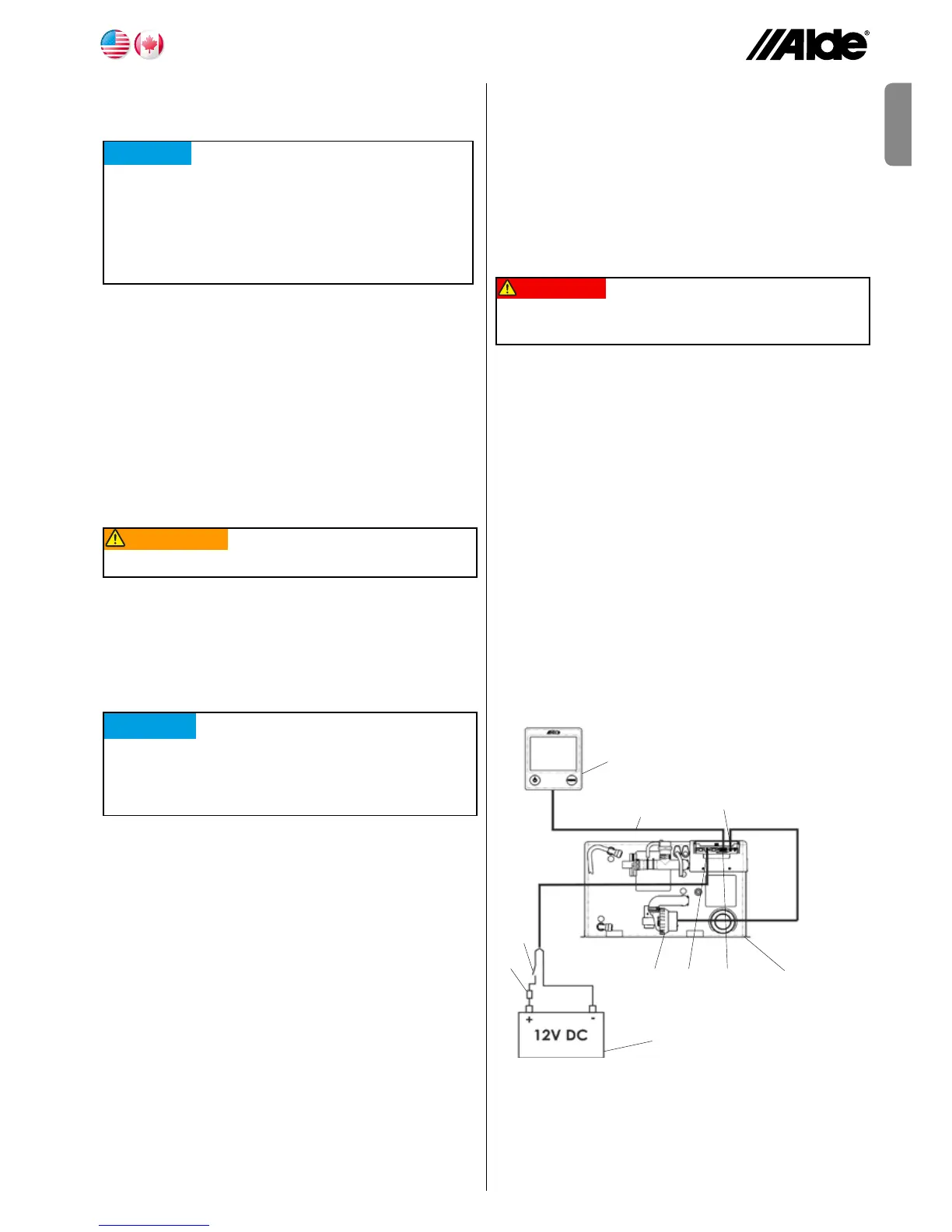

THE ELECTRICAL CONNECTION

12 VOLT DC(gE)Connecttheextensioncable(Figure

E34)betweenthecontrolpanelandtheLPgasboiler.

