ControlMaster CM30, CM50 and CMF310

Universal process controllers,

1

/4,

1

/2 DIN and fieldmount 6 Basic Level

IM/CM/ED–EN Rev. X 29

…Basic

Loop 1 (2) Control

On/Off Hysteresis Sets the hysteresis value in engineering units.

Note. Applicable only if Control Type is On/Off – see page 49.

Mode Tur ns the Autotune functionality on or off. When set to On, an Autotune can be started from

the Operator level menus – see page 23.

Autotune Autotune is a user-activated feature that enables automatic setting of the controller PID

parameters (see page 30) using an

'at setpoint type' algorithm. Autotune changes the

controller output and then monitors the process response to calculate the optimum PID

settings. Autotune uses a relay-type function with hysteresis that initiates a controlled

oscillation in the process. New PID parameters are calculated and stored in the controller

automatically.

Note. To achieve the best results from Autotune, switch the controller to Manual control

mode (see page 6) and adjust the output until the PV is stable (close to the normal setpoint)

before initiating Autotune.

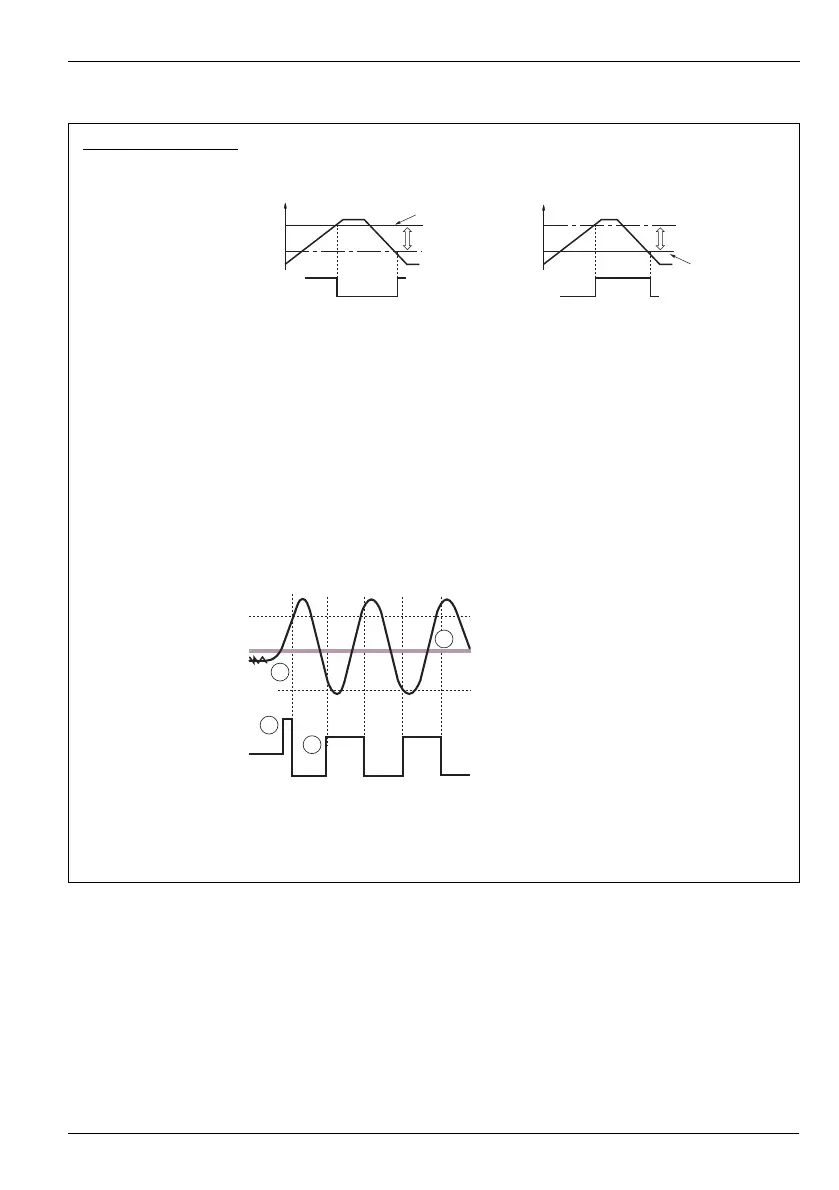

Autotune Operation

The Autotune sequence is shown in the following figure:

