306 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

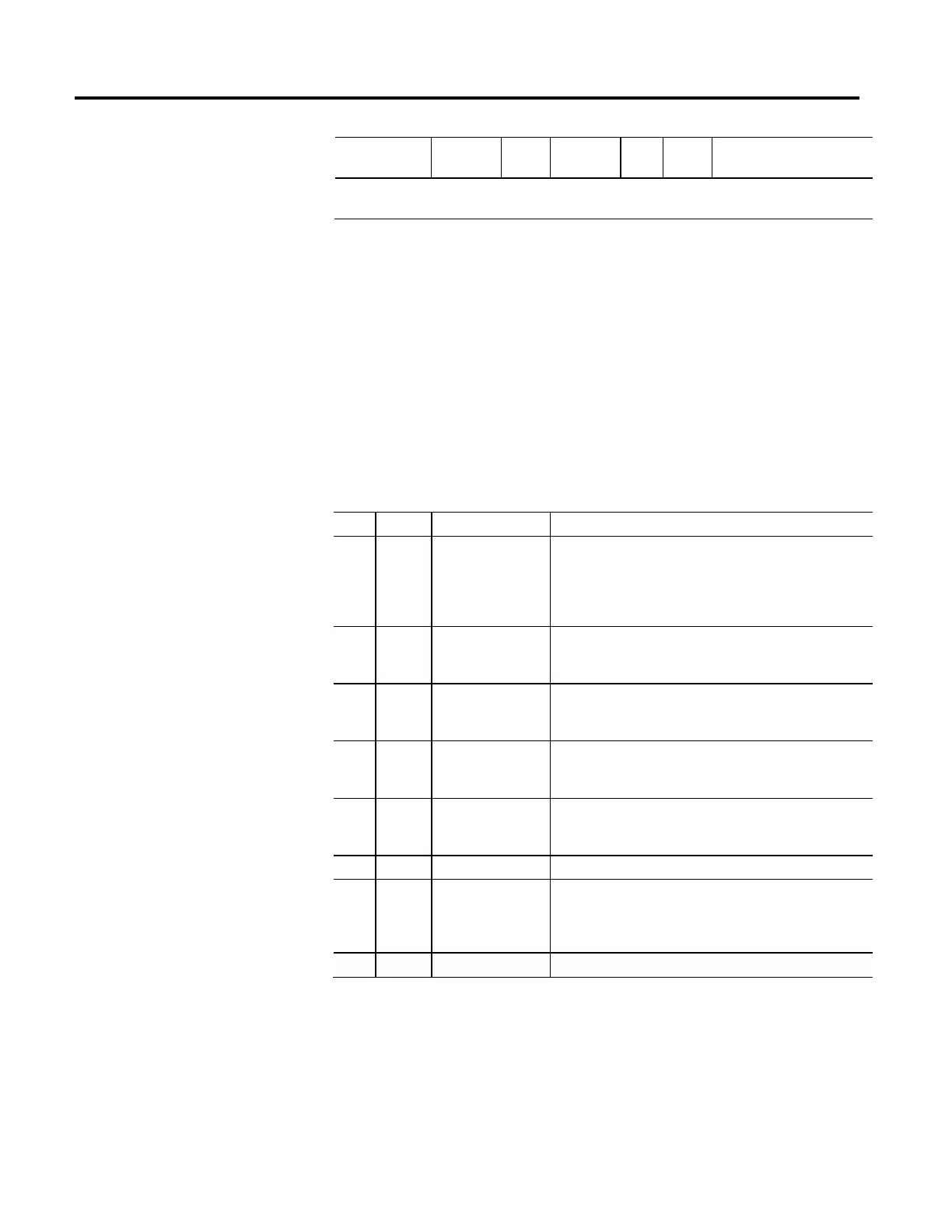

Usage Access Data

Type

Default Min Max Semantics of Values

* Ind

icates the attribute cannot be set while the drive power structure is enabled (Power Structure Enable bit in CIP Axis Status

is true).

The Feedback Mode attribute determines how the various available feedback

channels are used to implement the selected Control Mode. This attribute is

transferred to the device as part of the Cyclic data block. Currently only bits 0-3

are used to enumerate the Feedback Mode configuration.

Feedback Mode enumerations provide support for multi-feedback device control

functionality for the various active device Control Modes, for example, where the

device is actively controlling the motor based on feedback. In these active device

Control Modes it is assumed that logical channel, Feedback 1, is attached directly

to the motor while Feedback 2 is attached to the load side of the mechanical

transmission. Commutation signals for a PM motor are always derived from the

Feedback 1, except in the case of an active redundant feedback source.

