A2-9

IM 34M06H62-02E 3rd Edition : Jul.16

2015-00

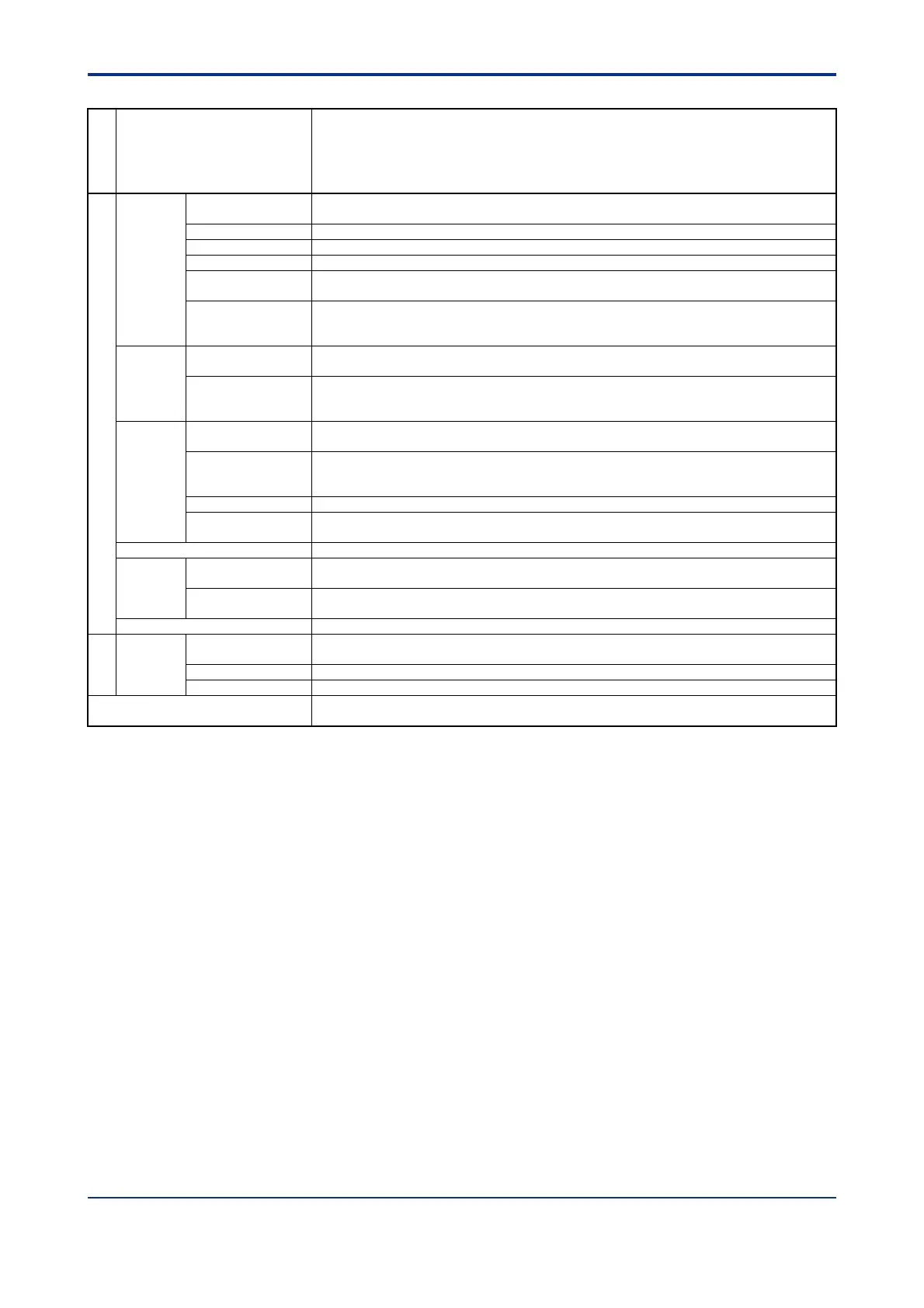

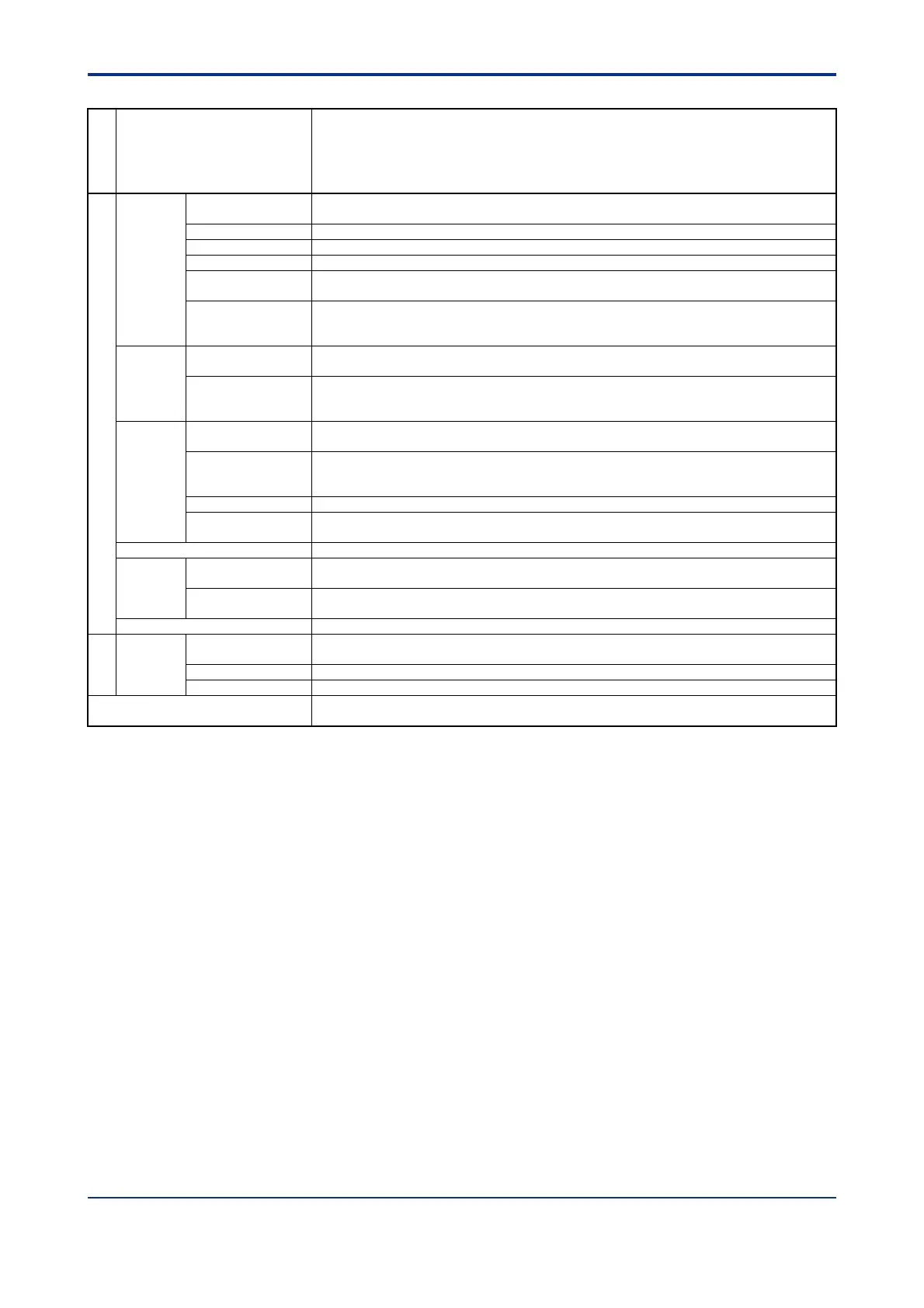

Table A2.7 Function List (2/2)

Category

Functions Description

Control and computation

Set point

Set points

Four set points can be predefined for each loop. A predefined set point can be selected using the

SP number parameter.

Remote set point Can be used to continually change the set point value from the CPU module or by other means.

SP tracking Retains the set point value when switching from remote to local mode.

SP limiter Limits the set point within specified limits in remote or cascade control mode.

SP gradient

setting

Defines acceleration and deceleration independently for varying the control set point at a fixed rate

or to prevent an abrupt change in the control set point.

PV tracking

When a switchover is made from Stop to Run, from Manual to Automatic, or from one SP number to

another, the control set point is first set to the current PV value and then gradually changed to the

required value at the rate defined by the SP gradient parameters.

Auto-

tuning

Dynamic

auto-tuning

Automatically recalculates PID constants to achieve continuous stable control at the beginning of a

control operation or when control becomes unstable.

Auto-tuning

When a start tuning instruction is issued, measures the characteristics of a control object by

switching on and then switching off the output, and automatically determines and sets optimal PID

constants.

Control

and

compu-

tation

Forward/reverse

operation