PV

PV

ON

OFF

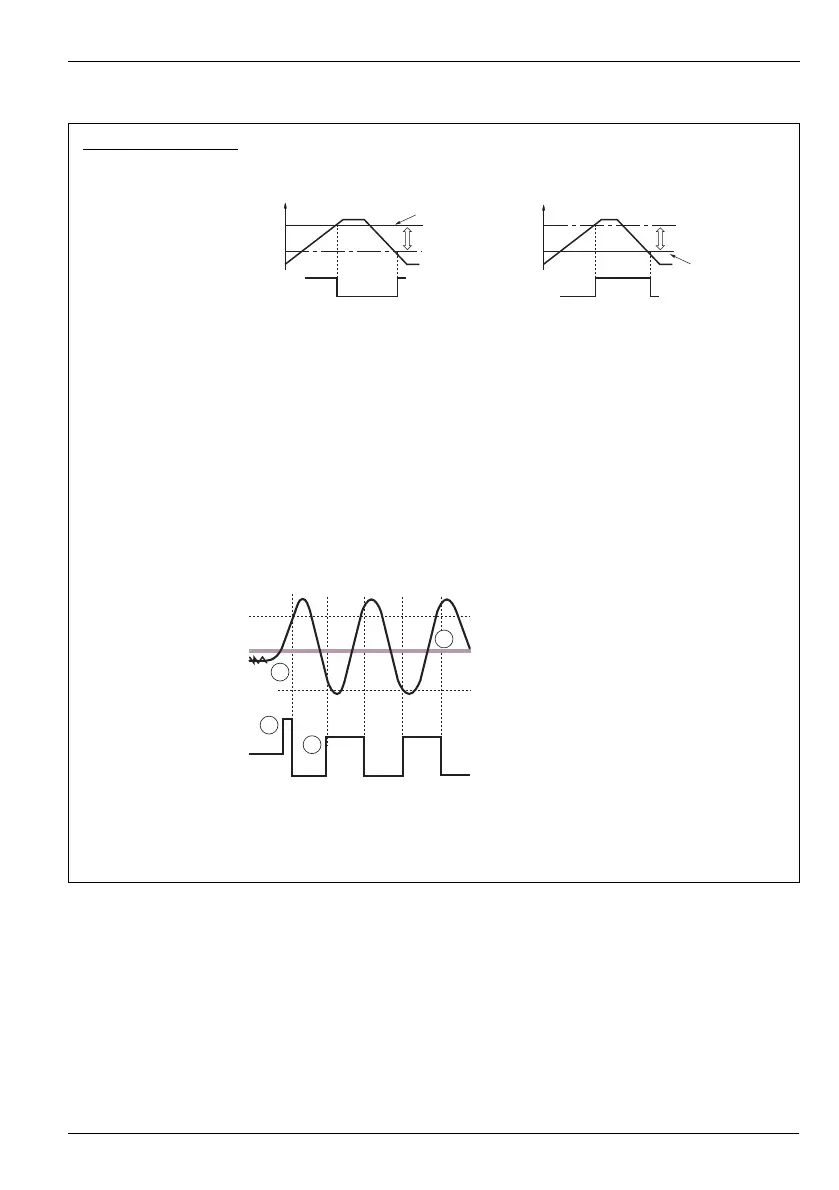

Reverse Acting Control Output

Setpoint

Hysteresis

Value

Hysteresis

Value

Setpoint

Direct Acting Control Output

ON

OFF

SP

PV

1 Set the first step value and dynamics required. For best

results, select the largest initial output step size that can

be tolerated by the process.

2 Autotune is enabled only if the control type is PID.

3 Start Autotune from the Operator menu.

4 Monitors a noise A and calculates a hysteresis

value

?

5 User-defined initial step in the output B.When the

process exceeds the hysteresis value the output is

stepped down.

6 Adjusts output amplitude automatically C so PV

disturbance is kept to minimum required.

7 When consistent oscillation is established D, the

Autotune process stops. Optimum settings are

calculated from the process dynamics monitored.

Loading...

Loading...