JOHNSON CONTROLS

166

FORM 155.32-ICOM1.EN.GB

ISSUE DATE: 10/13/2017

SECTION 8 – TROUBLESHOOTING

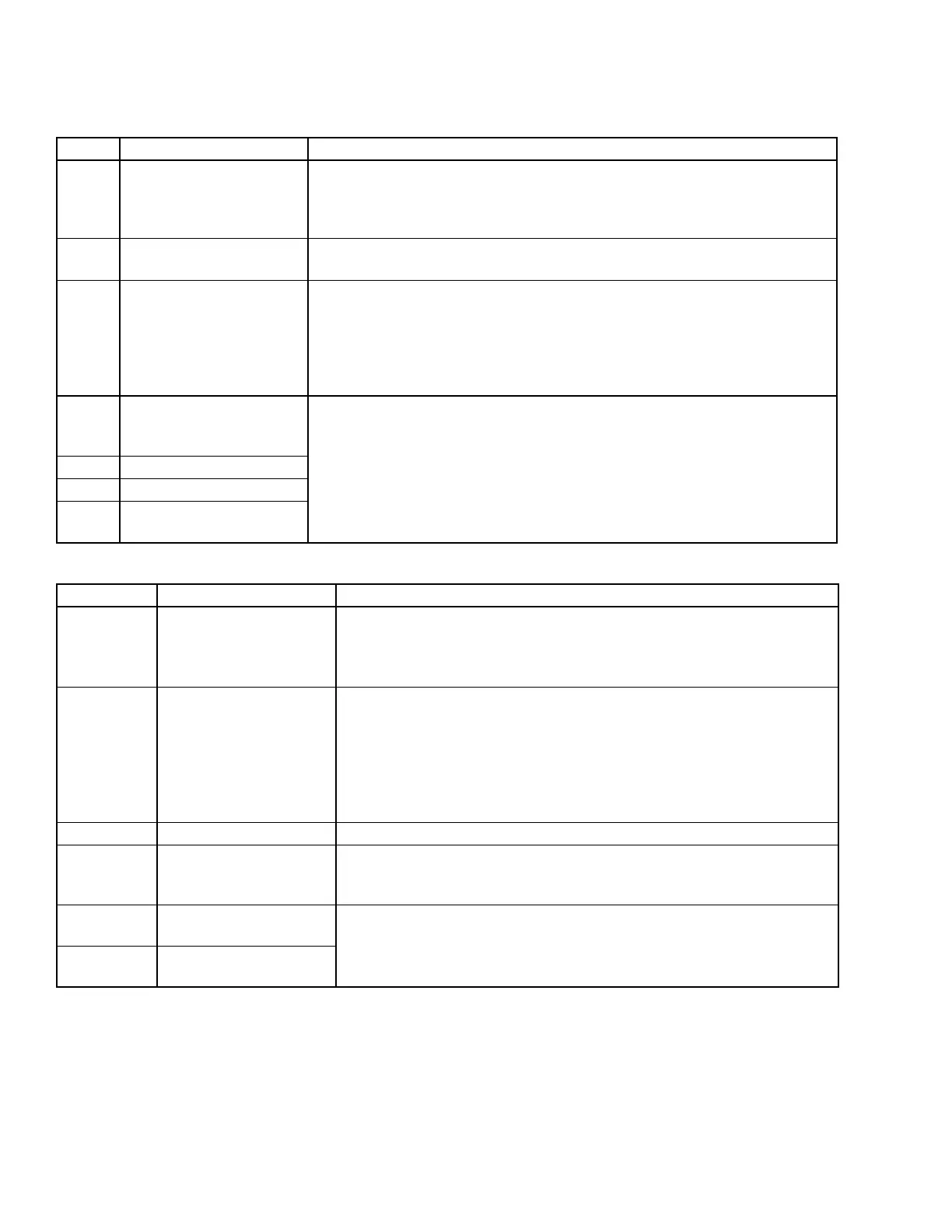

TABLE 42 - TROUBLESHOOTING THE HIGH

TEMPERATURE GENERATOR

ITEM CAUSE COUNTERMEASURE

1

Cooling water is insufcient

or suspended.

• See if the cooling water supply rate conforms to the specication. (Check the ow

meter, discharge pressure of the cooling water pump, current, etc.)

• If the ow rate is insufcient, check the opening ratio of the ow controller valve

and check the strainer for clogging.

2

Cooling water temperature

at inlet is high.

Check the capacity of the cooling tower.

3

Non-condensable gas stays

in the machine.

• Check the capacity of the vacuum pump.

• Check the purge unit.

• Purge air from the chiller-heater (See SECTION 7 – MAINTENANCE).

• If partial load operation continues for a long period, non-condensable gas tends

to stay in the absorber. In this case, purge directly from the absorber. Use the

instructions shown in SECTION 7 – MAINTENANCE).

4

Heat exchange tube is dirty

(chilled/hot water, cooling

water).

Contact your local Johnson Controls Service Ofce.

5 Solution is crystallized.

6 Corrosion inhibitor is worn.

7

Air leaks in absorption

chiller-heater.

