348 Rockwell Automation Publication MOTION-RM003I-EN-P - February 2018

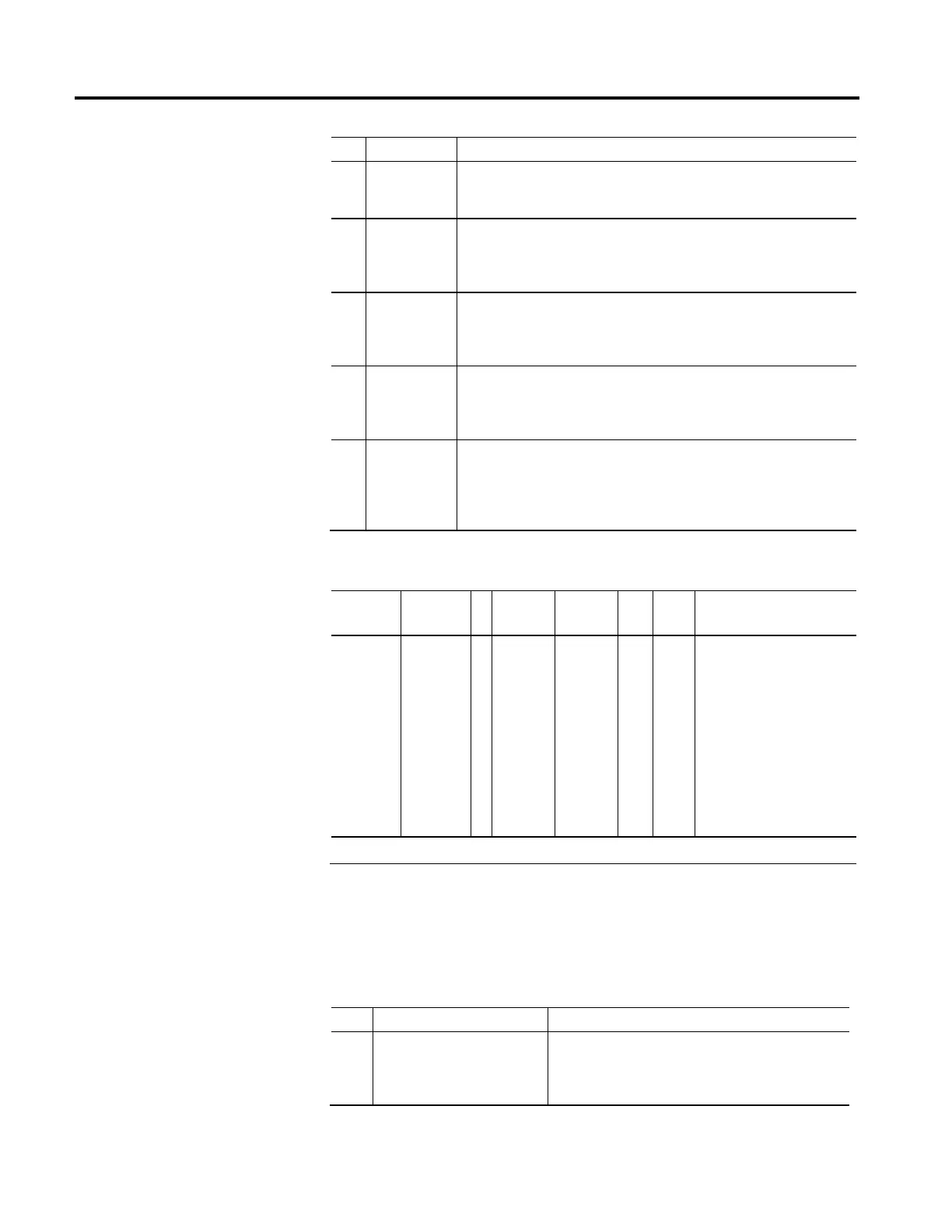

Bit Name Description

4 Motion Fault

If the Motion Fault bit is set, it indicates that one or more fault conditions have occurred

related to the Motion Planner function. The specific fault conditions can then be

determined through access to the Motion Fault attribute of the associated axis.

5 Guard Fault

If the Guard Fault bit is set, it indicates that one or more fault conditions have occurred

related to the Guard Motion safety function. The specific fault conditions can then be

determined through access to the Guard Motion attribute of the associated axis. Guard

Faults are only applicable if the drive device is equipped with Guard Safety functionality.

6 Initialization Fault

The Initialization Fault bit is set when initialization of a CIP Motion drive fails for any

reason. Specific information concerning the Initialization Fault may be found either in the

standard CIP Initialization attributes or in the manufacturer specific CIP Initialization Fault

attributes associated with the CIP Drive axis data types.

7 APR Fault

The APR (Absolute Position Recovery) Fault bit is set when during axis configuration the

system is not able to recover the absolute position of the axis. Specific information

concerning the APR Fault may be found either in the standard APR Fault attributes or int

he manufacturer specific APR Fault attributes associated with the CIP Drive axis data types.