Defines the direction of output change (increase or decrease) corresponding to a positive deviation.

PID control mode

The combination of the CMD parameter (0: standard PID control mode, 1: fixed-point control mode)

and the remote/local switch determines the PID control method (PV derivative type PID control or

deviation derivative type PID control) with or without bumping.

Super Suppresses overshooting using fuzzy logic.

Anti-reset windup

Prevents excessive integration and hence overshooting by suspending PID computation. The

deviation width for resuming PID computation can be set using a parameter.

PID selection Selects one of the four PID parameter groups belonging to each loop.

PID

selection

method

SP number

selection

Switches between four PID parameter groups according to the value of the SP Number Selection

parameter.

Zone PID selection

Automatically switches between PID parameter groups according to PV value. In addition, allows

switching to a specific PID parameter group when the deviation is large.

Operation control Switches between run/stop, automatic/manual/cascade, remote/local, and other operating modes.

Alarm

Alarm

Alarm setup

Defines four alarms for each loop. Alarms may be defined to trigger with respect to the upper or

lower input limit or differential upper or lower limit.

Waiting Suppresses alarms during the startup period after power on until the operation stabilizes.

Delay timer Reports an alarm only if an alarm condition persists for a minimum duration.

Backup function

(Storing of preset values)

Stores parameters to the EEPROM, which is writable up to 100,000 times.

Loading...

Loading...