APOC0274 Ed.3a

Page 32 of 35

+44 (0)1235 861 483 | aleretoxicology.co.uk

Alere™ DDS

®

2 Mobile Analyser User Guide | 13. Technical Support, Codes and Troubleshooting

13.1 Technical support

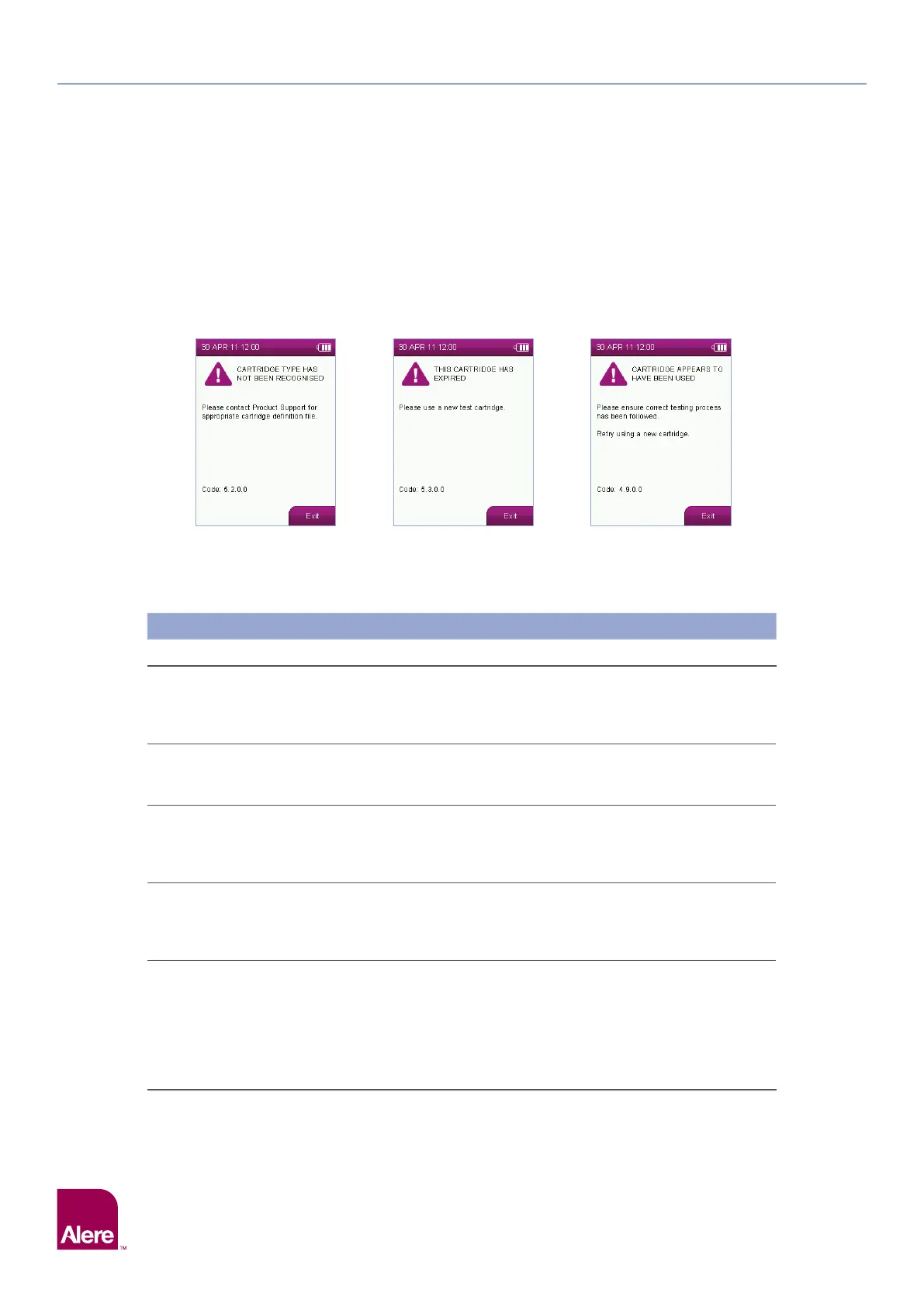

In the event of an incomplete test or Alere DDS2 Mobile Analyser issue, in most cases on screen feedback

will be provided to the user to assist with diagnosis and resolution of the issue. In some cases, the analyser

will report specific codes – please refer to the list of codes on the following pages for interpretation. If the

issue cannot be resolved using this guide, please contact Product Support.