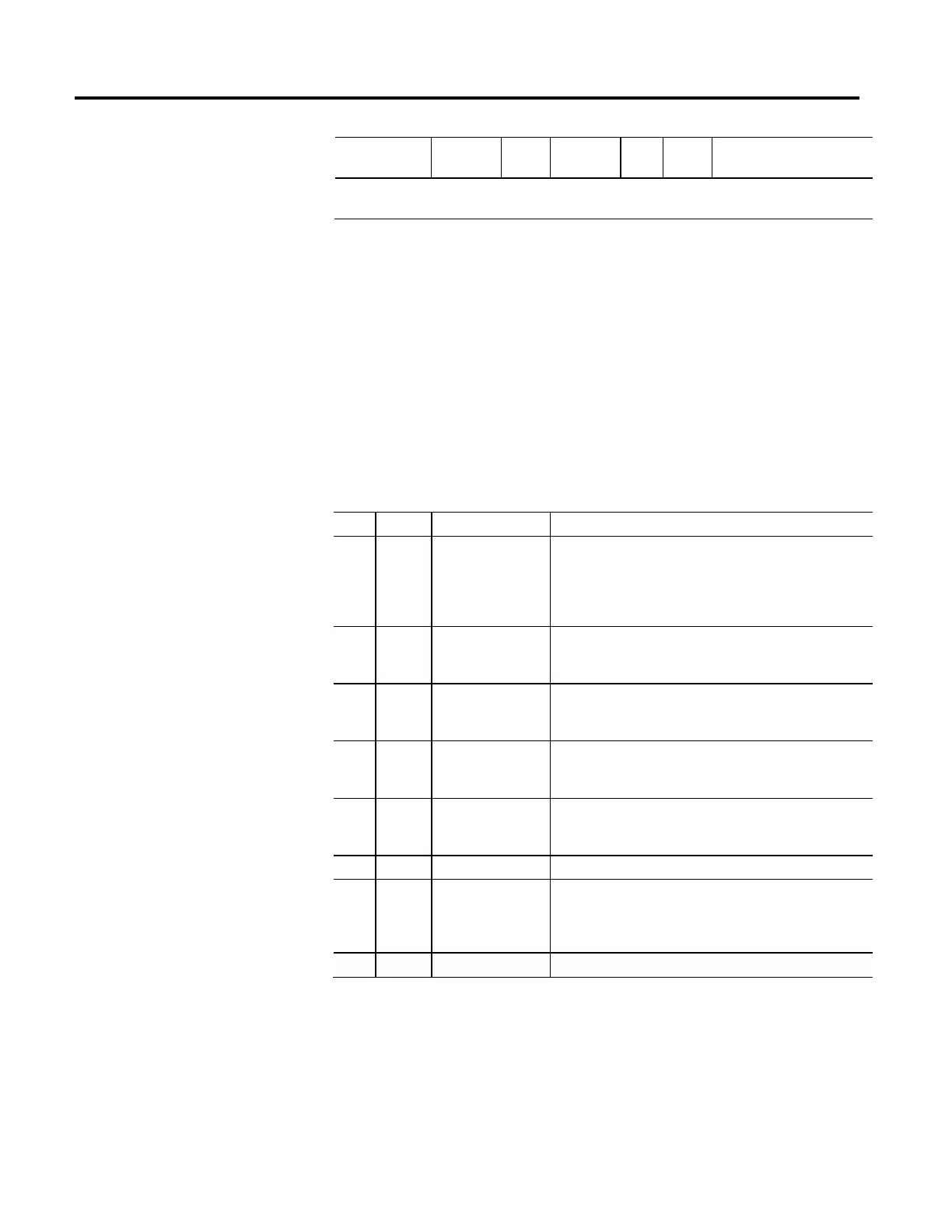

Bit Usage Name Description

0 R/S No Feedback

No

Feedback is selected when sensorless open loop or closed loop control

is desired. When performing open loop control, no feedback signal is

required. In closed loop control, the required feedback signal is

estimated by a sensorless control algorithm based on motor phase

voltage and current signals.

1 R/N Master Feedback

Master Feedback assigns an uncommitted feedback channel to this

device axis instance to serve as a master feedback source when the

device is configured for No Control mode.

2 R/C Motor Feedback

When Motor Feedback is selected, then commutation, acceleration,

velocity, and position feedback signals are all derived from motor

mounted Feedback 1.

3 O/C Load Feedback

When Load Feedback is selected, then motor-mounted Feedback 1 is

only used for PM motor commutation while load-side Feedback 2 is used

for position, velocity, and acceleration.

4 O/P Dual Feedback

When Dual Feedback is selected, then motor mounted Feedback 1 is

used for commutation, acceleration, and velocity, and load-side

Feedback 2 is used strictly for position.

5-7 - Reserved -

8 O/P Dual Integrator Feedback

Dual Integral Feedback means that motor-mounted Feedback 1 is used

for commutation, acceleration, velocity, and position proportional

control, and load-side Feedback 2 is used only for integral position

control. This optimizes the stiffness of the control loop at low frequency.

9-15 - Reserved -

When modified programmatically, using SSV, the Feedback Mode value cannot be

set to an enumeration that the Feedback Configuration cannot support. For

example if the Feedback Configuration is set for Motor Feedback, the Feedback

Mode cannot be changed to Load Feedback since that feedback channel has not

been configured.

Loading...

Loading...