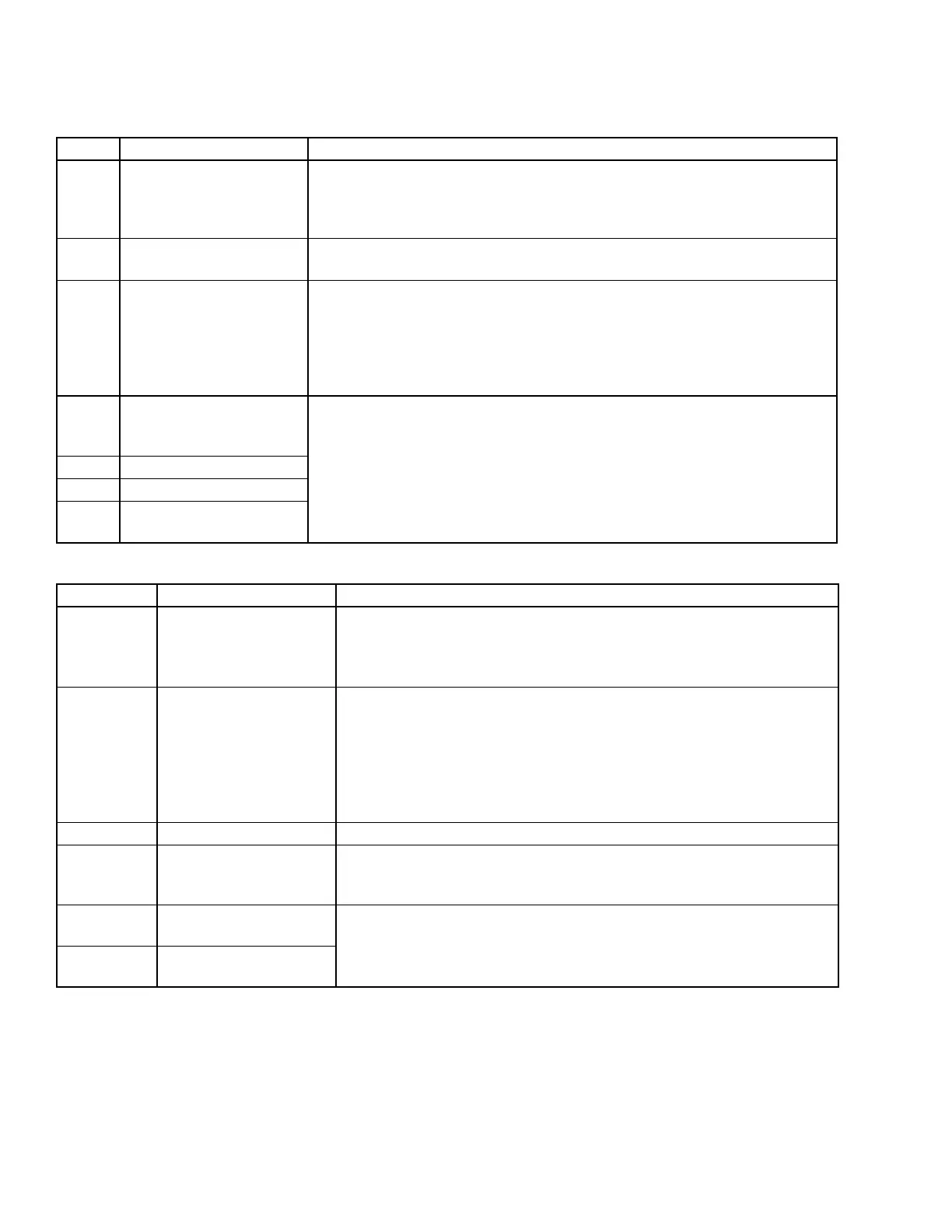

TABLE 43 - REFRIGERANT OVERCOOLING RELAY

ITEM CAUSE COUNTERMEASURE

1

Chilled/hot water ow rate

lowers or changes sharply.

• See if the chilled/hot water ow rate changes sharply (particularly in the case

of variable ow rate specication).

• If it changes sharply, apply a limit of the change rate to the chilled/hot ow

control or take another measure.

2

Cooling water temperature

at inlet changes sharply.

• See if the cooling water temperature at inlet changes sharply (by checking

start and stop of the fan).

• If the chiller-heater refrigerant temperature is low, the chiller-heater stops

immediately but does not perform the diluting operation. If left as it is, the

solution may be crystallized in 4-5 hours. To prevent this, dilute the solution

according to the information shown in Manual Refrigerant Blow Down and

Diluting Method on page 142.

3 Load lowers sharply. See if the load changes sharply.

4

Refrigerant is dirty

(contains solution).

See if the refrigerant rening operation has been performed periodically. For

the refrigerant rening method, see Refrigerant Rening Method on page

142.

5

Heat exchange tube is

dirty (Chilled/hot water).

Contact your local Johnson Controls Service Ofce.

6

Temperature controller or

safety switch is broken.

Loading...

Loading...