Examples of screens:

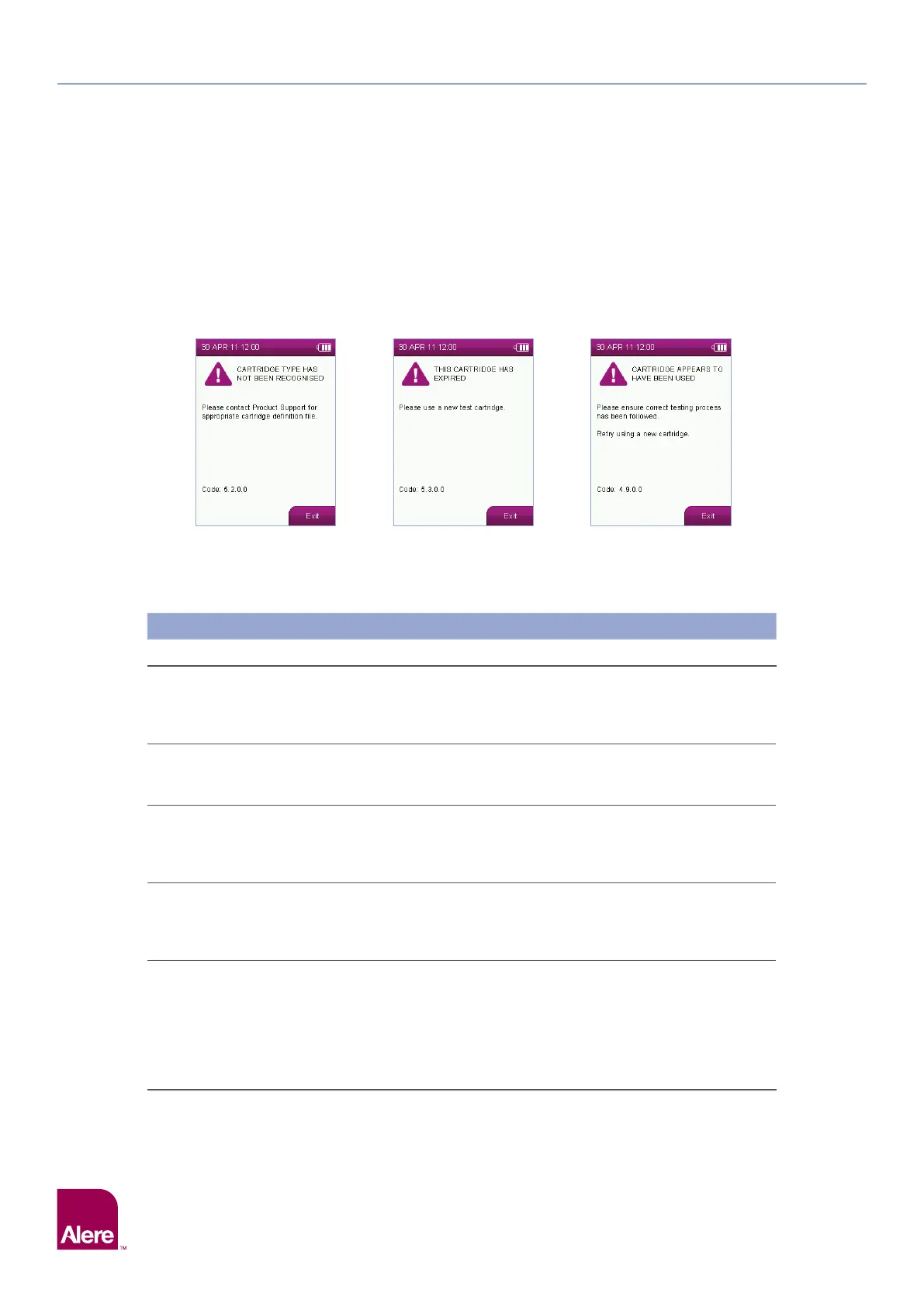

13.2 Codes and troubleshooting

Please note, the codes listed below are examples. When displayed by the Alere DDS2 Mobile Analyser, the

characters denoted by ‘X’ will be numbers. The first and second numbers are used to denote the type of code.

Codes and Troubleshooting

Code Description Possible Causes Solutions

1.1.X.X

to

1.5.X.X

Cartridge

analysis

incomplete.

The test cartridge was not detected

correctly. Can be due to dirty optics,

a damaged test cartridge or a

hardware fault.

Initiate a QC test, if the QC test fails contact

Product Support. If the QC tests pass

complete the test.

1.6.X.X

Insufficient

sample.

The reference band has not been

detected; the sample has not run on

the test cartridge.

Ensure that the test process has been

correctly followed.

1.7.X.X

Insufficient

sample.

The sample has not run sufficiently

on the test cartridge. Can be due

to insufficient sample collection,

incorrect test process.

Ensure that the test process has been

correctly followed.

1.8.X.X

to

1.10.X.X

Cartridge

analysis

incomplete.

The test cartridge was not detected

correctly. Can be due to dirty optics,

a damaged test cartridge or a

hardware fault.

Initiate a QC test, if the QC test fails contact

Product Support. If the QC tests pass

complete the test.

2.1.X.X

to

2.6.X.X

Cannot read

barcode.

During the barcode analysis the

analyser has detected a fault this

could be due to the test cartridge/

barcode being damaged, dirty optics

or a hardware fault.

Initiate a QC test. If the QC test passes, verify

that the inserted test cartridge is not used

and its barcode is not damaged. If the test

cartridge or its barcode is damaged, dispose

of the test cartridge and start a new test

with a new test cartridge. If the QC test fails,

contact Product Support.

13 Technical Support, Codes and Troubleshooting

Loading...

Loading...