76 Troubleshooting and Maintenance Manual

4 General Maintenance

Before Starting

For your safety, read all of the information in this introduction before

performing any maintenance tasks.

Scheduled maintenance

Common maintenance tasks are listed in Table 6. Performing these tasks

when scheduled can reduce operating problems, prolong system life, and

reduce overall operating costs.

Keep a record of system performance (tune reports) and maintenance

operations performed. This makes it easier to identify variations from normal

operation and to take corrective action.

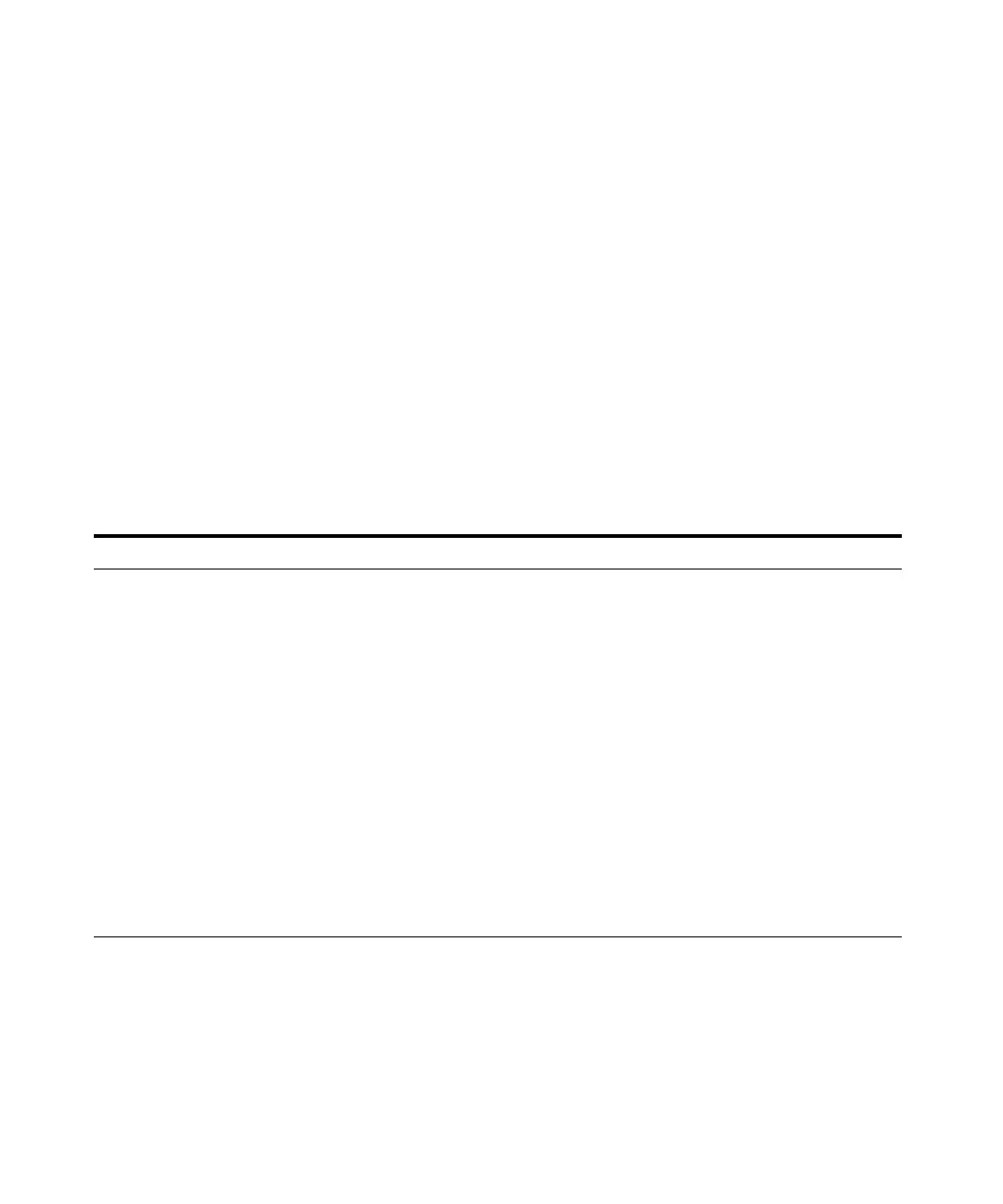

Table 6 Maintenance schedule

Task Every week Every 6 months Every year As needed

Tune the MS X

Check the foreline pump oil level X

Check the calibration vial X

Replace the foreline pump oil

*

X

Check the foreline pump X

Clean the ion source X

Check the carrier gas trap(s) on the GC and MS X

Replace the worn out parts X

Lubricate side plate or vent valve O-rings

†

X

Replace CI Reagent gas supply X

Replace GC gas supplies X

* Every 3 months for CI MSs using ammonia reagent gas.

† Vacuum seals other than the side plate O-ring and vent valve O-ring do not need to be lubricated.

Lubricating other seals can interfere with their correct function.

Loading...

Loading...