8 Safety Fault

If the Safety Fault bit is set, it indicates that there is one or more fault conditions have

occurred related to the axis safety function. The specific fault conditions can then be

determined through access to the Axis Safety Fault attributes of the associated axis. Safety

Faults are only applicable if the motion device supports "Networked" Safety functionality

through a CIP Safety connection.

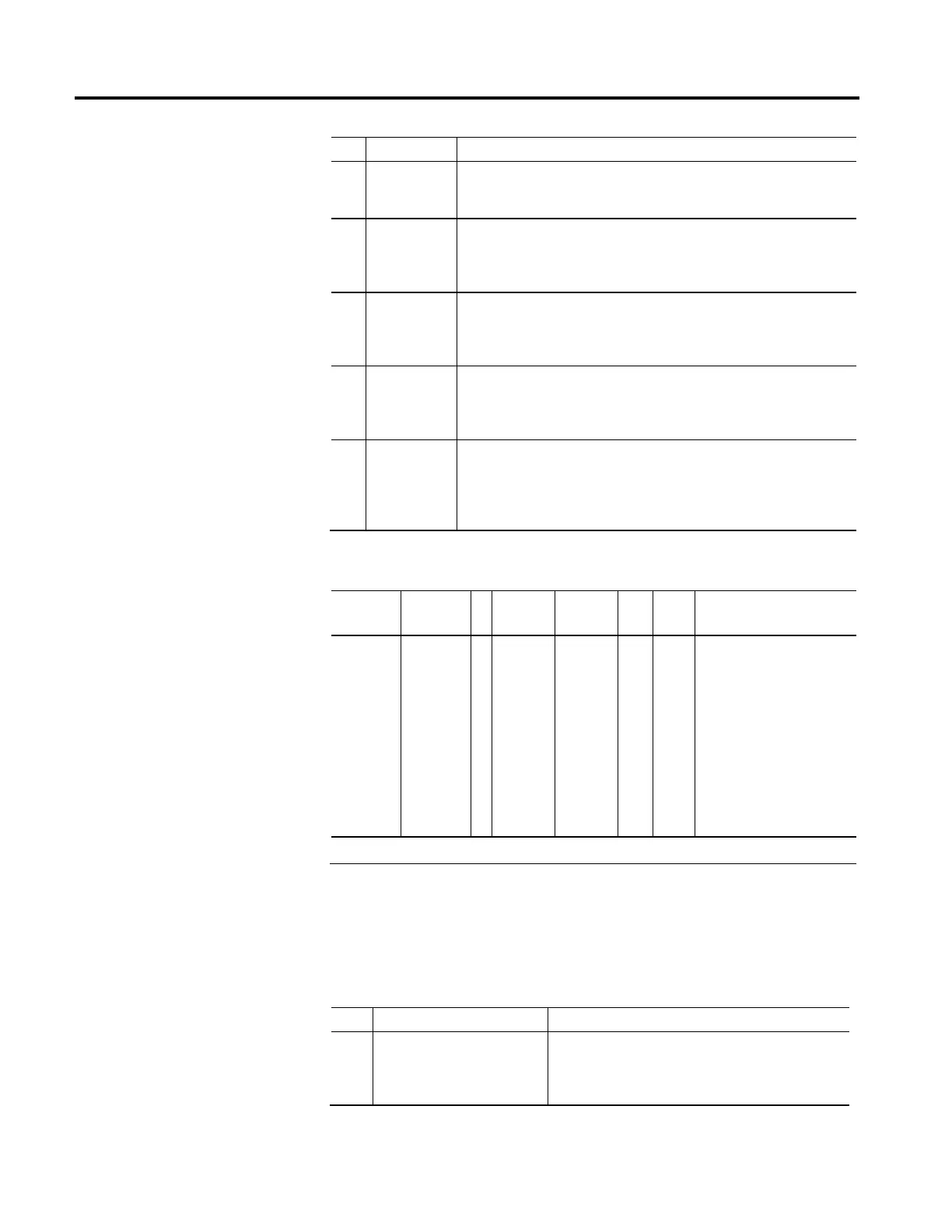

Axis Event Bits

Usage Access T Data Type Default Min Max Semantics of Values

Required - All Get/GSV

1

T DWORD - - - Bitmap - AxisFault

0 = WatchEventArmedStatus

1 = WatchEventStatus

2 = RegEvent1ArmedStatus

3 = RegEvent1Status

4 = RegEvent2ArmedStatus

5 = RegEvent2Status

6 = HomeEventArmedStatus

7 = HomeEventStatus

8... 31= Reserved

1

Direct Tag access is supported. Bit names shown are used as data type member names in the Logix Designer application.

The Axis Event Bit attributes are a collection of basic event conditions. This

attribute is for use primarily by the system during execution of various Motion

Event instructions.

Axis Event Bit Descriptions

Bit Name Description

0 Watch Event Armed Status

The Watch Event Armed Status bit attribute is set when a watch

event has been armed through execution of the MAW (Motion Arm

Watch) instruction. This bit is cleared when either a watch event

occurs or a MDW (Motion Disarm Watch) instruction is executed.

Loading...

Loading...