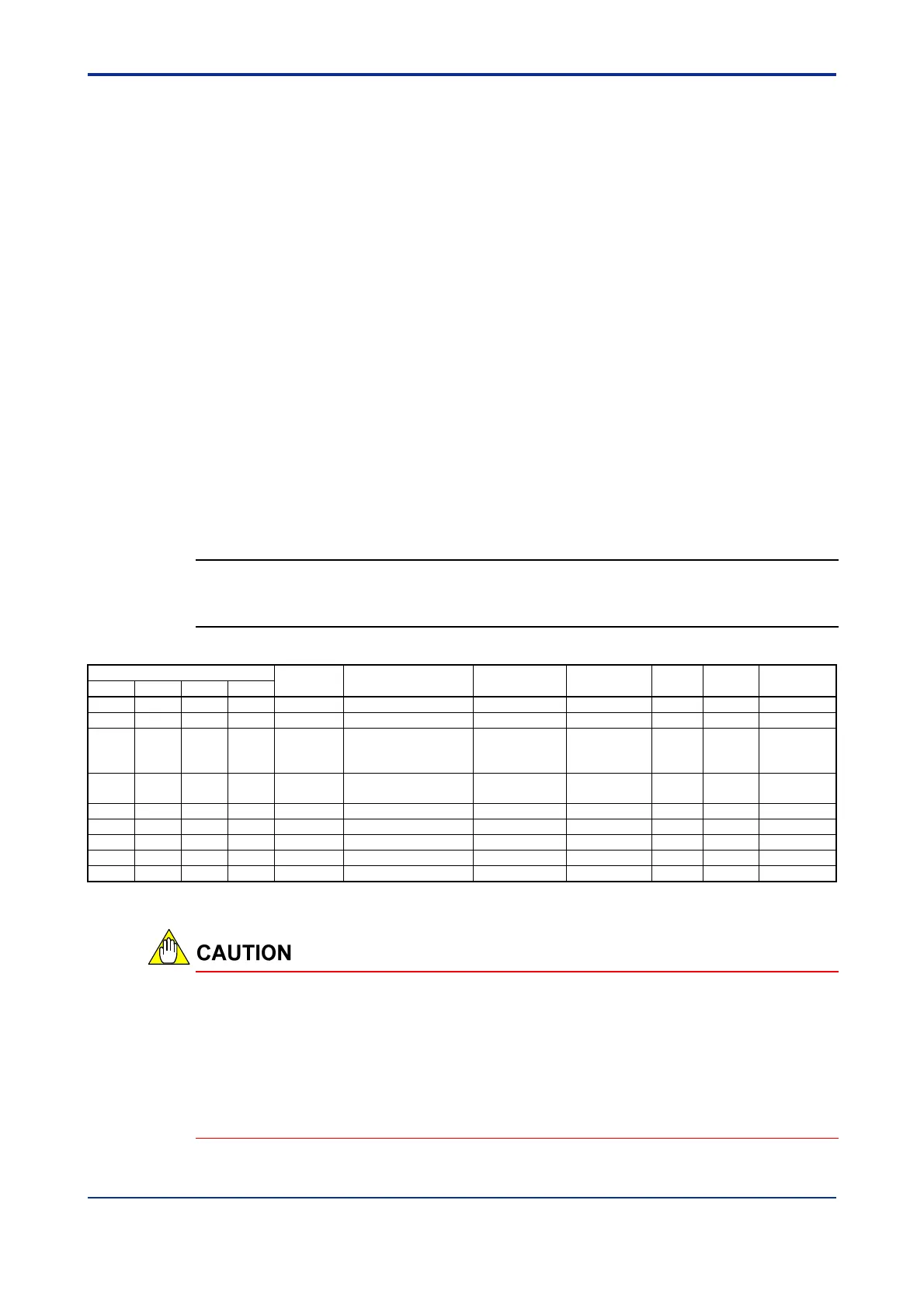

Table C4.1 SP-related Parameters

Data Position Number

Symbol Description

Unit Data Range

Default

Value

Attribute Stored

Loop1 Loop2 Loop3 Loop4

103 303 503 703 CSP Control set point Industrial Unit PRL to PRH — RO —

107 307 507 707 CSPNO Current SP number None 1 to 4 — RO —

122 322 522 722 A/M/C

Automatic/manual/

cascade selection

None

0: Automatic

1: Manual

2: Cascade

*1

0 RW —

124 324 524 724 RMT/LOC Remote/local selection None

0: Local

1: Remote

0 RW —

128 328 528 728 SPNO SP number selection None 1 to 4 1 RW —

201 401 601 801 1.SP Set point Industrial Unit PRL to PRH PRL RW Irregular

221 421 621 821 2.SP Set point Industrial Unit PRL to PRH PRL RW Irregular

241 441 641 841 3.SP Set point Industrial Unit PRL to PRH PRL RW Irregular

261 461 661 861 4.SP Set point Industrial Unit PRL to PRH PRL RW Irregular

*1 The controller mode must be set to Cascade Control before Automatic/Manual/Cascade Selection (A/M/C) can be set

to 2 (Cascade). In cascade control mode, operation proceeds according to the setup for the even-numbered loop

(2 or 4).

- You need to execute a specific procedure every time to update stored set point

values. Otherwise, stored set points will not be updated so the parameters revert to

their last stored values whenever the module is turned off and then on again. For

details, see Section B2.4, "How to Back up SP Values to EEPROM."

- For F3CU04-N, set points (1.SP to 4.SP) are always automatically stored to

EEPROM when updated. Updating set points frequently may damage the EEPROM

stoarge media. Therefore, if the set point is to be changed continually (as a ramp

signal, for example), you should make use of the remote set point (RSP) instead.

Loading...

Loading...