Supplyof12voltstotheboilermustbedirectfromthe

batteryviathevehicle’smainbreaker(FigureE35)or

aseparatebreaker(theboilerconsumersabout70mA

whenitisinstand-byorisswitchedoff).Afuse(Figure

E36)of5Amustbemountedclosetothebattery.The

plusandminuscablebetweenthebatteryandtheboiler

shallhaveanareaof16AWG1,3mm2upto65feet(20

meters)length(32feet/10mforpositivecableand32

feet/10mforminuscable).Withlongercablelengths,

theareamustbeincreasedto14AWG2,1mm2.Ifa

transformerisusedinsteadofbattery,itmustbeofgood

quality,givingproperdirectcurrentandnotpulsingdirect

current.

120 VOLT ~ Connecttheboiler(electricalheatingele-

ment)securelyto120V~andsecurewitha16Abreaker

for1,9kWelectricalheatingelements.Theboilermustbe

protectivelyearthed.Theinstallationmustbecarriedout

byaqualiedpersonaccordingtocurrentnationalregula-

tions.OnlygenuineconnectioncablefromAldemaybe

used.

FILLING THE HEATING SYSTEM

Theheatingsystemshallbelledwithaliquidmixture

consistingofwaterand“GRAS”(generallyrecognizedas

safe)non-toxicpropyleneglycol.Preferablyuseready-

mixedglycolofhighquality(withinhibitor)intendedfor

aluminumheatingsystems.Whenusingconcentrated

glycol,themixtureshallbe60%distilledwaterand40%

glycol.Iftheheatinginstallationissubjectedtolowertem-

peraturesthan-15°F(-25°C),theglycolcontentshould

beincreased;however,notmorethan50%.Thetank

forhandlingtheliquidmustbeabsolutelyclean,andthe

pipesintheheatingsystemmustbefreefromcontamina-

tion.Thisistopreventthegrowthofbacteriaandtomini-

mizetheriskofcorrosionintheheatingsystem.Filling

theheatingsystemiscarriedoutintheexpansiontank,

eithermanuallyorusingAlde’sllingpump(1900811),

whichbothllsandbleedsthesystem.Whenllingmanu-

ally,theliquidmustbepouredinslowlyuntilthelevelis

about1/2inch(1cm)abovetheMINlineonthetank.

Bleedtheheatingsystem.Pourinsomemoreifthelevel

34.Cable.

35. Switch.

36.Mainfuse5A.

37.12VConnection.

38.2-poleconnection

plinthonboiler.

120 V ~ must be well separated from 12 V.

hasgonedownfrombleeding.Withanewlylledheat-

ingsystem,bleedatregularintervalsduringtherstdays

thattheheatingisrunning.Forothercareoftheheating

system,seetheUserInstructions.

INSPECTING THE SYSTEM

The LPG system

• AlwayschecktheLPGasinstallationforleaksafter

installationorservice.

• Ifthereisleakage,localizetheleakwithleaksprayor

soapywater.

• Checkthatthereductionvalveisattherightpressure.

THE HEATING SYSTEM

• Theheatingsystemshallbecheckedforleakswhen

theentiresystemisvisible,i.e.,beforethextures

havebeenmounted.Checkscanbemadeintwo

ways.Eitherleakagecontrolwith0.75–1.0barover

15min.-pressurereductionmax.0.05bar,orbyll-

ingthesystemwithliquidandcheckingvisually.

Noleakageofliquidisacceptable.

• Checkthatallhoseclipsaremountedandcorrectly

located.

MISCELLANEOUS

• Checkthatthedrainhosesontheexpansiontank

andthedraincockforhotwaterarenotblocked.

• Checkthatueandhosesarecorrectlyinposition,

andthathoseclipsaremountedandfastened.

• Checkthattheboiler’sservicereporthasthemanu-

facturingnumberandinstallationdateenteredinit.

NOTICE

If there is no glycol liquid in the heating system,

wait before connecting 12 V to the boiler This is so

that the boiler shall not be started by mistake with-

out glycol. The cable must not be extended. Only

use genuine cables from Alde, which are available

in various lengths.

39. ControlPanel3010614.

40.Circulationpump12V.

42.Boiler.

43. 10-poleconnection

plinth.

44. Battery12V.

Figure E

34

36

37

38

39

43

42

44

35

40

Loading...

Loading...